Aluminium 7075 Angle Channel Manufacturers in India, Aluminium 7075 Angle Channels Price, SS 2062 Price per kg, Aluminium 7075 Angle Channel 2062 suppliers, Aluminium 7075 Angle Channels Price, Aluminium 7075 Angle Channel Suppliers in UAE, Aluminium 7075 Angle Channel Suppliers UK, Aluminium 7075 Angle Channel Suppliers in Saudi Arabia, Aluminium 7075 Angle Channel Suppliers in Qatar, Aluminium 7075 Angle Channel Suppliers Australia.

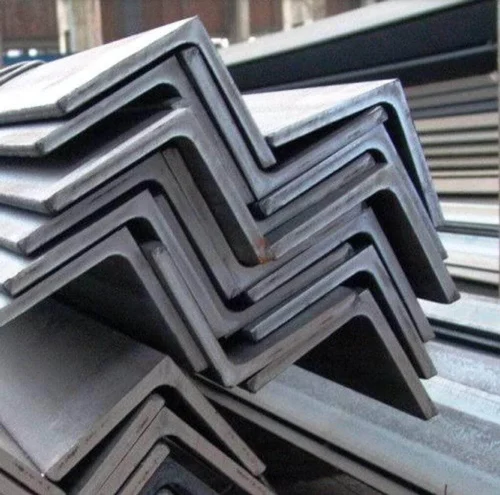

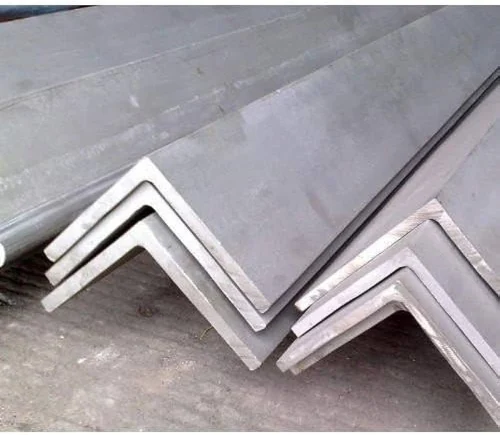

Aluminium 7075 is one of the highest strength aluminium alloys, primarily alloyed with zinc, magnesium, and copper. It offers superior mechanical properties compared to most other aluminium grades, making it ideal for applications where high strength-to-weight ratio is critical. This alloy retains good toughness and machinability even under heavy loads. The 7075-T6 and 7075-T651 tempers are most commonly used for structural and aerospace applications.

7075 aluminium angles and channels are known for their excellent fatigue resistance, allowing them to withstand cyclic stresses and dynamic loads effectively. The combination of low density and high tensile strength provides outstanding performance in high-stress environments. These extrusions are widely used in industries where lightweight materials are essential without compromising strength and stability.

The alloy’s chemical composition includes zinc as the primary alloying element, which contributes to its strength, while magnesium and copper enhance its hardness and stress-corrosion resistance. However, 7075 aluminium has lower corrosion resistance compared to softer grades like 6061 or 5052, so anodizing or coating is recommended for marine or outdoor use. It also exhibits good dimensional stability during machining and fabrication processes.

Aluminium 7075 Angle & Channel products are available in various dimensions, thicknesses, and lengths to suit custom design requirements. They are often supplied in T6 or T651 tempers, ensuring optimal balance between hardness and ductility. The profiles are suitable for applications requiring precision structural components such as aircraft fittings, defense systems, and mechanical frames.

Typical uses of Aluminium 7075 Angle & Channel include aerospace structures, sports equipment, high-performance automotive parts, and marine engineering components. It is especially valued in environments where mechanical loads are high, but overall weight must be minimized. This alloy is also used in molds, tooling jigs, and components requiring both stiffness and reliability.

Aluminium 7075 exhibits excellent machinability, though slightly reduced compared to softer alloys. Proper cutting tools and lubrication should be used to achieve a smooth finish. The material responds well to heat treatment, enabling significant enhancement of its mechanical properties. Welding is not generally recommended due to potential strength reduction, but it can be joined using fasteners or bonding methods.

