Aluminium 6082 Angle Channel Manufacturers in India, Aluminium 6082 Angle Channels Price, SS 2062 Price per kg, Aluminium 6082 Angle Channel 2062 suppliers, Aluminium 6082 Angle Channels Price, Aluminium 6082 Angle Channel Suppliers in UAE, Aluminium 6082 Angle Channel Suppliers UK, Aluminium 6082 Angle Channel Suppliers in Saudi Arabia, Aluminium 6082 Angle Channel Suppliers in Qatar, Aluminium 6082 Angle Channel Suppliers Australia.

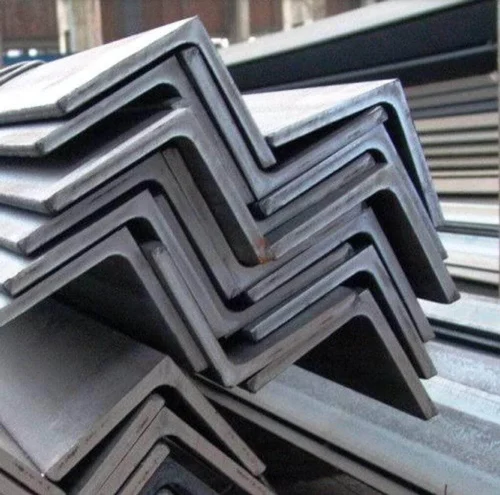

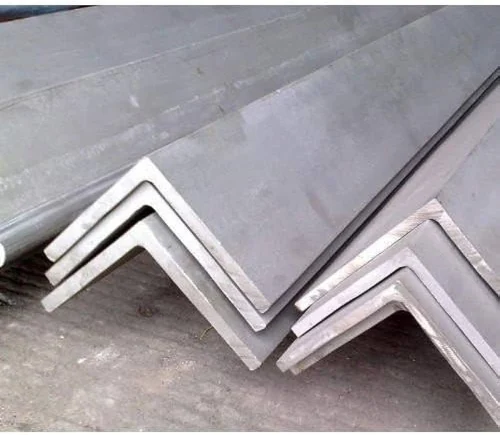

Aluminium 6082 Angle & Channel is one of the most popular structural alloys from the 6000 series, known for its excellent strength, corrosion resistance, and machinability. It is an aluminium–magnesium–silicon alloy that provides outstanding performance in both indoor and outdoor environments. Due to its superior mechanical properties, Aluminium 6082 is often referred to as a structural alloy. It finds extensive use in load-bearing applications where high tensile strength and lightweight design are crucial. The alloy also exhibits good surface finish and is suitable for anodizing.

This alloy offers a fine balance between strength and workability, making Aluminium 6082 Angles & Channels ideal for fabrications that require precision cutting, welding, and forming. It can be easily machined to tight tolerances without losing its dimensional stability. The alloy’s silicon and magnesium content enhance its hardness and resistance to wear. Engineers and fabricators prefer Aluminium 6082 over 6061 in many cases because of its higher strength. Its excellent corrosion resistance makes it particularly useful in marine and industrial environments.

Aluminium 6082 Angle & Channel sections are widely used in architectural structures, frames, bridges, transport, and construction projects. They are also utilized in scaffolding systems, cranes, and trusses due to their lightweight yet robust characteristics. The alloy’s high strength-to-weight ratio makes it an excellent alternative to heavier steel materials, contributing to reduced structural load and improved energy efficiency. Additionally, its good formability allows it to be extruded into various complex shapes.

Welding performance is another strong point of Aluminium 6082. It can be welded using TIG or MIG processes without significant loss in mechanical properties. Post-weld strength, however, may be slightly lower compared to the parent material, which can be compensated by heat treatment. The alloy retains good toughness even at low temperatures, ensuring reliability in harsh conditions. Its non-magnetic nature also makes it suitable for electronic and sensitive equipment housings.

In terms of finishing, Aluminium 6082 Angle & Channel responds well to both anodizing and powder coating. This provides designers the freedom to achieve decorative appearances along with additional corrosion protection. It is often chosen for applications requiring high visual appeal, such as in furniture frames, railings, and automotive trims. The anodized surface enhances hardness and extends the component’s service life, making it a cost-effective and durable solution.

Mechanical properties of Aluminium 6082 depend on the temper type. The T6 temper offers the highest strength among all tempers, achieved through solution heat treatment and artificial aging. This makes 6082-T6 ideal for structural applications where rigidity and durability are key. Meanwhile, the T4 and T5 tempers provide improved formability for applications that involve complex bending or shaping before final hardening. Its high yield strength ensures stability under heavy loads and long-term service.

