H13 Tool Steel Angle Channel Manufacturers in India, H13 Tool Steel Angle Channels Price, SS 2062 Price per kg, H13 Tool Steel Angle Channel 2062 suppliers, H13 Tool Steel Angle Channels Price, H13 Tool Steel Angle Channel Suppliers in UAE, H13 Tool Steel Angle Channel Suppliers UK, H13 Tool Steel Angle Channel Suppliers in Saudi Arabia, H13 Tool Steel Angle Channel Suppliers in Qatar, H13 Tool Steel Angle Channel Suppliers Australia.

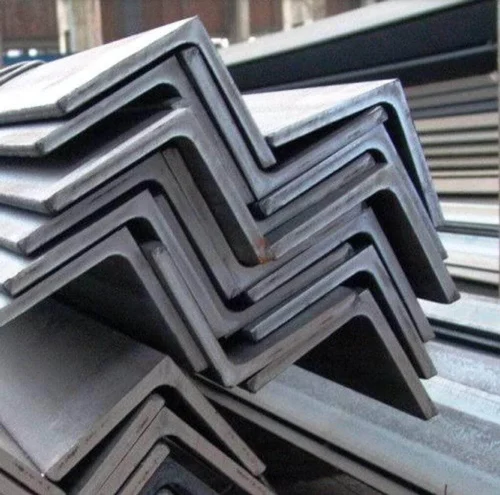

H13 Tool Steel Angle and Channel are premium-grade hot work steels widely recognized for their exceptional combination of toughness, heat resistance, and wear strength. These sections are specifically designed for demanding industrial applications where stability under thermal stress is crucial. H13 maintains consistent mechanical properties even at elevated temperatures, making it ideal for die-casting, extrusion, and forging operations. Its high chromium and molybdenum content provide excellent hardenability and corrosion resistance.

H13 steel angles and channels are precisely manufactured through hot rolling and precision machining processes to achieve tight dimensional tolerances. They undergo rigorous heat treatment, including hardening and tempering, to enhance durability and impact strength. The material’s uniform grain structure ensures superior machinability and polishability. These sections can also be nitrided or coated to extend service life in high-friction environments. Manufacturers ensure consistent metallurgical integrity throughout each section.

One of the defining attributes of H13 Tool Steel Angles and Channels is their outstanding thermal fatigue resistance. The alloy retains hardness even under cyclic heating and cooling, which prevents cracking or deformation during use. It offers superior tensile and yield strength compared to many other tool steels. This makes it a preferred choice for tooling applications involving repeated thermal shocks, such as die inserts, mandrels, and extrusion dies.

H13 Tool Steel Angles and Channels are extensively used in industries like automotive, aerospace, and die-casting where performance under heat and stress is vital. They are also ideal for molds, forging dies, cutting tools, and pressure die components. The material’s ability to maintain structural stability under heavy loads ensures reliability in tooling and mechanical support systems. Many engineers choose H13 over H11 due to its slightly higher resistance to softening and cracking.

H13’s balanced composition of chromium, vanadium, and molybdenum contributes to its excellent oxidation and heat resistance. These angles and channels can operate continuously in high-temperature environments without scaling or losing hardness. The alloy’s protective oxide layer resists corrosion in both air and moist conditions. As a result, it performs exceptionally well in molds that are frequently exposed to molten metals or hot gases.

Despite its hardness, H13 Tool Steel remains relatively easy to machine and fabricate when properly annealed. The steel can be welded with adequate preheating and post-weld tempering to prevent cracking. Its ability to achieve a high surface finish after polishing makes it suitable for precision mold and die applications. Engineers can also customize the hardness through controlled tempering processes, ensuring the right balance between toughness and wear resistance.

H13 Tool Steel Angles and Channels are available in various dimensions to suit multiple industrial frameworks and construction requirements. Their exceptional combination of hot hardness, strength, and stability gives them a long service life, reducing maintenance costs and downtime. With global availability and compliance to standards such as ASTM A681, these sections represent reliability and performance. They are a top choice for engineers seeking durable and thermally stable steel profiles.

