ETP Copper (C11000) Angle Channel Manufacturers in India, ETP Copper (C11000) Angle Channels Price, SS 2062 Price per kg, ETP Copper (C11000) Angle Channel 2062 suppliers, ETP Copper (C11000) Angle Channels Price, ETP Copper (C11000) Angle Channel Suppliers in UAE, ETP Copper (C11000) Angle Channel Suppliers UK, ETP Copper (C11000) Angle Channel Suppliers in Saudi Arabia, ETP Copper (C11000) Angle Channel Suppliers in Qatar, ETP Copper (C11000) Angle Channel Suppliers Australia.

ETP Copper (C11000) Angle & Channel is a high-quality product made from Electrolytic Tough Pitch copper, known for its superior electrical and thermal conductivity. This copper grade contains a minimum of 99.9% pure copper, ensuring consistent performance in conductive and mechanical applications. Its purity and controlled oxygen content provide excellent ductility and formability, making it suitable for both structural and electrical components. The material is widely used in industries that require reliable conductivity and durability. C11000 copper is easily fabricated by standard forming, machining, and joining methods. Its versatility makes it one of the most popular copper grades in commercial use today.

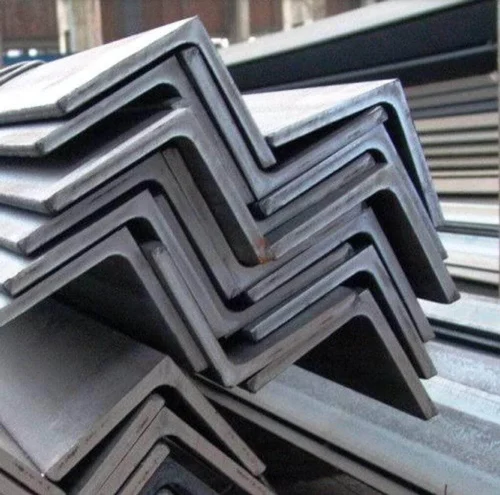

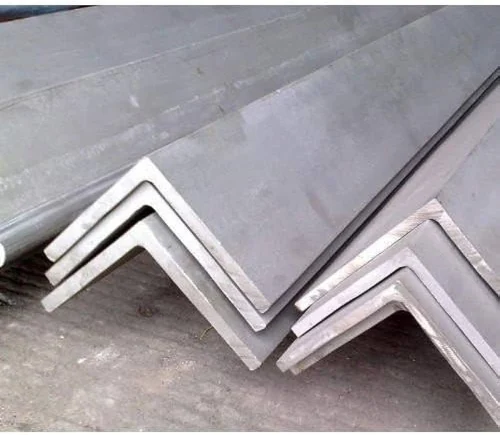

ETP Copper Angles are commonly used in electrical systems, architectural frameworks, and decorative metalwork due to their excellent conductivity and visual appeal. These angle sections are available in various leg lengths and thicknesses, making them suitable for lightweight to medium-duty structures. Their high strength and corrosion resistance ensure long-lasting performance even in demanding environments. With its natural reddish appearance, ETP Copper also provides aesthetic value in modern architectural and design applications. The material can be easily polished or coated depending on the end-use requirements. Its smooth surface and uniform composition allow for high-quality finishes and reliable welding or brazing.

ETP Copper Channels are U- or C-shaped profiles that provide both mechanical strength and efficient current-carrying capacity. They are used in busbar systems, switchgear, electrical enclosures, and other components where conductivity and rigidity are essential. These channels can be customized in width, thickness, and length to meet specific electrical or structural needs. Their uniform cross-section ensures even current distribution and minimal resistance loss. The material’s excellent machinability allows easy drilling and fabrication during installation. As a result, ETP Copper channels are a preferred choice for both industrial and architectural applications.

The key benefit of C11000 copper is its exceptional conductivity—approximately 100% IACS (International Annealed Copper Standard)—making it ideal for power transmission and grounding systems. Its thermal conductivity also enables efficient heat dissipation, making it valuable in HVAC, transformers, and electronic systems. The material resists oxidation in air and forms a stable protective layer over time, ensuring long-term corrosion resistance. ETP Copper performs consistently under both high and low temperatures, providing reliability across varied industrial conditions. Its combination of conductivity, strength, and machinability sets it apart from other metals like aluminum or brass.

