Inconel 600 Angle Channel Manufacturers in India, Inconel 600 Angle Channels Price, SS 2062 Price per kg, Inconel 600 Angle Channel 2062 suppliers, Inconel 600 Angle Channels Price, Inconel 600 Angle Channel Suppliers in UAE, Inconel 600 Angle Channel Suppliers UK, Inconel 600 Angle Channel Suppliers in Saudi Arabia, Inconel 600 Angle Channel Suppliers in Qatar, Inconel 600 Angle Channel Suppliers Australia.

Inconel 600 Angle Channel is a nickel-chromium alloy designed to offer superior resistance to oxidation, carburization, and other forms of high-temperature corrosion. Its excellent mechanical properties make it suitable for applications in chemical and marine environments. The alloy maintains stability and strength even under elevated temperatures, providing long-term performance in demanding industrial setups.

This alloy is particularly useful in environments exposed to heat and corrosive chemicals, such as heat-treating equipment, furnace components, and nuclear engineering. Inconel 600 angle channels are often used in structures that must withstand high-pressure and thermal cycling without losing mechanical integrity. The material’s toughness and formability also make it suitable for both welded and cold-formed constructions.

The composition of Inconel 600 includes high levels of nickel and chromium, providing exceptional resistance against a wide range of corrosive agents. It performs reliably in both oxidizing and reducing environments, offering protection in alkaline and chloride-containing solutions. The presence of nickel gives it an edge over stainless steels when it comes to stress-corrosion cracking resistance.

Industries such as petrochemical, aerospace, and marine engineering rely on Inconel 600 Angle Channels for building durable and corrosion-proof frameworks. Its versatility extends to heat exchangers, pressure vessels, and boiler components. The material is also favored for use in caustic evaporators and other equipment exposed to aggressive chemicals and gases at high temperatures.

Mechanical strength and stability are among the most notable features of this alloy. Inconel 600 retains its structural integrity in both cryogenic and elevated temperature conditions. Its excellent creep resistance and metallurgical stability make it a dependable choice for industries requiring long-term exposure to extreme conditions without degradation or loss of toughness.

In addition to its high mechanical properties, Inconel 600 Angle Channels exhibit excellent formability and weldability. The alloy can be fabricated through standard processes such as welding, machining, and forming without the risk of cracking. This flexibility ensures its suitability for diverse industrial applications, from marine equipment to chemical reactors and furnace liners.

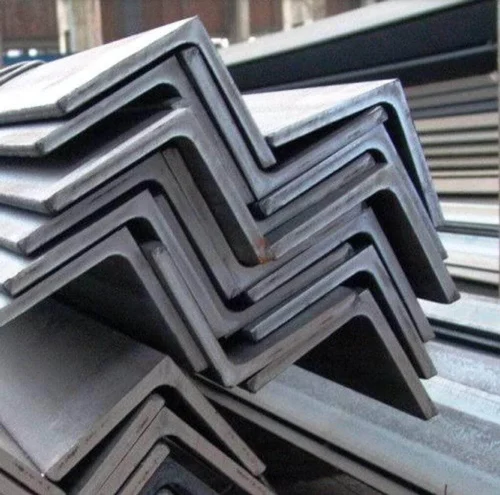

Inconel 600 Angle Channel is available in various sizes and finishes, offering customization based on project requirements. Common forms include equal and unequal angle sections, supplied in mill finish or custom-polished surfaces. With a perfect balance of strength, corrosion resistance, and thermal stability, Inconel 600 is a trusted material for heavy-duty, high-performance structural uses across industries.

Specification Table

| Alloy Designation | Inconel 600 (Nickel-Chromium Alloy) |

| UNS Number | UNS N06600 |

| Product Form | Angle channel (equal & unequal angles) — cut to length, mill finish or custom finish |

| Chemical Composition (typical, wt.% ) | Ni: balance; Cr: 14–17%; Fe: 6–10%; C < 0.15%; Mn < 1%; Si < 0.5%; Cu < 0.5% (values are typical ranges) |

| Density | ~8.47 g/cm³ (approx. 0.306 lb/in³) |

| Melting Range | ~1,350–1,370 °C (2,460–2,500 °F) — approximate |

| Tensile Strength (UTS) | ~655–860 MPa (95–125 ksi) depending on temper and thickness |