Specification Table

| Property | Specification |

|---|---|

| Grade | H13 Tool Steel |

| Standard | AISI H13 / ASTM A681 / DIN 1.2344 / JIS SKD61 |

| Product Forms | Angle, Channel, Flat, Round, and Square Bars |

| Density | 7.80 g/cm³ |

| Melting Point | 1427°C (2600°F) |

| Modulus of Elasticity | ~210 GPa |

| Hardness (Annealed) | ~200 HB |

| Hardness (Hardened & Tempered) | 48–52 HRC |

| Tensile Strength | Up to 1600 MPa (depending on heat treatment) |

| Heat Treatment | Preheat at 870°C, Harden at 1020–1050°C, Temper at 540–650°C |

| Surface Finish | Hot Rolled / Polished / Ground |

| Weldability | Good (with preheating and post-weld tempering) |

| Applications | Forging dies, die-casting molds, extrusion dies, mandrels, and hot shear blades |

| Availability | Available in standard and custom sizes in both angles and channels |

Chemical Composition (Typical ranges for SSIS)

Note: Values are typical ranges. Final composition will be confirmed on MTC provided per lot.

| Element | Symbol | Percentage (%) | Purpose / Effect |

|---|---|---|---|

| Carbon | C | 0.32 – 0.45 | Improves hardness, strength, and wear resistance |

| Chromium | Cr | 4.75 – 5.50 | Enhances corrosion resistance and hardenability |

| Molybdenum | Mo | 1.10 – 1.75 | Increases high-temperature strength and toughness |

| Vanadium | V | 0.80 – 1.20 | Refines grain size, enhances strength, and improves wear resistance |

| Silicon | Si | 0.80 – 1.20 | Improves strength and oxidation resistance |

| Manganese | Mn | 0.20 – 0.50 | Enhances hardness and deoxidizes the steel |

| Phosphorus (max) | P | 0.03 (max) | Kept low to improve toughness |

| Sulfur (max) | S | 0.03 (max) | Kept low to enhance machinability and toughness |

| Iron | Fe | Balance | Base metal providing overall matrix structure |

Mechanical Properties (Typical)

| Property | Condition | Typical Value | Description / Remarks |

|---|---|---|---|

| Tensile Strength | Hardened & Tempered | 1000 – 1600 MPa | High tensile strength suitable for hot work applications |

| Yield Strength | Hardened & Tempered | 800 – 1200 MPa | Provides high resistance to plastic deformation under load |

| Elongation | Hardened & Tempered | 8 – 15% | Shows moderate ductility with good toughness |

| Reduction of Area | Hardened & Tempered | 35 – 50% | Indicates good hot-work fatigue resistance |

| Impact Strength (Charpy V-notch) | At Room Temperature | ≥ 25 J | Ensures toughness and resistance to cracking |

| Hardness (Annealed) | Annealed Condition | ~200 HB | Soft for machining and forming before heat treatment |

| Hardness (Hardened & Tempered) | After Heat Treatment | 48 – 52 HRC | Excellent wear and heat resistance for tooling applications |

| Modulus of Elasticity | — | ~210 GPa | Indicates rigidity and elastic behavior under stress |

| Poisson’s Ratio | — | 0.27 – 0.30 | Represents the ratio of lateral to axial strain |

| Thermal Conductivity | At 100°C | 28 – 32 W/m·K | Good heat transfer for hot-working dies |

| Coefficient of Thermal Expansion | 20–100°C | 10.8 × 10⁻⁶ /°C | Low expansion ensures dimensional stability under heat |

Equivalent Grades

| Standard | Country / Region | Grade Designation | Remarks |

|---|---|---|---|

| AISI / ASTM | United States | H13 | Standard hot-work tool steel used widely in tooling and die industries |

| UNS | United States | T20813 | Unified Numbering System designation for H13 steel |

| DIN | Germany / Europe | 1.2344 / X40CrMoV5-1 | Common European equivalent with similar composition and performance |

| BS | United Kingdom | BH13 / BD3 | British Standard equivalent grade for H13 tool steel |

| JIS | Japan | SKD61 | Widely used Japanese equivalent; same mechanical and heat treatment properties |

| GOST | Russia | 4Kh5MFS | Russian standard equivalent for hot-work die steel |

| ISO | International | X40CrMoV5-1 | International standard designation for H13 type hot-work tool steel |