In mechanical terms, ETP Copper (C11000) provides excellent strength-to-weight ratio with a tensile strength range of approximately 200–400 MPa, depending on temper. It exhibits high ductility, allowing bending and shaping without cracking or failure. The material can be supplied in different tempers such as soft annealed, half-hard, or hard drawn, depending on required mechanical and electrical characteristics. For applications involving frequent vibration or movement, the flexibility of ETP copper angles and channels ensures long service life. Its high density and modulus of elasticity provide structural integrity for precision components. These properties make it suitable for manufacturing connectors, electrical contacts, and heat exchanger plates.

Architectural and decorative applications also benefit from the unique properties of ETP Copper. The metal develops a natural patina over time that protects it from corrosion while giving an attractive aged look. Copper channels and angles are used in facades, window frames, handrails, and artistic installations for both their strength and beauty. Their warm metallic luster complements a wide range of design styles from classic to contemporary. The material’s eco-friendliness, being fully recyclable without loss of performance, adds sustainability value to architectural projects. Designers and engineers often choose C11000 for its balance of functionality and aesthetic appeal.

Overall, ETP Copper (C11000) Angles and Channels combine high conductivity, formability, and durability to meet diverse industrial requirements. Whether used in power distribution, machinery components, or decorative applications, these copper profiles deliver unmatched performance and reliability. They are available in a variety of sizes and finishes to suit custom specifications. The material’s easy fabrication and joining capabilities further enhance its adaptability in manufacturing. With a proven track record in electrical, thermal, and structural roles, C11000 copper remains a preferred choice across multiple sectors. Its excellent balance of properties continues to make it an essential engineering material worldwide.

Specification Table

| Property | Specification / Details |

|---|---|

| Product Name | ETP Copper (C11000) Angle & Channel |

| Material Grade | C11000 - Electrolytic Tough Pitch Copper (Cu-ETP) |

| Standard | ASTM B152 / B187 / B224, BS EN 1652, ISO 1634 |

| Chemical Composition | Cu ≥ 99.90%, O ≤ 0.04% |

| Density | 8.9 g/cm³ |

| Electrical Conductivity | ≥ 100% IACS (58 MS/m) |

| Thermal Conductivity | Approx. 390 W/m·K |

| Tensile Strength | 200 – 400 MPa (depending on temper) |

| Elongation | 30 – 45% |

| Hardness | 40 – 110 HV (varies with temper) |

| Melting Point | 1083°C (1981°F) |

| Available Forms | Angle (L-section), Channel (U/C-section) |

| Surface Finish | Mill Finish, Polished, Bright, Tinned |

| Manufacturing Process | Hot Rolled / Cold Rolled / Extruded |

| Applications | Busbars, Electrical Conductors, Frames, Decorative Structures, HVAC Systems |

| Country of Origin | Made in India |

Chemical Composition (Typical ranges for SSIS)

Note: Values are typical ranges. Final composition will be confirmed on MTC provided per lot.

| Element | Symbol | Percentage (%) |

|---|---|---|

| Copper | Cu | ≥ 99.90% |

| Oxygen | O | 0.02 – 0.04% |

| Lead | Pb | ≤ 0.005% |

| Iron | Fe | ≤ 0.005% |

| Nickel | Ni | ≤ 0.005% |

| Zinc | Zn | ≤ 0.003% |

| Others (Total) | - | ≤ 0.03% |

Mechanical Properties (Typical)

| Property | Condition / Temper | Typical Value | Units |

|---|---|---|---|

| Tensile Strength | Annealed (Soft) | 200 – 250 | MPa |

| Tensile Strength | Half Hard | 250 – 300 | MPa |

| Tensile Strength | Hard (Cold Worked) | 300 – 400 | MPa |

| Yield Strength (0.2% offset) | Annealed | 50 – 100 | MPa |

| Elongation | Annealed | 30 – 45 | % |

| Hardness | Annealed | 40 – 60 | HV |

| Hardness | Hard (Cold Worked) | 80 – 110 | HV |

| Modulus of Elasticity | All Tempers | 110 – 125 | GPa |

| Density | All Tempers | 8.9 | g/cm³ |

| Melting Point | — | 1083 | °C |

Equivalent Grades

| Standard | Grade Designation | Description / Notes |

|---|---|---|

| UNS | C11000 | Electrolytic Tough Pitch (ETP) Copper |

| ASTM | B152 / B187 | Standard specification for copper sheet, strip, bar, and shapes |

| BS (British Standard) | CW004A | BS EN 1652 designation for Cu-ETP (high conductivity copper) |

| EN | Cu-ETP | European equivalent grade for high-conductivity electrolytic copper |

| JIS | C1100 | Japanese Industrial Standard equivalent for electrolytic copper |

| DIN | Cu-ETP / 2.0060 | German designation for electrolytic tough pitch copper |

| ISO | Cu-ETP | International standard for high-conductivity copper |

| AFNOR (France) | CUA1 | French equivalent grade for ETP Copper |

Dimension & Weight Chart (Selected common sizes)