Overall, Aluminium 6082 Angle & Channel combines strength, versatility, and corrosion resistance in a lightweight form. Whether in marine environments, heavy machinery, transportation, or architectural frameworks, it delivers reliable performance and longevity. Its adaptability across industries highlights why Aluminium 6082 is one of the most trusted structural alloys available today. With proper fabrication and finishing, it ensures both aesthetic and functional excellence for a wide range of engineering applications.

Specification Table

| Property | Value / Typical | Standard / Note |

|---|---|---|

| Alloy designation | 6082 | EN AW-6082 |

| UNS / Alternate | A96082 | Common alternative designation |

| Composition system | Al–Mg–Si (primary alloying elements) | Part of 6xxx series |

| Typical tempers | T6, T651, T4, T5 | T6 / T651 widely used for structural applications |

| Product forms (Angles & Channels) | Extruded angle sections, U-channels, C-channels, custom extrusions | Extrusion per dimensional requirements |

| Density | ≈ 2.70 g/cm³ (2700 kg/m³) | Typical value for aluminium alloys |

| Melting range (approx.) | ~555 °C — 645 °C | Solidus to liquidus range (typical) |

| Young's modulus (Elastic modulus) | ≈ 69 GPa | Engineering design value |

| Common standards (chemical & physical) | EN 573-3 (chemical composition), EN 755 / EN 12020 (extruded products) | Refer to specific standard editions for certs |

| Typical applications | Structural frames, trusses, transport components, architectural profiles, marine fittings | Preferred where high strength-to-weight is needed |

| Surface finish / Treatment | Mill finish, anodized, powder coated | Can be post-processed for corrosion & aesthetics |

| Heat treatability | Heat-treatable (solution heat treat + artificial age for T6) | Controls final strength & hardness |

| Inspection / Testing | Mechanical testing, dimensional inspection, chemical analysis on request | As per purchaser / project specification |

Chemical Composition (Typical ranges for SSIS)

Note: Values are typical ranges. Final composition will be confirmed on MTC provided per lot.

| Element | Minimum (%) | Maximum (%) | Typical Role |

|---|---|---|---|

| Silicon (Si) | 0.70 | 1.30 | Improves strength and enhances response to heat treatment |

| Iron (Fe) | — | 0.50 | Impurity control; excessive Fe reduces ductility |

| Copper (Cu) | — | 0.10 | Increases hardness and machinability slightly |

| Manganese (Mn) | 0.40 | 1.00 | Improves strength and resistance to fatigue |

| Magnesium (Mg) | 0.60 | 1.20 | Provides solid solution strengthening and corrosion resistance |

| Chromium (Cr) | — | 0.25 | Improves toughness and resistance to stress corrosion cracking |

| Zinc (Zn) | — | 0.20 | Minor element; can affect corrosion behavior |

| Titanium (Ti) | — | 0.10 | Refines grain structure during solidification |

| Other (each) | — | 0.05 | Trace residual elements |

| Other (total) | — | 0.15 | Maximum total of unspecified elements |

| Aluminium (Al) | Balance | Main constituent providing lightweight and corrosion resistance | |

Mechanical Properties (Typical)

| Property | T4 Temper | T6 Temper | T651 Temper | Test Standard / Note |

|---|---|---|---|---|

| Tensile Strength (MPa) | 180 – 250 | 290 – 340 | 300 – 340 | EN 755-2 / ASTM B221 |

| Yield Strength (0.2% Proof) (MPa) | 110 – 150 | 240 – 280 | 250 – 290 | EN 755-2 / ASTM B221 |

| Elongation (% in 50 mm) | 10 – 16 | 6 – 10 | 6 – 8 | Dependent on section thickness |

| Brinell Hardness (HB) | 60 – 80 | 90 – 100 | 95 – 105 | Typical range for 10 mm ball / 500 kg load |

| Modulus of Elasticity (GPa) | ≈ 69 | Typical for aluminium alloys | ||

| Shear Strength (MPa) | 100 | 200 | 205 | Approximate design values |

| Poisson’s Ratio | 0.33 | Constant across tempers | ||

| Fatigue Strength (MPa) | 90 | 95 | 100 | Rotating beam test at 5×10⁸ cycles |

| Melting Point (°C) | 555 – 645 | Solidus–Liquidus range | ||

| Density (g/cm³) | 2.70 | Standard aluminium alloy density | ||

Equivalent Grades

| Standard | Equivalent Grade / Designation | Remarks |

|---|---|---|

| UNS | A96082 | Unified Numbering System designation |

| ISO | AlSi1MgMn | International standard chemical designation |

| EN (Europe) | EN AW-6082 | European aluminium designation system (EN 573-3) |

| BS (United Kingdom) | HE30 | Former British standard equivalent (BS 1474) |

| AFNOR (France) | AlMgSi1Mn | AFNOR designation in French standards |

| DIN (Germany) | AlMgSi1 | DIN 3.2315 designation |

| JIS (Japan) | A6082 | Japanese Industrial Standard designation |

| AA (Aluminium Association) | 6082 | Registered number in Aluminium Association (USA) |

| GB (China) | 6061A | Closest equivalent used in Chinese standards |

Dimension & Weight Chart (Selected common sizes)