| Yield Strength (0.2% offset) | ~275–480 MPa (40–70 ksi) depending on temper and processing |

| Elongation (in 50 mm) | ~20–40% (depends on section size and cold work) |

| Hardness (typical) | ~170–220 HB (varies with strain hardening / heat treatment) |

| Modulus of Elasticity | ~207 GPa (30,000 ksi) |

| Poisson’s Ratio | ~0.30 |

| Operating Temperature Range | Continuous service up to ~1,000 °C (1,800 °F); short-term higher temperatures possible — depends on environment and mechanical load |

| Corrosion Resistance | Excellent resistance to oxidation, carburization and many corrosive environments including some reducing and chloride-containing media; superior to many stainless steels in certain high-temperature or caustic environments |

| Fabrication | Good formability, weldability, and machinability with appropriate procedures; may require care to avoid work-hardening and to control distortion during welding |

| Surface Finish | Mill finish standard; options: pickled, polished, or custom coatings available on request |

| Available Sizes | Custom cut-to-length angles; typical leg widths and thicknesses available per manufacturer — contact supplier for exact stock sizes and tolerances |

| Standards & Compliance | Supplied to common industry specifications upon request (e.g., typical ASTM/ASME/AMS standards for nickel alloys). Confirm exact standard numbers and certifications with supplier. |

| Typical Applications | Furnace and heat-treating equipment, chemical processing, petrochemical, marine components, heat exchangers, and high-temperature structural supports |

| Notes | Values shown are typical and for reference only. For design, welding procedures, certifications, or precise material mill test reports (MTRs), consult the material supplier or refer to applicable standards and material datasheets. |

Chemical Composition (Typical ranges for SSIS)

Note: Values are typical ranges. Final composition will be confirmed on MTC provided per lot.

| Element | Symbol | Content (% by weight) |

|---|---|---|

| Nickel (Ni) | Ni | 72.0 min (Balance) |

| Chromium (Cr) | Cr | 14.0 – 17.0 |

| Iron (Fe) | Fe | 6.0 – 10.0 |

| Carbon (C) | C | 0.15 max |

| Manganese (Mn) | Mn | 1.00 max |

| Sulfur (S) | S | 0.015 max |

| Silicon (Si) | Si | 0.50 max |

| Copper (Cu) | Cu | 0.50 max |

| Other Elements | - | Trace elements may be present in minimal quantities as per standard limits |

Mechanical Properties (Typical)

| Property | Metric | Imperial |

|---|---|---|

| Tensile Strength | 655 – 860 MPa | 95 – 125 ksi |

| Yield Strength (0.2% Offset) | 275 – 480 MPa | 40 – 70 ksi |

| Elongation (in 50 mm) | 30 – 40% | 30 – 40% |

| Hardness (Brinell) | 170 – 220 HB | 170 – 220 HB |

| Modulus of Elasticity | 207 GPa | 30,000 ksi |

| Poisson’s Ratio | 0.30 | 0.30 |

| Melting Range | 1350 – 1370 °C | 2460 – 2500 °F |

| Density | 8.47 g/cm³ | 0.306 lb/in³ |

| Coefficient of Expansion (20–100°C) | 13.3 µm/m°C | 7.4 µin/in°F |

| Thermal Conductivity (at 100°C) | 14.9 W/m·K | 104 BTU·in/hr·ft²·°F |

| Specific Heat (at 25°C) | 444 J/kg·K | 0.106 BTU/lb·°F |

| Electrical Resistivity (at 20°C) | 1.03 µΩ·m | 40.6 µΩ·in |

| Operating Temperature Range | -196°C to 1000°C | -320°F to 1830°F |

Equivalent Grades

| Standard | Grade / Designation | Description / Remarks |

|---|---|---|

| UNS | N06600 | Unified Numbering System designation for Inconel 600 Nickel-Chromium Alloy |

| Werkstoff Nr. (Germany) | 2.4816 | Equivalent material number used in European and German standards |

| ASTM | B166 / B168 / B564 / B366 / B167 | Specifications covering bars, sheets, forgings, fittings, and tubes of Nickel-Chromium-Iron Alloy (Inconel 600) |

| ASME | SB166 / SB168 / SB564 / SB366 / SB167 | ASME equivalent standards for pressure vessel and high-temperature applications |