Below is a representative chart showing outside diameter, wall thickness, inside diameter, cross-sectional area of metal and calculated weight per metre (kg/m). Values are calculated using density = 7.93 g/cm³ and are for guidance — use actual MTC values for procurement & engineering.

| Size (Thickness × Leg × Leg) | Approx. Weight per Meter (kg/m) | Cross-Sectional Area (mm²) | Typical Length (m) |

|---|---|---|---|

| 3 mm × 20 mm × 20 mm | 0.96 | 108 | 3 / 6 |

| 4 mm × 25 mm × 25 mm | 1.55 | 174 | 3 / 6 |

| 5 mm × 30 mm × 30 mm | 2.23 | 250 | 3 / 6 |

| 6 mm × 40 mm × 40 mm | 3.82 | 428 | 3 / 6 |

| 8 mm × 50 mm × 50 mm | 6.36 | 714 | 3 / 6 |

| 10 mm × 65 mm × 65 mm | 10.35 | 1163 | 3 / 6 |

| 12 mm × 75 mm × 75 mm | 14.90 | 1675 | 3 / 6 |

| 12 mm × 100 mm × 100 mm | 19.80 | 2225 | 3 / 6 |

| Channel 6 mm × 50 mm × 25 mm | 4.25 | 477 | 3 / 6 |

| Channel 8 mm × 75 mm × 40 mm | 8.20 | 920 | 3 / 6 |

| Channel 10 mm × 100 mm × 50 mm | 12.85 | 1440 | 3 / 6 |

Types Of ETP copper Angal channel

Stainless Steel Angal & channel

Monel 400 Angal & channel

Inconel 600 Angal & channel

Hastelloy Angal & channel

Super Duplex Angal & channel

Duplex Angal & channel

Nickel Angal & channel

Monel K500 Angal & channel

Frequently Asked Questions (FAQ)

What is ETP Copper (C11000)?

ETP Copper (Electrolytic Tough Pitch Copper), designated as C11000, is a high-purity copper material containing a small amount of oxygen to enhance conductivity. It offers excellent electrical and thermal conductivity, good corrosion resistance, and ease of fabrication.

What are the key applications of ETP Copper Angles and Channels?

ETP Copper Angles and Channels are widely used in electrical busbars, power distribution panels, switchgear, grounding systems, and architectural elements due to their high conductivity and formability.

How does ETP Copper differ from Oxygen-Free Copper?

ETP Copper contains about 0.02–0.04% oxygen, providing excellent conductivity (over 101% IACS). Oxygen-Free Copper, however, is refined to remove oxygen completely, which offers better performance for vacuum or high-temperature applications.

What are the available sizes and forms of ETP Copper (C11000) Angle & Channel?

ETP Copper Angles and Channels are available in a wide range of sizes and thicknesses, typically from 3 mm to 12 mm thick, and leg sizes from 20 mm to 100 mm. Custom dimensions and lengths are also available upon request.

Is ETP Copper (C11000) suitable for outdoor or marine applications?

Yes, ETP Copper (C11000) performs well in most atmospheric and mild marine conditions. However, for extreme corrosion resistance, it is recommended to use copper alloys like Phosphor Bronze or Nickel Copper alloys.

Can ETP Copper Angles and Channels be welded or brazed?

ETP Copper can be easily soldered, brazed, and welded using proper techniques. However, care should be taken to avoid hydrogen embrittlement when welding in reducing atmospheres.

Angle Channels Supplier

Mumbai, Delhi, Kolkata, Chennai, Bengaluru, Hyderabad, Ahmadabad, Pune, Surat, Jaipur, Kanpur, Lucknow, Nagpur, Ghaziabad, Indore, Coimbatore, Kochi, Patna, Kozhikode, Thrissur, Vadodara, Agra, Malappuram, Thiruvananthapuram, Kannur, Ludhiana, Nashik, Noida, Madrid, Sharjah, Moscow, Hong Kong, Lagos, Montreal, Bogota, Los Angeles, New Delhi, Jeddah, Chennai, Kanpur, Edmonton, Istanbul, Bhopal, Calgary, Ulsan, Rio de Janeiro, Colombo, Cairo, Ludhiana, Indore, Thane, Dubai, Seoul, Santiago, Kuwait City, Dammam, Tehran, Busan, Rajkot, Nagpur, La Victoria, Bangkok, Granada, Lahore, Manama