Below is a representative chart showing outside diameter, wall thickness, inside diameter, cross-sectional area of metal and calculated weight per metre (kg/m). Values are calculated using density = 7.93 g/cm³ and are for guidance — use actual MTC values for procurement & engineering.

| Section Type | Size (mm) | Thickness (mm) | Weight (kg/m) | Section Modulus (cm³) | Moment of Inertia (cm⁴) |

|---|---|---|---|---|---|

| Equal Angles (Aluminium 6082) | |||||

| Angle | 20 × 20 | 3 | 0.32 | 0.31 | 0.62 |

| Angle | 25 × 25 | 3 | 0.40 | 0.48 | 0.96 |

| Angle | 40 × 40 | 4 | 0.85 | 1.38 | 2.75 |

| Angle | 50 × 50 | 5 | 1.32 | 2.35 | 4.70 |

| Angle | 75 × 75 | 6 | 2.40 | 5.60 | 11.2 |

| Angle | 100 × 100 | 8 | 4.25 | 10.80 | 21.6 |

| Unequal Angles (Aluminium 6082) | |||||

| Angle | 50 × 25 | 4 | 0.90 | 1.15 | 2.30 |

| Angle | 75 × 50 | 5 | 1.70 | 2.75 | 5.50 |

| Angle | 100 × 50 | 6 | 2.55 | 4.85 | 9.70 |

| Channels (Aluminium 6082) | |||||

| Channel | 25 × 12 × 3 | 3 | 0.42 | 0.38 | 0.75 |

| Channel | 50 × 25 × 4 | 4 | 0.88 | 1.30 | 2.60 |

| Channel | 75 × 40 × 5 | 5 | 1.68 | 3.05 | 6.10 |

| Channel | 100 × 50 × 6 | 6 | 2.60 | 5.60 | 11.2 |

| Channel | 150 × 75 × 8 | 8 | 4.90 | 12.40 | 24.8 |

Types Of Aluminium 6082 Angal channel

Stainless Steel Angal & channel

Monel 400 Angal & channel

Inconel 600 Angal & channel

Aluminium Bronze Angal & channel

Super Duplex Angal & channel

Duplex Angal & channel

Nickel Angal & channel

Monel K500 Angal & channel

Frequently Asked Questions (FAQ)

What are the typical applications for Aluminium 6082 angles and channels?

Aluminium 6082 angles & channels are widely used in structural and general engineering applications such as frames, trusses, transport components, architectural profiles, marine fittings, scaffolding, and lightweight structural assemblies where a high strength-to-weight ratio is required.

Which tempers of 6082 are commonly available for angles and channels?

The most common tempers are T6 and T651 for high-strength structural uses. T4 and T5 tempers are offered when improved formability is needed before final aging. Temper selection depends on the balance required between formability and strength.

Is Aluminium 6082 weldable?

Yes — 6082 is weldable by common processes such as TIG and MIG. Post-weld strength may be lower than parent material in heat-treatable tempers, so designers often consider local reinforcement or re-heat treatment if full strength recovery is required.

How does 6082 compare to 6061?

Both are 6xxx-series Al–Mg–Si alloys, but 6082 generally offers higher mechanical strength (especially in T6) and improved fatigue resistance compared with 6061. 6061 is slightly more common in some markets and may offer better machinability in certain conditions. Choice depends on application requirements.

Can Aluminium 6082 be anodized and painted?

Yes. Aluminium 6082 accepts anodizing and powder coating well. Anodizing enhances surface hardness and corrosion resistance; powder coating provides durable color and additional protection. Surface preparation and pretreatment affect final appearance and performance.

