16MnCr5 Alloy Steel Angle Channel Manufacturers in India, 16MnCr5 Alloy Steel Angle Channels Price, SS 2062 Price per kg, 16MnCr5 Alloy Steel Angle Channel 2062 suppliers, 16MnCr5 Alloy Steel Angle Channels Price, 16MnCr5 Alloy Steel Angle Channel Suppliers in UAE, 16MnCr5 Alloy Steel Angle Channel Suppliers UK, 16MnCr5 Alloy Steel Angle Channel Suppliers in Saudi Arabia, 16MnCr5 Alloy Steel Angle Channel Suppliers in Qatar, 16MnCr5 Alloy Steel Angle Channel Suppliers Australia.

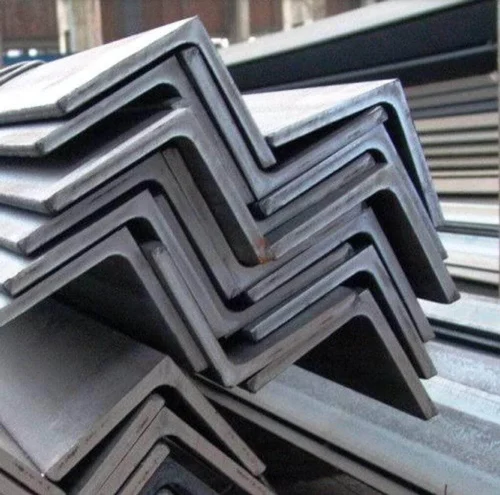

16MnCr5 Alloy Steel Angle Channel is a low-alloy, case-hardening steel used in parts that demand a hard, wear-resistant surface and a tough core. It offers superior toughness and dimensional stability after heat treatment, making it suitable for gears, shafts, and heavy-duty components. This steel provides high fatigue strength and excellent hardenability through carburizing, quenching, and tempering processes. The channel profile adds strength and stability, allowing easy assembly in structural and mechanical designs. Industries prefer 16MnCr5 for its reliable performance and long service life under dynamic loads. It combines economy with engineering versatility for a wide range of industrial uses. The steel's balance of hardness and toughness makes it ideal for complex mechanical systems.

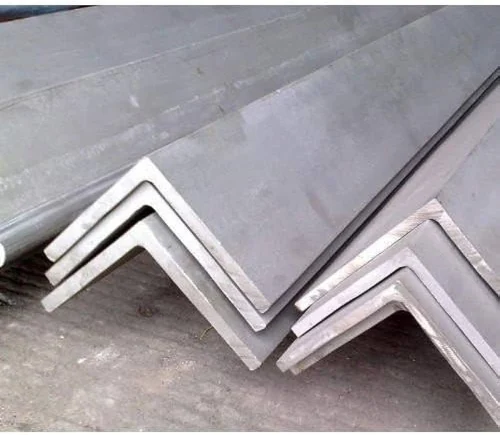

Manufactured according to EN 10084 standards, 16MnCr5 channels feature controlled carbon and manganese content for predictable hardening behavior. Chromium improves hardenability and wear resistance, while manganese enhances strength and toughness. When carburized, the outer layer achieves a surface hardness of up to 60 HRC, providing superior wear protection. The channel structure resists bending and twisting, ideal for mechanical frameworks and welded assemblies. Machinability in the annealed condition is good, ensuring cost-effective fabrication and shaping. These channels are also suitable for induction hardening or surface treatments for enhanced durability. After heat treatment, they maintain strong internal ductility and minimal distortion for precision applications.

16MnCr5 Alloy Steel Angle Channels are widely used in automotive, gear, and machinery manufacturing industries. They are chosen for components such as crankshafts, connecting rods, couplings, and heavy frames. The material’s combination of a tough core and hard case enhances service life under repeated stress. When used as angle channels, the shape provides efficient load-bearing support with structural rigidity. Its metallurgical properties ensure consistent hardness penetration and fatigue resistance. Components made from this alloy perform reliably even in harsh industrial environments. The steel can be readily machined, welded, or heat-treated depending on end-use requirements.

In terms of processing, 16MnCr5 channels respond well to carburizing, quenching, and tempering cycles. Carburizing introduces carbon into the surface layer, improving surface hardness and wear life. Controlled heat treatment prevents excessive grain growth, ensuring a fine and uniform microstructure. The tough, ductile core retains impact strength while the surface resists frictional wear. These channels can be supplied in annealed, normalized, or fully hardened and tempered conditions. They are suitable for surface finishing operations like grinding, polishing, and machining. Uniform heat treatment ensures stable dimensions and reduced residual stresses during service.