The key advantages of Aluminium 7075 Angle & Channel are its superior strength, lightweight characteristics, and ability to maintain integrity under extreme mechanical stress. However, it should be protected against corrosion for long-term performance. Its unique balance of performance and durability makes it one of the most sought-after aluminium alloys for demanding engineering and structural applications worldwide.

Specification Table

| Property | Details |

|---|---|

| Standard Designation | Aluminium Alloy 7075 / UNS A97075 / AA7075 |

| Available Forms | Angle, Channel, Flat Bar, Plate, Sheet, Round Bar, Extrusions |

| Temper Designations | T6, T651, T6511, T73 |

| Manufacturing Process | Extruded, Rolled, or Machined from Forged Stock |

| Standards | ASTM B209, ASTM B221, AMS 4045, AMS 4154 |

| Density | 2.81 g/cm³ (0.1015 lb/in³) |

| Melting Point | 477 – 635°C (890 – 1175°F) |

| Modulus of Elasticity | 71.7 GPa (10.4 × 10³ ksi) |

| Thermal Conductivity | 130 W/m·K at 25°C |

| Electrical Conductivity | 33% IACS |

| Corrosion Resistance | Moderate (Requires Protective Coating for Harsh Environments) |

| Machinability | Good (Comparable to Alloy 2014 and 2024) |

| Weldability | Fair to Poor – Mechanical Fastening Recommended |

| Typical Applications | Aerospace Components, Defense Equipment, Automotive Parts, Molds, Jigs, Fixtures, Sports Equipment |

Chemical Composition (Typical ranges for SSIS)

Note: Values are typical ranges. Final composition will be confirmed on MTC provided per lot.

| Element | Percentage (%) |

|---|---|

| Zinc (Zn) | 5.1 – 6.1 |

| Magnesium (Mg) | 2.1 – 2.9 |

| Copper (Cu) | 1.2 – 2.0 |

| Chromium (Cr) | 0.18 – 0.28 |

| Iron (Fe) | ≤ 0.50 |

| Silicon (Si) | ≤ 0.40 |

| Manganese (Mn) | ≤ 0.30 |

| Titanium (Ti) | ≤ 0.20 |

| Other Elements (Each) | ≤ 0.05 |

| Other Elements (Total) | ≤ 0.15 |

| Aluminium (Al) | Balance |

Mechanical Properties (Typical)

| Property | Value (Typical) | Condition / Temper |

|---|---|---|

| Tensile Strength | 510 – 570 MPa (74,000 – 83,000 psi) | T6 / T651 |

| Yield Strength (0.2% Proof) | 430 – 505 MPa (63,000 – 73,000 psi) | T6 / T651 |

| Elongation at Break | 5 – 11% | T6 / T651 |

| Hardness (Brinell) | 150 HB | T6 / T651 |

| Fatigue Strength | 160 MPa (23,000 psi) | Reversed Stress, 500×10⁶ cycles |

| Shear Strength | 330 MPa (48,000 psi) | T6 / T651 |

| Elastic Modulus | 71.7 GPa (10.4 × 10³ ksi) | — |

| Poisson’s Ratio | 0.33 | — |

| Impact Strength (Charpy V-Notch) | 20 J | T6 |

| Machinability Rating | Good (Comparable to Alloy 2014) | — |

Equivalent Grades

| Standard | Equivalent Grade | Description |

|---|---|---|

| UNS | A97075 | Unified Numbering System designation for Aluminium Alloy 7075 |

| AA (Aluminium Association) | 7075 | Standard Aluminium Association grade number |

| ASTM | B209, B221 | Standards covering Aluminium 7075 sheets, plates, bars, and extrusions |

| AMS | 4045, 4049, 4154 | Aerospace Material Specifications for high-strength Aluminium 7075 products |

| ISO | AlZn5.5MgCu | International standard alloy designation for 7075 aluminium |

| EN | EN AW-7075 / AlZn5.5MgCu | European equivalent designation for Aluminium 7075 |

| JIS (Japan) | 7075 | Japanese Industrial Standard for Aluminium Alloy 7075 |

| BS (UK) | 2L95 / 2L97 | British Standard equivalents for high-strength aluminium alloy 7075 |

Dimension & Weight Chart (Selected common sizes)

Below is a representative chart showing outside diameter, wall thickness, inside diameter, cross-sectional area of metal and calculated weight per metre (kg/m). Values are calculated using density = 7.93 g/cm³ and are for guidance — use actual MTC values for procurement & engineering.