Angle Channels Supplier

Mumbai, Delhi, Kolkata, Chennai, Bengaluru, Hyderabad, Ahmadabad, Pune, Surat, Jaipur, Kanpur, Lucknow, Nagpur, Ghaziabad, Indore, Coimbatore, Kochi, Patna, Kozhikode, Thrissur, Vadodara, Agra, Malappuram, Thiruvananthapuram, Kannur, Ludhiana, Nashik, Noida, Madrid, Sharjah, Moscow, Hong Kong, Lagos, Montreal, Bogota, Los Angeles, New Delhi, Jeddah, Chennai, Kanpur, Edmonton, Istanbul, Bhopal, Calgary, Ulsan, Rio de Janeiro, Colombo, Cairo, Ludhiana, Indore, Thane, Dubai, Seoul, Santiago, Kuwait City, Dammam, Tehran, Busan, Rajkot, Nagpur, La Victoria, Bangkok, Granada, Lahore, Manama

Angle Channels Exporter

Aluminium 6082 Angle Channel exporter South Korea, Aluminium 6082 Angle Channel exporter in South Africa, Aluminium 6082 Angle Channel exporter in Sri Lanka, Aluminium 6082 Angle Channel exporter in Syria, Aluminium 6082 Angle Channel exporter in Taiwan, Aluminium 6082 Angle Channel exporter in Tanzania, Aluminium 6082 Angle Channel exporter in Tajikistan, Aluminium 6082 Angle Channel exporter in Thailand, Aluminium 6082 Angle Channel exporter in Turkey, Aluminium 6082 Angle Channel exporter in Turkmenistan, Aluminium 6082 Angle Channel exporter in Ukraine, Aluminium 6082 Angle Channel exporter in United Kingdom, Aluminium 6082 Angle Channel exporter in United Arab Emirates (UAE), Aluminium 6082 Angle Channel exporter in Uzbekistan, Aluminium 6082 Angle Channel exporter in Vietnam, Aluminium 6082 Angle Channel exporter in Yemen, Aluminium 6082 Angle Channel exporter in France, Aluminium 6082 Angle Channel exporter in Germany, Aluminium 6082 Angle Channel exporter in Greece, Aluminium 6082 Angle Channel exporter in Oman, Aluminium 6082 Angle Channel exporter in Colombia, Aluminium 6082 Angle Channel exporter in Portugal, Aluminium 6082 Angle Channel exporter in Japan, Aluminium 6082 Angle Channel exporter in Lithuania, Aluminium 6082 Angle Channel exporter in Macau, Aluminium 6082 Angle Channel exporter in Mongolia, Aluminium 6082 Angle Channel exporter in Qatar, Aluminium 6082 Angle Channel exporter in Ireland, Aluminium 6082 Angle Channel exporter in Malaysia, Aluminium 6082 Angle Channel exporter in Bangladesh, Aluminium 6082 Angle Channel exporter in United Kingdom, Aluminium 6082 Angle Channel exporter in Russia, Aluminium 6082 Angle Channel exporter in Iran, Aluminium 6082 Angle Channel exporter in Vietnam, Aluminium 6082 Angle Channel exporter in Jordan, Aluminium 6082 Angle Channel exporter in Yemen, Aluminium 6082 Angle Channel exporter in South Africa, Aluminium 6082 Angle Channel exporter in Singapore, Aluminium 6082 Angle Channel exporter in Sri Lanka, Aluminium 6082 Angle Channel exporter in Thailand, Aluminium 6082 Angle Channel exporter in Bulgaria, Aluminium 6082 Angle Channel exporter in Poland, Aluminium 6082 Angle Channel exporter in Denmark, Aluminium 6082 Angle Channel exporter in Nigeria, Aluminium 6082 Angle Channel exporter in Gambia, Aluminium 6082 Angle Channel exporter in Indonesia, Aluminium 6082 Angle Channel exporter in Finland, Aluminium 6082 Angle Channel exporter in Argentina, Aluminium 6082 Angle Channel exporter in Chile, Aluminium 6082 Angle Channel exporter in Spain, Aluminium 6082 Angle Channel exporter in Peru, Aluminium 6082 Angle Channel exporter in Kuwait, Aluminium 6082 Angle Channel exporter in India, Aluminium 6082 Angle Channel exporter in Saudi Arabia, Aluminium 6082 Angle Channel exporter in Slovakia, Aluminium 6082 Angle Channel exporter in Slovenia, Aluminium 6082 Angle Channel exporter in Spain, Aluminium 6082 Angle Channel exporter in Sweden, Aluminium 6082 Angle Channel exporter in Switzerland, Aluminium 6082 Angle Channel exporter in Singapore

People Also Search For

SS Sheets Supplier India, SS Coils Supplier India, SS 304 coil price list, SS 304 cold rolled coil distributors, SS 304 profile dealers, SS 304 circle price list, SS 304 coil exporter in mumbai, ss 304 coil Supplier in India, SS 304 coil exporter in india, SS 304 coil-circle exporter in mumbai, ss 304 blank suppliers, SS 304 coils price, ss 304 circle price list, astm a240 ss 304 circles exporter, ss 304 shim coils, SS 304 coil supplier in mumbai, SS Plates Supplier India, , ss 304 coil cheap price, high quality ss 304 coils stockholder in mumbai india.