| EN | NiCr15Fe | European designation; Nickel-Chromium alloy with Iron addition |

| JIS (Japan) | NCF 600 | Japanese Industrial Standard equivalent for Inconel 600 |

| BS (United Kingdom) | NA 14 | British Standard designation for Nickel-Chromium-Iron Alloy 600 |

| ISO | NiCr15Fe | ISO standard chemical designation for nickel-chromium alloy 600 |

| AFNOR (France) | NC15FE | French designation corresponding to Inconel 600 |

| GOST (Russia) | ХН60МБ (KhN60MB) | Russian equivalent grade for Nickel-Chromium Alloy 600 |

| Trade Names | Inconel® 600, Nickel Alloy 600 | Common trade and commercial names used worldwide |

Dimension & Weight Chart (Selected common sizes)

Below is a representative chart showing outside diameter, wall thickness, inside diameter, cross-sectional area of metal and calculated weight per metre (kg/m). Values are calculated using density = 7.93 g/cm³ and are for guidance — use actual MTC values for procurement & engineering.

| Leg Size (mm) | Thickness (mm) | Length (m) | Approx. Weight (kg/m) | Approx. Weight (kg/length) |

|---|---|---|---|---|

| 25 × 25 | 3 | 6 | 1.1 | 6.6 |

| 30 × 30 | 3 | 6 | 1.3 | 7.8 |

| 40 × 40 | 4 | 6 | 2.1 | 12.6 |

| 50 × 50 | 5 | 6 | 3.3 | 19.8 |

| 60 × 60 | 6 | 6 | 4.8 | 28.8 |

| 65 × 65 | 6 | 6 | 5.2 | 31.2 |

| 75 × 75 | 6 | 6 | 6.0 | 36.0 |

| 80 × 80 | 8 | 6 | 8.0 | 48.0 |

| 90 × 90 | 8 | 6 | 9.0 | 54.0 |

| 100 × 100 | 10 | 6 | 12.2 | 73.2 |

| 110 × 110 | 10 | 6 | 13.5 | 81.0 |

| 120 × 120 | 12 | 6 | 17.0 | 102.0 |

| 130 × 130 | 12 | 6 | 18.5 | 111.0 |

| 150 × 150 | 12 | 6 | 21.3 | 127.8 |

| 150 × 150 | 15 | 6 | 26.4 | 158.4 |

| 200 × 200 | 15 | 6 | 35.4 | 212.4 |

| 200 × 200 | 20 | 6 | 45.5 | 273.0 |

| 250 × 250 | 20 | 6 | 56.8 | 340.8 |

Types Of Inconel 600 Angal channel

Stainless Steel Angal & channel

Monel 400 Angal & channel

Inconel 600 Angal & channel

Hastelloy Angal & channel

Super Duplex Angal & channel

Duplex Angal & channel

Nickel Angal & channel

Monel K500 Angal & channel

Frequently Asked Questions (FAQ)

What is Inconel® 600 and why is it used for angle channels?

Inconel® 600 (UNS N06600) is a nickel-chromium-iron alloy known for excellent resistance to oxidation, carburization and many corrosive media at elevated temperatures. It is widely used for angle channels where long-term mechanical strength, thermal stability and resistance to aggressive environments are required. The combination of high nickel content and chromium gives it superior resistance compared with many stainless steels in high-temperature or caustic applications. This makes it suitable for heat-treating, chemical processing, and marine environments where durability and lifecycle cost matter.

What are the common applications for Inconel 600 angle channels?

Typical applications include furnace components and fixtures, heat exchanger supports, boiler and petrochemical structural members, parts exposed to high-temperature oxidizing atmospheres, and marine hardware. They are also used in chemical plants, power generation equipment, and anywhere thermal cycling combined with corrosive exposure would shorten the life of conventional steels. Custom structural parts fabricated from angle channels often serve as load-bearing members in high-temperature systems.

What sizes and forms are available for Inconel 600 angle channels?

Inconel 600 angle channels are supplied in a variety of leg widths, thicknesses and lengths — both equal and unequal leg sections. Common stock sizes vary by mill and distributor; cut-to-length, mill-finished or polished finishes can be ordered. For precise project requirements, suppliers typically provide custom lengths, matched tolerances, and certified mill test reports (MTRs) on request.

