Aluminium 1100 Angle Channel Manufacturers in India, Aluminium 1100 Angle Channels Price, SS 2062 Price per kg, Aluminium 1100 Angle Channel 2062 suppliers, Aluminium 1100 Angle Channels Price, Aluminium 1100 Angle Channel Suppliers in UAE, Aluminium 1100 Angle Channel Suppliers UK, Aluminium 1100 Angle Channel Suppliers in Saudi Arabia, Aluminium 1100 Angle Channel Suppliers in Qatar, Aluminium 1100 Angle Channel Suppliers Australia.

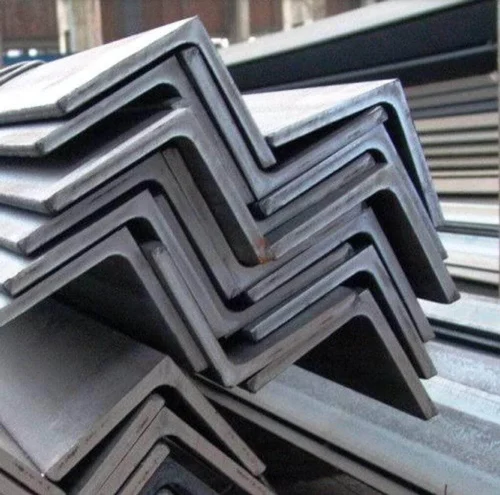

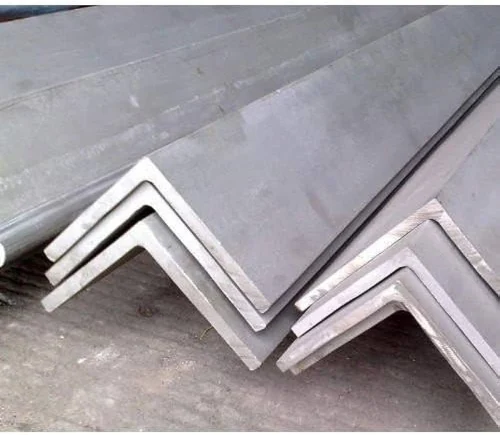

Aluminium 1100 Angle & Channel are among the most widely used commercially pure aluminum products. Composed of 99% pure aluminum, these sections are known for their excellent corrosion resistance, formability, and high thermal conductivity. They are particularly suited for applications that do not require high strength but demand superior ductility and workability. Due to their smooth surface finish and ability to be easily fabricated, Aluminium 1100 Angles & Channels are ideal for architectural, decorative, and general industrial uses. Their lightweight nature makes them easy to transport and install while reducing overall project weight.

One of the primary advantages of Aluminium 1100 Angles & Channels is their exceptional resistance to atmospheric corrosion. These profiles perform remarkably well in marine and industrial environments, where other metals might degrade or rust. The natural oxide film formed on the surface enhances protection, making them ideal for both indoor and outdoor applications. Furthermore, Aluminium 1100 can be easily anodized to enhance aesthetic appeal or provide additional surface protection. Its resistance to chemicals and environmental conditions makes it an excellent choice for chemical handling equipment and food processing plants.

In terms of workability, Aluminium 1100 Angles & Channels are unmatched among aluminum alloys. They exhibit superior forming characteristics, allowing easy bending, stamping, and spinning without cracking or breaking. This makes them suitable for intricate fabrications and complex structures. The alloy can also be joined by conventional welding methods, including gas and arc welding. Moreover, it is well-suited for soldering and brazing processes, providing flexibility in manufacturing diverse industrial components and assemblies. Its compatibility with various fabrication methods ensures versatility across multiple industries.

Aluminium 1100 Angles & Channels are often used in the manufacturing of reflectors, decorative trim, nameplates, and chemical storage equipment. Their clean, bright appearance and non-magnetic properties make them an excellent choice for both functional and aesthetic applications. In addition, these profiles are commonly utilized in heat exchangers and HVAC systems due to their superior thermal conductivity. The alloy’s lightweight structure also contributes to energy efficiency in transportation and construction sectors, where reducing load without compromising durability is a priority.

From an economic standpoint, Aluminium 1100 offers great value due to its combination of performance and cost-effectiveness. Since it is one of the purest forms of aluminum, it requires less processing and alloying, leading to lower production costs. Its recyclability further enhances its environmental benefits, as aluminum can be reused indefinitely without losing quality. This makes Aluminium 1100 Angles & Channels an environmentally responsible choice in modern manufacturing and green construction projects. They contribute significantly to sustainable design and resource conservation initiatives globally.