Dimension & Weight Chart (Selected common sizes)

Below is a representative chart showing outside diameter, wall thickness, inside diameter, cross-sectional area of metal and calculated weight per metre (kg/m). Values are calculated using density = 7.93 g/cm³ and are for guidance — use actual MTC values for procurement & engineering.

| Section Type | Size (mm) | Thickness (mm) | Length (m) | Weight per Meter (kg/m) | Approx. Weight per 6m (kg) |

|---|---|---|---|---|---|

| Angle | 25 × 25 | 3 | 6 | 1.10 | 6.60 |

| Angle | 40 × 40 | 4 | 6 | 2.40 | 14.40 |

| Angle | 50 × 50 | 5 | 6 | 3.70 | 22.20 |

| Angle | 75 × 75 | 6 | 6 | 6.60 | 39.60 |

| Angle | 100 × 100 | 8 | 6 | 9.60 | 57.60 |

| Channel | 75 × 40 | 4.8 | 6 | 5.90 | 35.40 |

| Channel | 100 × 50 | 5 | 6 | 7.10 | 42.60 |

| Channel | 125 × 65 | 5.3 | 6 | 9.60 | 57.60 |

| Channel | 150 × 75 | 6 | 6 | 12.70 | 76.20 |

| Channel | 200 × 100 | 8 | 6 | 18.60 | 111.60 |

Types Of H13 Tool Steel Angal channel

Stainless Steel Angal & channel

Monel 400 Angal & channel

Inconel 600 Angal & channel

Aluminium Bronze Angal & channel

Super Duplex Angal & channel

Duplex Angal & channel

Nickel Angal & channel

Monel K500 Angal & channel

Frequently Asked Questions (FAQ)

What is H13 Tool Steel Angle & Channel?

H13 Tool Steel Angle & Channel are structural components made from H13 hot work tool steel, known for its excellent toughness, heat resistance, and dimensional stability. These profiles are widely used in die casting, extrusion, and hot forging applications due to their ability to withstand high temperatures without deformation.

What are the key properties of H13 Tool Steel?

H13 Tool Steel exhibits high hot hardness, excellent thermal fatigue resistance, and outstanding toughness. It retains its strength at elevated temperatures and offers good machinability in the annealed condition. Its balanced composition makes it ideal for tooling exposed to both thermal and mechanical stress.

Where are H13 Tool Steel Angles & Channels commonly used?

These sections are typically used in tooling applications such as die-casting molds, extrusion dies, forging dies, and hot shear blades. Additionally, H13 Tool Steel Angles & Channels are used in heavy machinery components and parts that operate under high thermal conditions.

What is the hardness range of H13 Tool Steel?

When properly heat-treated, H13 Tool Steel achieves a hardness range of approximately 44–52 HRC. This level of hardness ensures wear resistance and strength for long tool life in demanding high-temperature environments.

Can H13 Tool Steel Angles & Channels be welded or machined?

Yes, H13 can be welded with proper preheating and post-weld heat treatment to avoid cracking. It also offers good machinability in the annealed state and can be precisely finished before hardening and tempering to meet dimensional requirements.

Angle Channels Supplier

Mumbai, Delhi, Kolkata, Chennai, Bengaluru, Hyderabad, Ahmadabad, Pune, Surat, Jaipur, Kanpur, Lucknow, Nagpur, Ghaziabad, Indore, Coimbatore, Kochi, Patna, Kozhikode, Thrissur, Vadodara, Agra, Malappuram, Thiruvananthapuram, Kannur, Ludhiana, Nashik, Noida, Madrid, Sharjah, Moscow, Hong Kong, Lagos, Montreal, Bogota, Los Angeles, New Delhi, Jeddah, Chennai, Kanpur, Edmonton, Istanbul, Bhopal, Calgary, Ulsan, Rio de Janeiro, Colombo, Cairo, Ludhiana, Indore, Thane, Dubai, Seoul, Santiago, Kuwait City, Dammam, Tehran, Busan, Rajkot, Nagpur, La Victoria, Bangkok, Granada, Lahore, Manama