Angle Channels Exporter

ETP Copper (C11000) Angle Channel exporter South Korea, ETP Copper (C11000) Angle Channel exporter in South Africa, ETP Copper (C11000) Angle Channel exporter in Sri Lanka, ETP Copper (C11000) Angle Channel exporter in Syria, ETP Copper (C11000) Angle Channel exporter in Taiwan, ETP Copper (C11000) Angle Channel exporter in Tanzania, ETP Copper (C11000) Angle Channel exporter in Tajikistan, ETP Copper (C11000) Angle Channel exporter in Thailand, ETP Copper (C11000) Angle Channel exporter in Turkey, ETP Copper (C11000) Angle Channel exporter in Turkmenistan, ETP Copper (C11000) Angle Channel exporter in Ukraine, ETP Copper (C11000) Angle Channel exporter in United Kingdom, ETP Copper (C11000) Angle Channel exporter in United Arab Emirates (UAE), ETP Copper (C11000) Angle Channel exporter in Uzbekistan, ETP Copper (C11000) Angle Channel exporter in Vietnam, ETP Copper (C11000) Angle Channel exporter in Yemen, ETP Copper (C11000) Angle Channel exporter in France, ETP Copper (C11000) Angle Channel exporter in Germany, ETP Copper (C11000) Angle Channel exporter in Greece, ETP Copper (C11000) Angle Channel exporter in Oman, ETP Copper (C11000) Angle Channel exporter in Colombia, ETP Copper (C11000) Angle Channel exporter in Portugal, ETP Copper (C11000) Angle Channel exporter in Japan, ETP Copper (C11000) Angle Channel exporter in Lithuania, ETP Copper (C11000) Angle Channel exporter in Macau, ETP Copper (C11000) Angle Channel exporter in Mongolia, ETP Copper (C11000) Angle Channel exporter in Qatar, ETP Copper (C11000) Angle Channel exporter in Ireland, ETP Copper (C11000) Angle Channel exporter in Malaysia, ETP Copper (C11000) Angle Channel exporter in Bangladesh, ETP Copper (C11000) Angle Channel exporter in United Kingdom, ETP Copper (C11000) Angle Channel exporter in Russia, ETP Copper (C11000) Angle Channel exporter in Iran, ETP Copper (C11000) Angle Channel exporter in Vietnam, ETP Copper (C11000) Angle Channel exporter in Jordan, ETP Copper (C11000) Angle Channel exporter in Yemen, ETP Copper (C11000) Angle Channel exporter in South Africa, ETP Copper (C11000) Angle Channel exporter in Singapore, ETP Copper (C11000) Angle Channel exporter in Sri Lanka, ETP Copper (C11000) Angle Channel exporter in Thailand, ETP Copper (C11000) Angle Channel exporter in Bulgaria, ETP Copper (C11000) Angle Channel exporter in Poland, ETP Copper (C11000) Angle Channel exporter in Denmark, ETP Copper (C11000) Angle Channel exporter in Nigeria, ETP Copper (C11000) Angle Channel exporter in Gambia, ETP Copper (C11000) Angle Channel exporter in Indonesia, ETP Copper (C11000) Angle Channel exporter in Finland, ETP Copper (C11000) Angle Channel exporter in Argentina, ETP Copper (C11000) Angle Channel exporter in Chile, ETP Copper (C11000) Angle Channel exporter in Spain, ETP Copper (C11000) Angle Channel exporter in Peru, ETP Copper (C11000) Angle Channel exporter in Kuwait, ETP Copper (C11000) Angle Channel exporter in India, ETP Copper (C11000) Angle Channel exporter in Saudi Arabia, ETP Copper (C11000) Angle Channel exporter in Slovakia, ETP Copper (C11000) Angle Channel exporter in Slovenia, ETP Copper (C11000) Angle Channel exporter in Spain, ETP Copper (C11000) Angle Channel exporter in Sweden, ETP Copper (C11000) Angle Channel exporter in Switzerland, ETP Copper (C11000) Angle Channel exporter in Singapore

People Also Search For

ETP Sheets Supplier India, ETP Coils Supplier India, SS 304 coil price list, ETP 304 cold rolled coil distributors, ETP 304 profile dealers, ETP 304 circle price list, ETP 304 coil exporter in mumbai, ss 304 coil Supplier in India, ETP 304 coil exporter in india, ETP 304 coil-circle exporter in mumbai, ss 304 blank suppliers, ETP 304 coils price, ss 304 circle price list, astm a240 ss 304 circles exporter, ss 304 shim coils, ETP 304 coil supplier in mumbai, ETP Plates Supplier India, , ss 304 coil cheap price, high quality ss 304 coils stockholder in mumbai india.