H11 Tool Steel Angle Channel Manufacturers in India, H11 Tool Steel Angle Channels Price, SS 2062 Price per kg, H11 Tool Steel Angle Channel 2062 suppliers, H11 Tool Steel Angle Channels Price, H11 Tool Steel Angle Channel Suppliers in UAE, H11 Tool Steel Angle Channel Suppliers UK, H11 Tool Steel Angle Channel Suppliers in Saudi Arabia, H11 Tool Steel Angle Channel Suppliers in Qatar, H11 Tool Steel Angle Channel Suppliers Australia.

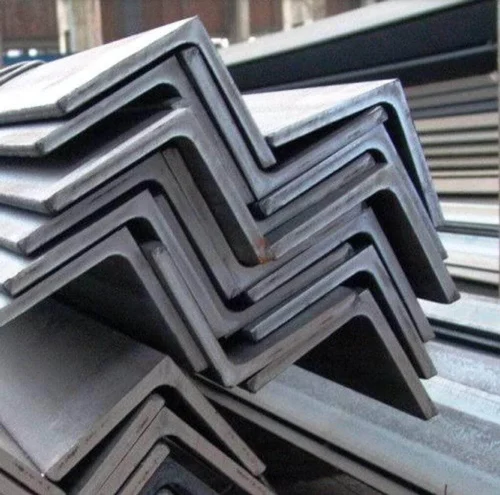

H11 Tool Steel Angle & Channel are high-performance components made from chromium-based hot work tool steel, known for their exceptional toughness and thermal fatigue resistance. These profiles are engineered to maintain strength and hardness even at elevated temperatures, making them ideal for demanding industrial environments. H11 steel is often used in the production of die-casting tools, forging dies, and extrusion dies where superior durability and wear resistance are required. The angles and channels are available in multiple sizes, meeting both standard and custom manufacturing requirements. Their versatility and mechanical stability make them a preferred choice in tool and die-making industries worldwide.

H11 Tool Steel Angles and Channels offer a unique combination of strength, ductility, and high-temperature toughness. They are designed to resist cracking during heating and cooling cycles, a key factor in hot work applications. The material demonstrates good machinability and excellent dimensional stability after heat treatment. Due to its fine grain structure, it ensures consistent mechanical performance and surface finish. Moreover, H11 maintains its hardness up to 425°C (797°F), ensuring long-term performance in heat-exposed operations. Its ability to withstand both thermal and mechanical stress makes it a premium choice for long-lasting tooling components.

Manufacturing H11 Tool Steel Angle & Channel involves precision melting, forging, and forming processes that ensure structural integrity and homogeneity. The steel is typically supplied in an annealed condition for ease of machining and then heat-treated to achieve desired hardness levels. The heat treatment process includes preheating, austenitizing, quenching, and tempering to balance hardness with toughness. Post-treatment, these components can achieve a Rockwell hardness of around 50 HRC, depending on the tempering temperature. Proper heat treatment enhances wear resistance, fatigue strength, and dimensional accuracy, ensuring a longer tool life even in high-load applications.

H11 Tool Steel Angles and Channels are extensively used in industries requiring resistance to thermal fatigue and mechanical wear. They are widely used in the aerospace, automotive, and die-casting sectors for tooling applications such as extrusion dies, forging dies, and die-casting molds. In addition, these components are used in heavy-duty machinery where stability and precision are vital. Their ability to perform under extreme heat and pressure conditions makes them indispensable for hot work operations. The combination of strength, ductility, and resistance to cracking under thermal stress ensures consistent performance across challenging applications.

The primary advantages of H11 Tool Steel Angles and Channels include superior toughness, excellent machinability, and high resistance to softening at elevated temperatures. Their uniform hardness ensures minimal distortion during machining and heat treatment. They also possess excellent resistance to shock and impact loading, reducing the likelihood of tool failure in demanding applications. H11’s fine microstructure allows for excellent polishability and surface quality, making it suitable for precision molds. Furthermore, its wear and abrasion resistance reduce downtime and maintenance costs, improving productivity in manufacturing environments.

H11 Tool Steel offers moderate machinability when supplied in the annealed condition, typically around 200 Brinell hardness. Proper machining parameters and the use of cutting fluids are recommended to achieve smooth and accurate results. Its weldability is fair, provided preheating and post-weld heat treatment procedures are followed to avoid cracking. Grinding and surface finishing are easily performed with appropriate abrasives. This steel’s stability during machining minimizes warping and ensures accurate dimensional control. Thus, H11 Angles and Channels are ideal for precision-engineered components that demand consistency and longevity in service.