When it comes to machining, Aluminium 1100 Angles & Channels exhibit fair machinability compared to harder aluminum alloys. While it may not be suitable for applications requiring extremely tight tolerances or high-strength performance, it excels in areas where corrosion resistance, formability, and conductivity are key. Typical finishing processes like polishing, anodizing, and powder coating further enhance its durability and visual appeal. These attributes make Aluminium 1100 an indispensable material in industries such as electrical, architectural, marine, and consumer goods manufacturing.

In conclusion, Aluminium 1100 Angle & Channel stand out as a premium choice for lightweight, corrosion-resistant, and formable applications. Their versatility allows them to be used in a wide range of structural, decorative, and functional projects. Whether in architectural frameworks, industrial equipment, or artistic installations, these profiles deliver consistent performance and aesthetic excellence. Combined with their eco-friendly nature and long service life, Aluminium 1100 Angles & Channels continue to be a preferred solution for engineers, designers, and builders seeking reliability and sustainability.

Specification Table

| Property | Specification / Typical Value | Notes |

|---|---|---|

| Alloy Designation | Aluminium 1100 (UNS A91100) | Commercially pure aluminium — commonly supplied in O (annealed) temper. |

| Product Forms | Extruded Angles & Channels | Custom cross-sections available to order. |

| Temper / Condition | O (annealed); H-series tempers available on request | 1100 is typically soft and highly formable. |

| Standards | Common: ASTM B209, EN & ISO equivalents (check for extrusions) | Standards vary by region and product form — verify with supplier. |

| Density | ≈ 2.71 g/cm³ (2710 kg/m³) | Useful for weight & mass calculations. |

| Melting Range | ~630–650 °C | Approximate melting range for commercially pure Al. |

| Electrical Conductivity | ~34–36% IACS (typical) | Good conductivity for electrical applications where high strength isn't required. |

| Thermal Conductivity | ~222 W/m·K (room temperature, typical) | Excellent for heat-sinking and thermal applications. |

| Tensile Strength (Typical) | ~70–125 MPa (depends on temper) | Values vary by temper; O (annealed) at lower end. |

| Yield Strength (Typical) | ~40–60 MPa (depends on temper) | Not recommended for high-load structural uses without margin. |

| Elongation | ~10–30% (depends on temper & cross-section) | High ductility — easy to form and bend. |

| Surface Finish | Mill finish standard; anodized/painted on request | Anodizing improves appearance and corrosion protection. |

| Corrosion Resistance | Excellent in atmospheric & mildly corrosive environments | Not recommended for strong acidic/alkaline exposures without protection. |

| Typical Applications | Architectural trim, reflectors, decorative framing, electrical enclosures, heat sinks | Used where formability, conductivity & corrosion resistance are prioritized over strength. |

| Manufacturing Notes | Extrudable to varied cross-sections; cut, formed, welded & joined easily | Confirm dimensional tolerances & straightness with supplier for long sections. |

| Typical Dimensional Tolerances | Supplier/section dependent; e.g., ±0.5 mm for small extrusions | Exact tolerances depend on die, cross-section & order quantity. |

| Recyclability | 100% recyclable without loss of properties | Recycling reduces energy use and environmental impact. |

Chemical Composition (Typical ranges for SSIS)

Note: Values are typical ranges. Final composition will be confirmed on MTC provided per lot.

| Element | Percentage (%) | Remarks |

|---|---|---|

| Aluminium (Al) | 99.00 min | Primary constituent — gives purity and corrosion resistance. |

| Copper (Cu) | 0.05 – 0.20 | Improves strength slightly and enhances hardness. |

| Iron (Fe) | 0.00 – 0.95 | Common impurity within specification limits. |

| Silicon (Si) | 0.00 – 0.45 | Improves casting and machining characteristics. |

| Zinc (Zn) | 0.00 – 0.10 | Minor impurity with negligible effect on properties. |

| Manganese (Mn) | 0.00 – 0.05 | Helps improve strength marginally and refines grain structure. |

| Magnesium (Mg) | 0.00 – 0.05 | Traces may improve corrosion resistance slightly. |

| Other Elements (each) | 0.00 – 0.05 | Includes trace impurities such as Ti, Cr, Ni, etc. |

| Total Others | 0.15 max | Total of all minor impurities combined. |

Mechanical Properties (Typical)

| Property | Typical Value | Condition / Temper | Remarks |

|---|---|---|---|

| Tensile Strength | 70 – 125 MPa | O / H12 / H14 | Varies with temper; soft in O condition, stronger in H14. |

| Yield Strength (0.2% Proof) | 40 – 60 MPa | O / H12 / H14 | Low yield; allows easy forming and bending operations. |

| Elongation | 10 – 30% | O / H12 / H14 | High ductility; ideal for spinning, stamping, and drawing. |

| Hardness (Brinell HB) | 20 – 35 HB | Varies by temper | Soft in annealed condition; increases in work-hardened state. |