Structural engineers and designers value 16MnCr5 for its predictable heat-treatment response and consistent quality. The steel’s balanced composition ensures minimal distortion during carburizing or quenching. It offers dependable strength, stability, and wear resistance for safety-critical assemblies. The material can handle both static and dynamic loads in high-performance equipment. 16MnCr5 channels are available in a variety of sizes and thicknesses for flexible fabrication. Custom cut lengths and special profiles can be supplied for project-specific requirements. It’s a cost-effective alloy that delivers superior service in challenging mechanical environments.

16MnCr5 Alloy Steel Angle Channels comply with global standards, including EN 10084 and DIN 1.7131. Equivalent international grades include AISI 5115 and SAE 5115, sharing similar mechanical behavior. The material’s surface hardness and case depth depend on carburizing time and temperature control. Tensile strength and elongation can be tailored by adjusting tempering parameters. Certificates for chemical and mechanical properties ensure compliance with technical specifications. Non-destructive and microstructural testing can confirm consistency for critical applications. Manufacturers offer full traceability and documentation for industrial quality assurance.

When ordering 16MnCr5 Alloy Steel Angle Channel, specify desired size, hardness, and surface condition. Include requirements for heat treatment, carburizing depth, and mechanical properties. Welding, bending, or machining operations should be planned based on the supplied condition. To prevent distortion, preheating and slow cooling are recommended during fabrication. Surface coatings or galvanizing can be applied for added corrosion protection. Select experienced suppliers familiar with carburizing steels to ensure dimensional accuracy. Proper selection and treatment yield channels with long-lasting, reliable performance.

Specification Table

| Property | Details |

|---|---|

| Grade | 16MnCr5 |

| Standard | EN 10084 / DIN 1.7131 / AISI 5115 |

| Product Type | Alloy Steel Angle Channel |

| Manufacturing Process | Hot Rolled / Cold Drawn / Heat Treated |

| Heat Treatment Condition | Annealed / Carburized / Quenched and Tempered |

| Surface Condition | Black, Bright, Polished, or Machined |

| Available Forms | Angle Channel, Round Bar, Flat Bar, and Forged Section |

| Size Range | 25 mm × 25 mm × 3 mm to 200 mm × 200 mm × 12 mm |

| Length | Custom Cut Lengths / Standard 6 to 12 Meters |

| Hardness (After Carburizing) | 55 – 62 HRC (Surface), Core: 25 – 35 HRC |

| Density | 7.85 g/cm³ |

| Heat Treatment Temperature | Carburizing: 880–960°C, Quenching: 820–860°C, Tempering: 150–200°C |

| Applications | Gears, Shafts, Pins, Bushings, Structural Frames, and Machine Parts |

| Certification | EN 10204 3.1 / 3.2, Mill Test Certificate, NDT Reports Available |

Chemical Composition (Typical ranges for SSIS)

Note: Values are typical ranges. Final composition will be confirmed on MTC provided per lot.

| Element | Minimum (%) | Maximum (%) | Typical (%) |

|---|---|---|---|

| Carbon (C) | 0.14 | 0.19 | 0.17 |

| Manganese (Mn) | 1.00 | 1.30 | 1.15 |

| Chromium (Cr) | 0.80 | 1.10 | 0.95 |

| Silicon (Si) | 0.15 | 0.40 | 0.25 |

| Phosphorus (P) | — | 0.025 | 0.020 |

| Sulphur (S) | — | 0.035 | 0.025 |

| Nickel (Ni) | — | 0.30 | 0.10 |

| Copper (Cu) | — | 0.30 | 0.20 |

Mechanical Properties (Typical)

| Property | Condition | Typical Value | Unit |

|---|---|---|---|

| Tensile Strength | Quenched and Tempered | 850 – 1100 | MPa |

| Yield Strength | Quenched and Tempered | 600 – 750 | MPa |

| Elongation | In 50 mm | 12 – 15 | % |

| Impact Strength (Charpy V-Notch) | Normalized | 35 – 45 | J |

| Hardness (Annealed) | Soft Annealed | 180 – 220 | HB |

| Hardness (Carburized Case) | Carburized & Quenched | 55 – 62 | HRC |

| Core Hardness (After Carburizing) | Tempered Core | 25 – 35 | HRC |

| Modulus of Elasticity | — | 210 | GPa |

| Poisson’s Ratio | — | 0.29 | — |

| Density | — | 7.85 | g/cm³ |

Equivalent Grades

| Standard | Equivalent Grade | Country / Region | Remarks |

|---|---|---|---|

| EN Standard | 16MnCr5 | Europe | EN 10084 Carburizing Steel |

| DIN Standard | 1.7131 | Germany | Equivalent material number under DIN system |

| AISI / SAE | 5115 | USA | Close composition and mechanical properties |

| BS Standard | 527M20 | United Kingdom | British equivalent carburizing steel grade |

| JIS Standard | SCr420 | Japan | Similar low alloy carburizing steel |

| ISO | 16MnCr5 | International | ISO 683-17 Standard Grade |

| GOST | 20KhG | Russia | Comparable carburizing alloy steel grade |

| AFNOR | 16MC5 | France | French designation for carburizing steel |

Dimension & Weight Chart (Selected common sizes)