Specification Table

| Property | Specification |

|---|---|

| Grade | H11 Tool Steel (AISI H11 / DIN 1.2343 / UNS T20811) |

| Type | Hot Work Tool Steel |

| Product Forms | Angle, Channel, Round Bar, Flat, Square, Block |

| Standard | AISI, ASTM, DIN, EN, JIS |

| Hardness (After Heat Treatment) | 46 - 50 HRC |

| Working Temperature | Up to 425°C (797°F) |

| Condition | Annealed / Pre-Hardened / Heat Treated |

| Surface Finish | Black, Bright, Polished, or as required |

| Manufacturing Process | Hot Rolled / Forged / Machined |

| Applications | Die Casting Dies, Forging Dies, Extrusion Dies, Tool Holders, Aerospace Components |

Chemical Composition (Typical ranges for SSIS)

Note: Values are typical ranges. Final composition will be confirmed on MTC provided per lot.

| Element | Percentage (%) |

|---|---|

| Carbon (C) | 0.35 – 0.45 |

| Chromium (Cr) | 4.75 – 5.50 |

| Molybdenum (Mo) | 1.10 – 1.75 |

| Vanadium (V) | 0.30 – 0.60 |

| Silicon (Si) | 0.80 – 1.20 |

| Manganese (Mn) | 0.20 – 0.50 |

| Phosphorus (P) | ≤ 0.030 |

| Sulphur (S) | ≤ 0.030 |

| Iron (Fe) | Balance |

Mechanical Properties (Typical)

| Property | Value | Condition |

|---|---|---|

| Hardness | 46 – 50 HRC | After Heat Treatment |

| Tensile Strength | ~1860 MPa | Heat Treated |

| Yield Strength | ~1500 MPa | Heat Treated |

| Elongation | ~10 – 15% | Annealed |

| Impact Strength (Charpy V-Notch) | ≥ 20 J | Heat Treated |

| Modulus of Elasticity | ~210 GPa | At Room Temperature |

| Density | 7.80 g/cm³ | At 20°C |

| Thermal Conductivity | 24.5 W/m·K | At 20°C |

| Coefficient of Expansion | 11.1 × 10⁻⁶ /°C | 20–100°C |

Equivalent Grades

| Standard | Equivalent Grade | Country / Region |

|---|---|---|

| AISI / SAE | H11 | United States |

| UNS | T20811 | United States |

| DIN | 1.2343 | Germany |

| Werkstoff | X37CrMoV5-1 | Europe |

| BS (British Standard) | BD3 | United Kingdom |

| JIS | SKD6 | Japan |

| AFNOR | Z38CDV5 | France |

| GOST | 4Kh5MFS | Russia |

Dimension & Weight Chart (Selected common sizes)

Below is a representative chart showing outside diameter, wall thickness, inside diameter, cross-sectional area of metal and calculated weight per metre (kg/m). Values are calculated using density = 7.93 g/cm³ and are for guidance — use actual MTC values for procurement & engineering.

| Size (mm) | Thickness (mm) | Length (m) | Weight (kg/m) | Section Type |

|---|---|---|---|---|

| 25 × 25 | 3 | 6 | 1.10 | Angle |

| 40 × 40 | 4 | 6 | 2.30 | Angle |

| 50 × 50 | 5 | 6 | 3.60 | Angle |

| 65 × 65 | 6 | 6 | 5.40 | Angle |

| 75 × 75 | 6 | 6 | 6.80 | Angle |

| 100 × 50 | 5 | 6 | 4.60 | Channel |

| 125 × 65 | 6 | 6 | 6.80 | Channel |

| 150 × 75 | 6 | 6 | 8.60 | Channel |

| 200 × 100 | 8 | 6 | 13.60 | Channel |

| 250 × 125 | 9 | 6 | 19.20 | Channel |

Types Of H11 Tool Steel Angal channel

Stainless Steel Angal & channel

Monel 400 Angal & channel

Inconel 600 Angal & channel

Aluminium Bronze Angal & channel

Super Duplex Angal & channel

Duplex Angal & channel

Nickel Angal & channel

Monel K500 Angal & channel

Frequently Asked Questions (FAQ)

What is H11 Tool Steel?

H11 Tool Steel is a chromium-based hot work tool steel known for its high toughness, thermal fatigue resistance, and ability to maintain hardness at elevated temperatures. It is commonly used in die-casting, forging, and extrusion tooling applications.

What are the main uses of H11 Tool Steel Angles and Channels?

H11 Tool Steel Angles and Channels are widely used in aerospace, automotive, and heavy industrial sectors for manufacturing dies, molds, and structural components exposed to high thermal and mechanical stress.

What is the hardness of H11 Tool Steel after heat treatment?

After proper heat treatment, H11 Tool Steel typically achieves a hardness level between 46 and 50 HRC, ensuring excellent wear resistance and durability in hot work applications.

Is H11 Tool Steel corrosion resistant?

H11 Tool Steel offers moderate resistance to oxidation and scaling due to its chromium content, but it is not fully stainless. Surface coatings like nitriding or PVD can be applied to improve corrosion and wear resistance.

What standards cover H11 Tool Steel?

H11 Tool Steel conforms to several international standards, including AISI H11, DIN 1.2343, JIS SKD6, and UNS T20811. These ensure consistent quality and performance across global manufacturing industries.