| Modulus of Elasticity | 69 GPa | — | Typical for pure aluminium alloys. |

| Shear Strength | 45 MPa | O Temper | Suitable for light structural applications. |

| Poisson’s Ratio | 0.33 | — | Constant across all tempers. |

| Fatigue Strength | 35 MPa | — | At 5 × 10⁸ cycles (approximate value for O temper). |

| Thermal Expansion Coefficient | 23.6 × 10⁻⁶ /°C | 20–100°C range | Indicates expansion with temperature increase. |

| Thermal Conductivity | ~222 W/m·K | — | Excellent for heat sinks and thermal systems. |

| Electrical Conductivity | 34–36% IACS | — | Good for electrical and thermal transfer uses. |

| Density | 2.71 g/cm³ | — | Lightweight for high formability and low mass applications. |

Equivalent Grades

| Standard | Equivalent Grade | Description / Notes |

|---|---|---|

| UNS (Unified Numbering System) | A91100 | Universal designation for Aluminium 1100 alloy. |

| ISO | Al99.0 | International designation denoting 99% pure aluminium. |

| EN (European Standard) | EN AW-1100 | European standard equivalent for Aluminium 1100 alloy. |

| BS (British Standard) | 3103 (Al99.0) | Equivalent in BS system, with similar chemical composition. |

| JIS (Japanese Standard) | A1100 | Japanese Industrial Standard for Aluminium 1100. |

| DIN (German Standard) | Al99.0 | Denotes 99% minimum aluminium purity under DIN norms. |

| AFNOR (French Standard) | Al99 | Used in French standard classification for pure aluminium. |

| GOST (Russian Standard) | АД00 | Closest equivalent in Russian standards for pure aluminium grades. |

Dimension & Weight Chart (Selected common sizes)

Below is a representative chart showing outside diameter, wall thickness, inside diameter, cross-sectional area of metal and calculated weight per metre (kg/m). Values are calculated using density = 7.93 g/cm³ and are for guidance — use actual MTC values for procurement & engineering.

| Size (mm) | Thickness (mm) | Length (m) | Weight per Meter (kg/m) | Approx. Weight per 6m (kg) |

|---|---|---|---|---|

| 20 × 20 | 3 | 6 | 0.29 | 1.74 |

| 25 × 25 | 3 | 6 | 0.36 | 2.16 |

| 30 × 30 | 3 | 6 | 0.43 | 2.58 |

| 40 × 40 | 4 | 6 | 0.78 | 4.68 |

| 50 × 50 | 5 | 6 | 1.20 | 7.20 |

| 65 × 65 | 6 | 6 | 1.80 | 10.80 |

| 75 × 75 | 6 | 6 | 2.10 | 12.60 |

| 100 × 100 | 8 | 6 | 3.90 | 23.40 |

Types Of Aluminium 1100 Angal channel

Stainless Steel Angal & channel

Monel 400 Angal & channel

Inconel 600 Angal & channel

Aluminium Bronze Angal & channel

Super Duplex Angal & channel

Duplex Angal & channel

Nickel Angal & channel

Monel K500 Angal & channel

Frequently Asked Questions (FAQ)

What is Aluminium 1100 used for?

Aluminium 1100 is primarily used for applications requiring excellent corrosion resistance and high thermal and electrical conductivity. It is commonly used in decorative trim, reflectors, heat exchangers, and chemical equipment.

What are the key properties of Aluminium 1100 Angle & Channel?

Aluminium 1100 offers outstanding corrosion resistance, good formability, and weldability. However, it has relatively low strength compared to other aluminium alloys, making it ideal for non-structural and lightweight applications.

Can Aluminium 1100 Angle & Channel be anodized?

Yes, Aluminium 1100 can be anodized to enhance surface finish, corrosion resistance, and reflectivity. The anodized surface also improves its aesthetic appeal for architectural and decorative uses.

Is Aluminium 1100 suitable for welding and brazing?

Yes, Aluminium 1100 is highly suitable for both welding and brazing. It can be easily joined using conventional methods, making it an excellent choice for fabrication and assembly projects.

What are the typical applications of Aluminium 1100 Angles and Channels?

Common applications include HVAC systems, chemical handling equipment, heat exchangers, roofing, signage frames, and lightweight architectural components due to its excellent corrosion resistance and malleability.