Angle Channels Exporter

H13 Tool Steel Angle Channel exporter South Korea, H13 Tool Steel Angle Channel exporter in South Africa, H13 Tool Steel Angle Channel exporter in Sri Lanka, H13 Tool Steel Angle Channel exporter in Syria, H13 Tool Steel Angle Channel exporter in Taiwan, H13 Tool Steel Angle Channel exporter in Tanzania, H13 Tool Steel Angle Channel exporter in Tajikistan, H13 Tool Steel Angle Channel exporter in Thailand, H13 Tool Steel Angle Channel exporter in Turkey, H13 Tool Steel Angle Channel exporter in Turkmenistan, H13 Tool Steel Angle Channel exporter in Ukraine, H13 Tool Steel Angle Channel exporter in United Kingdom, H13 Tool Steel Angle Channel exporter in United Arab Emirates (UAE), H13 Tool Steel Angle Channel exporter in Uzbekistan, H13 Tool Steel Angle Channel exporter in Vietnam, H13 Tool Steel Angle Channel exporter in Yemen, H13 Tool Steel Angle Channel exporter in France, H13 Tool Steel Angle Channel exporter in Germany, H13 Tool Steel Angle Channel exporter in Greece, H13 Tool Steel Angle Channel exporter in Oman, H13 Tool Steel Angle Channel exporter in Colombia, H13 Tool Steel Angle Channel exporter in Portugal, H13 Tool Steel Angle Channel exporter in Japan, H13 Tool Steel Angle Channel exporter in Lithuania, H13 Tool Steel Angle Channel exporter in Macau, H13 Tool Steel Angle Channel exporter in Mongolia, H13 Tool Steel Angle Channel exporter in Qatar, H13 Tool Steel Angle Channel exporter in Ireland, H13 Tool Steel Angle Channel exporter in Malaysia, H13 Tool Steel Angle Channel exporter in Bangladesh, H13 Tool Steel Angle Channel exporter in United Kingdom, H13 Tool Steel Angle Channel exporter in Russia, H13 Tool Steel Angle Channel exporter in Iran, H13 Tool Steel Angle Channel exporter in Vietnam, H13 Tool Steel Angle Channel exporter in Jordan, H13 Tool Steel Angle Channel exporter in Yemen, H13 Tool Steel Angle Channel exporter in South Africa, H13 Tool Steel Angle Channel exporter in Singapore, H13 Tool Steel Angle Channel exporter in Sri Lanka, H13 Tool Steel Angle Channel exporter in Thailand, H13 Tool Steel Angle Channel exporter in Bulgaria, H13 Tool Steel Angle Channel exporter in Poland, H13 Tool Steel Angle Channel exporter in Denmark, H13 Tool Steel Angle Channel exporter in Nigeria, H13 Tool Steel Angle Channel exporter in Gambia, H13 Tool Steel Angle Channel exporter in Indonesia, H13 Tool Steel Angle Channel exporter in Finland, H13 Tool Steel Angle Channel exporter in Argentina, H13 Tool Steel Angle Channel exporter in Chile, H13 Tool Steel Angle Channel exporter in Spain, H13 Tool Steel Angle Channel exporter in Peru, H13 Tool Steel Angle Channel exporter in Kuwait, H13 Tool Steel Angle Channel exporter in India, H13 Tool Steel Angle Channel exporter in Saudi Arabia, H13 Tool Steel Angle Channel exporter in Slovakia, H13 Tool Steel Angle Channel exporter in Slovenia, H13 Tool Steel Angle Channel exporter in Spain, H13 Tool Steel Angle Channel exporter in Sweden, H13 Tool Steel Angle Channel exporter in Switzerland, H13 Tool Steel Angle Channel exporter in Singapore

People Also Search For

SS Sheets Supplier India, SS Coils Supplier India, SS 304 coil price list, SS 304 cold rolled coil distributors, SS 304 profile dealers, SS 304 circle price list, SS 304 coil exporter in mumbai, ss 304 coil Supplier in India, SS 304 coil exporter in india, SS 304 coil-circle exporter in mumbai, ss 304 blank suppliers, SS 304 coils price, ss 304 circle price list, astm a240 ss 304 circles exporter, ss 304 shim coils, SS 304 coil supplier in mumbai, SS Plates Supplier India, , ss 304 coil cheap price, high quality ss 304 coils stockholder in mumbai india.