Below is a representative chart showing outside diameter, wall thickness, inside diameter, cross-sectional area of metal and calculated weight per metre (kg/m). Values are calculated using density = 7.93 g/cm³ and are for guidance — use actual MTC values for procurement & engineering.

| Size (mm) | Thickness (mm) | Weight per Meter (kg/m) | Sectional Area (cm²) | Approx. Weight per 6m (kg) |

|---|---|---|---|---|

| 25 × 25 | 3 | 1.12 | 1.43 | 6.72 |

| 30 × 30 | 3 | 1.38 | 1.77 | 8.28 |

| 40 × 40 | 4 | 2.60 | 3.32 | 15.60 |

| 50 × 50 | 5 | 4.05 | 5.16 | 24.30 |

| 65 × 65 | 6 | 6.05 | 7.71 | 36.30 |

| 75 × 75 | 6 | 7.05 | 8.99 | 42.30 |

| 80 × 80 | 8 | 9.80 | 12.50 | 58.80 |

| 100 × 100 | 8 | 12.20 | 15.60 | 73.20 |

| 130 × 130 | 10 | 18.40 | 23.50 | 110.40 |

| 150 × 150 | 12 | 26.90 | 34.30 | 161.40 |

| 200 × 200 | 12 | 35.50 | 45.30 | 213.00 |

Types Of 16MnCr5 Alloy Steel Angal channel

Stainless Steel Angal & channel

Monel 400 Angal & channel

Inconel 600 Angal & channel

Hastelloy Angal & channel

Super Duplex Angal & channel

Duplex Angal & channel

Nickel Angal & channel

Monel K500 Angal & channel

Frequently Asked Questions (FAQ)

What are the main features of 16MnCr5 angle channel?

Key features include excellent carburizing response, high surface hardness after heat treatment, good core toughness, predictable distortion behavior, and reasonable machinability in the annealed condition.

Which industries commonly use 16MnCr5 channels?

Automotive, agricultural machinery, heavy equipment, gearbox and transmission manufacturers, and general engineering fabricators commonly use 16MnCr5 for components subjected to wear and cyclic loading.

Can 16MnCr5 be welded and machined?

Yes. Machining is easiest in the annealed state. Welding is possible but requires correct preheat/interpass control and post-weld tempering or stress relief to avoid HAZ brittleness—use suitable filler metals and low-hydrogen procedures.

What hardness and mechanical properties can be expected after carburizing?

Surface hardness after carburizing and quenching typically reaches 55–62 HRC depending on process; core hardness after tempering is typically 25–35 HRC. Tensile and yield strengths depend on tempering but are high for quenched & tempered conditions.

What international equivalents exist for 16MnCr5?

Common equivalents include DIN 1.7131 (Germany), AISI/SAE 5115 (USA), SCr420 (Japan), BS 527M20 (UK) and GOST 20KhG (Russia). Always confirm equivalence with suppliers for critical applications.

Angle Channels Supplier

Mumbai, Delhi, Kolkata, Chennai, Bengaluru, Hyderabad, Ahmadabad, Pune, Surat, Jaipur, Kanpur, Lucknow, Nagpur, Ghaziabad, Indore, Coimbatore, Kochi, Patna, Kozhikode, Thrissur, Vadodara, Agra, Malappuram, Thiruvananthapuram, Kannur, Ludhiana, Nashik, Noida, Madrid, Sharjah, Moscow, Hong Kong, Lagos, Montreal, Bogota, Los Angeles, New Delhi, Jeddah, Chennai, Kanpur, Edmonton, Istanbul, Bhopal, Calgary, Ulsan, Rio de Janeiro, Colombo, Cairo, Ludhiana, Indore, Thane, Dubai, Seoul, Santiago, Kuwait City, Dammam, Tehran, Busan, Rajkot, Nagpur, La Victoria, Bangkok, Granada, Lahore, Manama