| Section Type | Size (mm) | Thickness (mm) | Weight (kg/m) | Approx. Weight (lb/ft) |

|---|---|---|---|---|

| Equal Angle | 20 × 20 | 3 | 0.33 | 0.22 |

| 25 × 25 | 3 | 0.42 | 0.28 | |

| 40 × 40 | 4 | 0.85 | 0.57 | |

| 50 × 50 | 5 | 1.33 | 0.89 | |

| 65 × 65 | 6 | 2.10 | 1.41 | |

| 75 × 75 | 6 | 2.45 | 1.65 | |

| Unequal Angle | 40 × 20 | 3 | 0.55 | 0.37 |

| 50 × 25 | 4 | 0.90 | 0.61 | |

| 65 × 40 | 5 | 1.45 | 0.97 | |

| 75 × 50 | 6 | 2.05 | 1.38 | |

| Channel | 25 × 12 | 3 | 0.42 | 0.28 |

| 40 × 20 | 4 | 0.80 | 0.54 | |

| 50 × 25 | 5 | 1.20 | 0.81 | |

| 65 × 30 | 5 | 1.55 | 1.04 | |

| 75 × 40 | 6 | 2.25 | 1.51 | |

| 100 × 50 | 6 | 2.95 | 1.98 |

Types Of Aluminium 7075 Angal channel

Stainless Steel Angal & channel

Monel 400 Angal & channel

Inconel 600 Angal & channel

Aluminium Bronze Angal & channel

Super Duplex Angal & channel

Duplex Angal & channel

Nickel Angal & channel

Monel K500 Angal & channel

Frequently Asked Questions (FAQ)

What is Aluminium 7075 and why is it used for angles and channels?

Aluminium 7075 is a high-strength, heat-treatable aluminium alloy primarily strengthened with zinc and magnesium. It is used for angles and channels where a high strength-to-weight ratio and good fatigue performance are required — common in aerospace, high-performance engineering, and structural components.

What are the typical mechanical properties of 7075 angles and channels?

7075 offers among the highest strength levels of commercial aluminium alloys when properly heat treated. It combines high tensile and yield strength with good fatigue resistance, making it suitable for high-stress structural applications. Exact properties depend on temper (T6, T651, etc.) and product form.

What is the chemical composition of Aluminium 7075?

7075 is an aluminium–zinc–magnesium–copper alloy. Zinc is the principal alloying element with smaller amounts of magnesium and copper. Trace elements and exact percentages vary by specification and producer; consult the material datasheet for precise composition limits.

Can Aluminium 7075 be welded?

Conventional fusion welding is generally not recommended because 7075 is prone to cracking and strength loss in the weld zone. If welding is required, specialized methods (such as friction stir welding) and post-weld heat treatment may be used by experienced fabricators; otherwise mechanical fastening or adhesive bonding is preferred.

How is Aluminium 7075 for machining and forming?

7075 machines well compared with many other high-strength alloys but is harder on tooling than softer commercial alloys. It is less ductile than typical structural alloys, so cold forming is limited — forming operations are typically done before final heat treatment or use designs that minimize tight bends.

Angle Channels Supplier

Mumbai, Delhi, Kolkata, Chennai, Bengaluru, Hyderabad, Ahmadabad, Pune, Surat, Jaipur, Kanpur, Lucknow, Nagpur, Ghaziabad, Indore, Coimbatore, Kochi, Patna, Kozhikode, Thrissur, Vadodara, Agra, Malappuram, Thiruvananthapuram, Kannur, Ludhiana, Nashik, Noida, Madrid, Sharjah, Moscow, Hong Kong, Lagos, Montreal, Bogota, Los Angeles, New Delhi, Jeddah, Chennai, Kanpur, Edmonton, Istanbul, Bhopal, Calgary, Ulsan, Rio de Janeiro, Colombo, Cairo, Ludhiana, Indore, Thane, Dubai, Seoul, Santiago, Kuwait City, Dammam, Tehran, Busan, Rajkot, Nagpur, La Victoria, Bangkok, Granada, Lahore, Manama