Angle Channels Supplier

Mumbai, Delhi, Kolkata, Chennai, Bengaluru, Hyderabad, Ahmadabad, Pune, Surat, Jaipur, Kanpur, Lucknow, Nagpur, Ghaziabad, Indore, Coimbatore, Kochi, Patna, Kozhikode, Thrissur, Vadodara, Agra, Malappuram, Thiruvananthapuram, Kannur, Ludhiana, Nashik, Noida, Madrid, Sharjah, Moscow, Hong Kong, Lagos, Montreal, Bogota, Los Angeles, New Delhi, Jeddah, Chennai, Kanpur, Edmonton, Istanbul, Bhopal, Calgary, Ulsan, Rio de Janeiro, Colombo, Cairo, Ludhiana, Indore, Thane, Dubai, Seoul, Santiago, Kuwait City, Dammam, Tehran, Busan, Rajkot, Nagpur, La Victoria, Bangkok, Granada, Lahore, Manama

Angle Channels Exporter

Aluminium 1100 Angle Channel exporter South Korea, Aluminium 1100 Angle Channel exporter in South Africa, Aluminium 1100 Angle Channel exporter in Sri Lanka, Aluminium 1100 Angle Channel exporter in Syria, Aluminium 1100 Angle Channel exporter in Taiwan, Aluminium 1100 Angle Channel exporter in Tanzania, Aluminium 1100 Angle Channel exporter in Tajikistan, Aluminium 1100 Angle Channel exporter in Thailand, Aluminium 1100 Angle Channel exporter in Turkey, Aluminium 1100 Angle Channel exporter in Turkmenistan, Aluminium 1100 Angle Channel exporter in Ukraine, Aluminium 1100 Angle Channel exporter in United Kingdom, Aluminium 1100 Angle Channel exporter in United Arab Emirates (UAE), Aluminium 1100 Angle Channel exporter in Uzbekistan, Aluminium 1100 Angle Channel exporter in Vietnam, Aluminium 1100 Angle Channel exporter in Yemen, Aluminium 1100 Angle Channel exporter in France, Aluminium 1100 Angle Channel exporter in Germany, Aluminium 1100 Angle Channel exporter in Greece, Aluminium 1100 Angle Channel exporter in Oman, Aluminium 1100 Angle Channel exporter in Colombia, Aluminium 1100 Angle Channel exporter in Portugal, Aluminium 1100 Angle Channel exporter in Japan, Aluminium 1100 Angle Channel exporter in Lithuania, Aluminium 1100 Angle Channel exporter in Macau, Aluminium 1100 Angle Channel exporter in Mongolia, Aluminium 1100 Angle Channel exporter in Qatar, Aluminium 1100 Angle Channel exporter in Ireland, Aluminium 1100 Angle Channel exporter in Malaysia, Aluminium 1100 Angle Channel exporter in Bangladesh, Aluminium 1100 Angle Channel exporter in United Kingdom, Aluminium 1100 Angle Channel exporter in Russia, Aluminium 1100 Angle Channel exporter in Iran, Aluminium 1100 Angle Channel exporter in Vietnam, Aluminium 1100 Angle Channel exporter in Jordan, Aluminium 1100 Angle Channel exporter in Yemen, Aluminium 1100 Angle Channel exporter in South Africa, Aluminium 1100 Angle Channel exporter in Singapore, Aluminium 1100 Angle Channel exporter in Sri Lanka, Aluminium 1100 Angle Channel exporter in Thailand, Aluminium 1100 Angle Channel exporter in Bulgaria, Aluminium 1100 Angle Channel exporter in Poland, Aluminium 1100 Angle Channel exporter in Denmark, Aluminium 1100 Angle Channel exporter in Nigeria, Aluminium 1100 Angle Channel exporter in Gambia, Aluminium 1100 Angle Channel exporter in Indonesia, Aluminium 1100 Angle Channel exporter in Finland, Aluminium 1100 Angle Channel exporter in Argentina, Aluminium 1100 Angle Channel exporter in Chile, Aluminium 1100 Angle Channel exporter in Spain, Aluminium 1100 Angle Channel exporter in Peru, Aluminium 1100 Angle Channel exporter in Kuwait, Aluminium 1100 Angle Channel exporter in India, Aluminium 1100 Angle Channel exporter in Saudi Arabia, Aluminium 1100 Angle Channel exporter in Slovakia, Aluminium 1100 Angle Channel exporter in Slovenia, Aluminium 1100 Angle Channel exporter in Spain, Aluminium 1100 Angle Channel exporter in Sweden, Aluminium 1100 Angle Channel exporter in Switzerland, Aluminium 1100 Angle Channel exporter in Singapore

People Also Search For

SS Sheets Supplier India, SS Coils Supplier India, SS 304 coil price list, SS 304 cold rolled coil distributors, SS 304 profile dealers, SS 304 circle price list, SS 304 coil exporter in mumbai, ss 304 coil Supplier in India, SS 304 coil exporter in india, SS 304 coil-circle exporter in mumbai, ss 304 blank suppliers, SS 304 coils price, ss 304 circle price list, astm a240 ss 304 circles exporter, ss 304 shim coils, SS 304 coil supplier in mumbai, SS Plates Supplier India, , ss 304 coil cheap price, high quality ss 304 coils stockholder in mumbai india.