Angle Channels Supplier

Mumbai, Delhi, Kolkata, Chennai, Bengaluru, Hyderabad, Ahmadabad, Pune, Surat, Jaipur, Kanpur, Lucknow, Nagpur, Ghaziabad, Indore, Coimbatore, Kochi, Patna, Kozhikode, Thrissur, Vadodara, Agra, Malappuram, Thiruvananthapuram, Kannur, Ludhiana, Nashik, Noida, Madrid, Sharjah, Moscow, Hong Kong, Lagos, Montreal, Bogota, Los Angeles, New Delhi, Jeddah, Chennai, Kanpur, Edmonton, Istanbul, Bhopal, Calgary, Ulsan, Rio de Janeiro, Colombo, Cairo, Ludhiana, Indore, Thane, Dubai, Seoul, Santiago, Kuwait City, Dammam, Tehran, Busan, Rajkot, Nagpur, La Victoria, Bangkok, Granada, Lahore, Manama

Angle Channels Exporter

H11 Tool Steel Angle Channel exporter South Korea, H11 Tool Steel Angle Channel exporter in South Africa, H11 Tool Steel Angle Channel exporter in Sri Lanka, H11 Tool Steel Angle Channel exporter in Syria, H11 Tool Steel Angle Channel exporter in Taiwan, H11 Tool Steel Angle Channel exporter in Tanzania, H11 Tool Steel Angle Channel exporter in Tajikistan, H11 Tool Steel Angle Channel exporter in Thailand, H11 Tool Steel Angle Channel exporter in Turkey, H11 Tool Steel Angle Channel exporter in Turkmenistan, H11 Tool Steel Angle Channel exporter in Ukraine, H11 Tool Steel Angle Channel exporter in United Kingdom, H11 Tool Steel Angle Channel exporter in United Arab Emirates (UAE), H11 Tool Steel Angle Channel exporter in Uzbekistan, H11 Tool Steel Angle Channel exporter in Vietnam, H11 Tool Steel Angle Channel exporter in Yemen, H11 Tool Steel Angle Channel exporter in France, H11 Tool Steel Angle Channel exporter in Germany, H11 Tool Steel Angle Channel exporter in Greece, H11 Tool Steel Angle Channel exporter in Oman, H11 Tool Steel Angle Channel exporter in Colombia, H11 Tool Steel Angle Channel exporter in Portugal, H11 Tool Steel Angle Channel exporter in Japan, H11 Tool Steel Angle Channel exporter in Lithuania, H11 Tool Steel Angle Channel exporter in Macau, H11 Tool Steel Angle Channel exporter in Mongolia, H11 Tool Steel Angle Channel exporter in Qatar, H11 Tool Steel Angle Channel exporter in Ireland, H11 Tool Steel Angle Channel exporter in Malaysia, H11 Tool Steel Angle Channel exporter in Bangladesh, H11 Tool Steel Angle Channel exporter in United Kingdom, H11 Tool Steel Angle Channel exporter in Russia, H11 Tool Steel Angle Channel exporter in Iran, H11 Tool Steel Angle Channel exporter in Vietnam, H11 Tool Steel Angle Channel exporter in Jordan, H11 Tool Steel Angle Channel exporter in Yemen, H11 Tool Steel Angle Channel exporter in South Africa, H11 Tool Steel Angle Channel exporter in Singapore, H11 Tool Steel Angle Channel exporter in Sri Lanka, H11 Tool Steel Angle Channel exporter in Thailand, H11 Tool Steel Angle Channel exporter in Bulgaria, H11 Tool Steel Angle Channel exporter in Poland, H11 Tool Steel Angle Channel exporter in Denmark, H11 Tool Steel Angle Channel exporter in Nigeria, H11 Tool Steel Angle Channel exporter in Gambia, H11 Tool Steel Angle Channel exporter in Indonesia, H11 Tool Steel Angle Channel exporter in Finland, H11 Tool Steel Angle Channel exporter in Argentina, H11 Tool Steel Angle Channel exporter in Chile, H11 Tool Steel Angle Channel exporter in Spain, H11 Tool Steel Angle Channel exporter in Peru, H11 Tool Steel Angle Channel exporter in Kuwait, H11 Tool Steel Angle Channel exporter in India, H11 Tool Steel Angle Channel exporter in Saudi Arabia, H11 Tool Steel Angle Channel exporter in Slovakia, H11 Tool Steel Angle Channel exporter in Slovenia, H11 Tool Steel Angle Channel exporter in Spain, H11 Tool Steel Angle Channel exporter in Sweden, H11 Tool Steel Angle Channel exporter in Switzerland, H11 Tool Steel Angle Channel exporter in Singapore

People Also Search For

SS Sheets Supplier India, SS Coils Supplier India, SS 304 coil price list, SS 304 cold rolled coil distributors, SS 304 profile dealers, SS 304 circle price list, SS 304 coil exporter in mumbai, ss 304 coil Supplier in India, SS 304 coil exporter in india, SS 304 coil-circle exporter in mumbai, ss 304 blank suppliers, SS 304 coils price, ss 304 circle price list, astm a240 ss 304 circles exporter, ss 304 shim coils, SS 304 coil supplier in mumbai, SS Plates Supplier India, , ss 304 coil cheap price, high quality ss 304 coils stockholder in mumbai india.