Angle Channels Exporter

16MnCr5 Alloy Steel Angle Channel exporter South Korea, 16MnCr5 Alloy Steel Angle Channel exporter in South Africa, 16MnCr5 Alloy Steel Angle Channel exporter in Sri Lanka, 16MnCr5 Alloy Steel Angle Channel exporter in Syria, 16MnCr5 Alloy Steel Angle Channel exporter in Taiwan, 16MnCr5 Alloy Steel Angle Channel exporter in Tanzania, 16MnCr5 Alloy Steel Angle Channel exporter in Tajikistan, 16MnCr5 Alloy Steel Angle Channel exporter in Thailand, 16MnCr5 Alloy Steel Angle Channel exporter in Turkey, 16MnCr5 Alloy Steel Angle Channel exporter in Turkmenistan, 16MnCr5 Alloy Steel Angle Channel exporter in Ukraine, 16MnCr5 Alloy Steel Angle Channel exporter in United Kingdom, 16MnCr5 Alloy Steel Angle Channel exporter in United Arab Emirates (UAE), 16MnCr5 Alloy Steel Angle Channel exporter in Uzbekistan, 16MnCr5 Alloy Steel Angle Channel exporter in Vietnam, 16MnCr5 Alloy Steel Angle Channel exporter in Yemen, 16MnCr5 Alloy Steel Angle Channel exporter in France, 16MnCr5 Alloy Steel Angle Channel exporter in Germany, 16MnCr5 Alloy Steel Angle Channel exporter in Greece, 16MnCr5 Alloy Steel Angle Channel exporter in Oman, 16MnCr5 Alloy Steel Angle Channel exporter in Colombia, 16MnCr5 Alloy Steel Angle Channel exporter in Portugal, 16MnCr5 Alloy Steel Angle Channel exporter in Japan, 16MnCr5 Alloy Steel Angle Channel exporter in Lithuania, 16MnCr5 Alloy Steel Angle Channel exporter in Macau, 16MnCr5 Alloy Steel Angle Channel exporter in Mongolia, 16MnCr5 Alloy Steel Angle Channel exporter in Qatar, 16MnCr5 Alloy Steel Angle Channel exporter in Ireland, 16MnCr5 Alloy Steel Angle Channel exporter in Malaysia, 16MnCr5 Alloy Steel Angle Channel exporter in Bangladesh, 16MnCr5 Alloy Steel Angle Channel exporter in United Kingdom, 16MnCr5 Alloy Steel Angle Channel exporter in Russia, 16MnCr5 Alloy Steel Angle Channel exporter in Iran, 16MnCr5 Alloy Steel Angle Channel exporter in Vietnam, 16MnCr5 Alloy Steel Angle Channel exporter in Jordan, 16MnCr5 Alloy Steel Angle Channel exporter in Yemen, 16MnCr5 Alloy Steel Angle Channel exporter in South Africa, 16MnCr5 Alloy Steel Angle Channel exporter in Singapore, 16MnCr5 Alloy Steel Angle Channel exporter in Sri Lanka, 16MnCr5 Alloy Steel Angle Channel exporter in Thailand, 16MnCr5 Alloy Steel Angle Channel exporter in Bulgaria, 16MnCr5 Alloy Steel Angle Channel exporter in Poland, 16MnCr5 Alloy Steel Angle Channel exporter in Denmark, 16MnCr5 Alloy Steel Angle Channel exporter in Nigeria, 16MnCr5 Alloy Steel Angle Channel exporter in Gambia, 16MnCr5 Alloy Steel Angle Channel exporter in Indonesia, 16MnCr5 Alloy Steel Angle Channel exporter in Finland, 16MnCr5 Alloy Steel Angle Channel exporter in Argentina, 16MnCr5 Alloy Steel Angle Channel exporter in Chile, 16MnCr5 Alloy Steel Angle Channel exporter in Spain, 16MnCr5 Alloy Steel Angle Channel exporter in Peru, 16MnCr5 Alloy Steel Angle Channel exporter in Kuwait, 16MnCr5 Alloy Steel Angle Channel exporter in India, 16MnCr5 Alloy Steel Angle Channel exporter in Saudi Arabia, 16MnCr5 Alloy Steel Angle Channel exporter in Slovakia, 16MnCr5 Alloy Steel Angle Channel exporter in Slovenia, 16MnCr5 Alloy Steel Angle Channel exporter in Spain, 16MnCr5 Alloy Steel Angle Channel exporter in Sweden, 16MnCr5 Alloy Steel Angle Channel exporter in Switzerland, 16MnCr5 Alloy Steel Angle Channel exporter in Singapore

People Also Search For

16MnCr5 Sheets Supplier India, 16MnCr5 Coils Supplier India, SS 304 coil price list, 16MnCr5 304 cold rolled coil distributors, 16MnCr5 304 profile dealers, 16MnCr5 304 circle price list, 16MnCr5 304 coil exporter in mumbai, ss 304 coil Supplier in India, 16MnCr5 304 coil exporter in india, 16MnCr5 304 coil-circle exporter in mumbai, ss 304 blank suppliers, 16MnCr5 304 coils price, ss 304 circle price list, astm a240 ss 304 circles exporter, ss 304 shim coils, 16MnCr5 304 coil supplier in mumbai, 16MnCr5 Plates Supplier India, , ss 304 coil cheap price, high quality ss 304 coils stockholder in mumbai india.