Angle Channels Exporter

Aluminium 7075 Angle Channel exporter South Korea, Aluminium 7075 Angle Channel exporter in South Africa, Aluminium 7075 Angle Channel exporter in Sri Lanka, Aluminium 7075 Angle Channel exporter in Syria, Aluminium 7075 Angle Channel exporter in Taiwan, Aluminium 7075 Angle Channel exporter in Tanzania, Aluminium 7075 Angle Channel exporter in Tajikistan, Aluminium 7075 Angle Channel exporter in Thailand, Aluminium 7075 Angle Channel exporter in Turkey, Aluminium 7075 Angle Channel exporter in Turkmenistan, Aluminium 7075 Angle Channel exporter in Ukraine, Aluminium 7075 Angle Channel exporter in United Kingdom, Aluminium 7075 Angle Channel exporter in United Arab Emirates (UAE), Aluminium 7075 Angle Channel exporter in Uzbekistan, Aluminium 7075 Angle Channel exporter in Vietnam, Aluminium 7075 Angle Channel exporter in Yemen, Aluminium 7075 Angle Channel exporter in France, Aluminium 7075 Angle Channel exporter in Germany, Aluminium 7075 Angle Channel exporter in Greece, Aluminium 7075 Angle Channel exporter in Oman, Aluminium 7075 Angle Channel exporter in Colombia, Aluminium 7075 Angle Channel exporter in Portugal, Aluminium 7075 Angle Channel exporter in Japan, Aluminium 7075 Angle Channel exporter in Lithuania, Aluminium 7075 Angle Channel exporter in Macau, Aluminium 7075 Angle Channel exporter in Mongolia, Aluminium 7075 Angle Channel exporter in Qatar, Aluminium 7075 Angle Channel exporter in Ireland, Aluminium 7075 Angle Channel exporter in Malaysia, Aluminium 7075 Angle Channel exporter in Bangladesh, Aluminium 7075 Angle Channel exporter in United Kingdom, Aluminium 7075 Angle Channel exporter in Russia, Aluminium 7075 Angle Channel exporter in Iran, Aluminium 7075 Angle Channel exporter in Vietnam, Aluminium 7075 Angle Channel exporter in Jordan, Aluminium 7075 Angle Channel exporter in Yemen, Aluminium 7075 Angle Channel exporter in South Africa, Aluminium 7075 Angle Channel exporter in Singapore, Aluminium 7075 Angle Channel exporter in Sri Lanka, Aluminium 7075 Angle Channel exporter in Thailand, Aluminium 7075 Angle Channel exporter in Bulgaria, Aluminium 7075 Angle Channel exporter in Poland, Aluminium 7075 Angle Channel exporter in Denmark, Aluminium 7075 Angle Channel exporter in Nigeria, Aluminium 7075 Angle Channel exporter in Gambia, Aluminium 7075 Angle Channel exporter in Indonesia, Aluminium 7075 Angle Channel exporter in Finland, Aluminium 7075 Angle Channel exporter in Argentina, Aluminium 7075 Angle Channel exporter in Chile, Aluminium 7075 Angle Channel exporter in Spain, Aluminium 7075 Angle Channel exporter in Peru, Aluminium 7075 Angle Channel exporter in Kuwait, Aluminium 7075 Angle Channel exporter in India, Aluminium 7075 Angle Channel exporter in Saudi Arabia, Aluminium 7075 Angle Channel exporter in Slovakia, Aluminium 7075 Angle Channel exporter in Slovenia, Aluminium 7075 Angle Channel exporter in Spain, Aluminium 7075 Angle Channel exporter in Sweden, Aluminium 7075 Angle Channel exporter in Switzerland, Aluminium 7075 Angle Channel exporter in Singapore

People Also Search For

SS Sheets Supplier India, SS Coils Supplier India, SS 304 coil price list, SS 304 cold rolled coil distributors, SS 304 profile dealers, SS 304 circle price list, SS 304 coil exporter in mumbai, ss 304 coil Supplier in India, SS 304 coil exporter in india, SS 304 coil-circle exporter in mumbai, ss 304 blank suppliers, SS 304 coils price, ss 304 circle price list, astm a240 ss 304 circles exporter, ss 304 shim coils, SS 304 coil supplier in mumbai, SS Plates Supplier India, , ss 304 coil cheap price, high quality ss 304 coils stockholder in mumbai india.