How do I calculate the weight of an Inconel 600 angle channel?

Weight is calculated from the cross-sectional area, material density (~8.47 g/cm³), and length. Many suppliers publish weight-per-meter charts for common leg and thickness combinations (see the Dimension & Weight Chart). For precise calculations use the exact section geometry and density, or ask the supplier for certified weights if your design requires tight tolerances.

Is Inconel 600 weldable and how should it be fabricated?

Yes — Inconel 600 is generally weldable by common processes (TIG, MIG, arc welding) when proper precautions are taken. Preweld cleaning, appropriate filler metallurgy, and controlled heat input reduce distortion and avoid excessive work-hardening. Post-weld heat treatment is not typically required for many applications, but welding procedures should be validated for critical service and thick sections.

Angle Channels Supplier

Mumbai, Delhi, Kolkata, Chennai, Bengaluru, Hyderabad, Ahmadabad, Pune, Surat, Jaipur, Kanpur, Lucknow, Nagpur, Ghaziabad, Indore, Coimbatore, Kochi, Patna, Kozhikode, Thrissur, Vadodara, Agra, Malappuram, Thiruvananthapuram, Kannur, Ludhiana, Nashik, Noida, Madrid, Sharjah, Moscow, Hong Kong, Lagos, Montreal, Bogota, Los Angeles, New Delhi, Jeddah, Chennai, Kanpur, Edmonton, Istanbul, Bhopal, Calgary, Ulsan, Rio de Janeiro, Colombo, Cairo, Ludhiana, Indore, Thane, Dubai, Seoul, Santiago, Kuwait City, Dammam, Tehran, Busan, Rajkot, Nagpur, La Victoria, Bangkok, Granada, Lahore, Manama

Angle Channels Exporter

Inconel 600 Angle Channel exporter South Korea, Inconel 600 Angle Channel exporter in South Africa, Inconel 600 Angle Channel exporter in Sri Lanka, Inconel 600 Angle Channel exporter in Syria, Inconel 600 Angle Channel exporter in Taiwan, Inconel 600 Angle Channel exporter in Tanzania, Inconel 600 Angle Channel exporter in Tajikistan, Inconel 600 Angle Channel exporter in Thailand, Inconel 600 Angle Channel exporter in Turkey, Inconel 600 Angle Channel exporter in Turkmenistan, Inconel 600 Angle Channel exporter in Ukraine, Inconel 600 Angle Channel exporter in United Kingdom, Inconel 600 Angle Channel exporter in United Arab Emirates (UAE), Inconel 600 Angle Channel exporter in Uzbekistan, Inconel 600 Angle Channel exporter in Vietnam, Inconel 600 Angle Channel exporter in Yemen, Inconel 600 Angle Channel exporter in France, Inconel 600 Angle Channel exporter in Germany, Inconel 600 Angle Channel exporter in Greece, Inconel 600 Angle Channel exporter in Oman, Inconel 600 Angle Channel exporter in Colombia, Inconel 600 Angle Channel exporter in Portugal, Inconel 600 Angle Channel exporter in Japan, Inconel 600 Angle Channel exporter in Lithuania, Inconel 600 Angle Channel exporter in Macau, Inconel 600 Angle Channel exporter in Mongolia, Inconel 600 Angle Channel exporter in Qatar, Inconel 600 Angle Channel exporter in Ireland, Inconel 600 Angle Channel exporter in Malaysia, Inconel 600 Angle Channel exporter in Bangladesh, Inconel 600 Angle Channel exporter in United Kingdom, Inconel 600 Angle Channel exporter in Russia, Inconel 600 Angle Channel exporter in Iran, Inconel 600 Angle Channel exporter in Vietnam, Inconel 600 Angle Channel exporter in Jordan, Inconel 600 Angle Channel exporter in Yemen, Inconel 600 Angle Channel exporter in South Africa, Inconel 600 Angle Channel exporter in Singapore, Inconel 600 Angle Channel exporter in Sri Lanka, Inconel 600 Angle Channel exporter in Thailand, Inconel 600 Angle Channel exporter in Bulgaria, Inconel 600 Angle Channel exporter in Poland, Inconel 600 Angle Channel exporter in Denmark, Inconel 600 Angle Channel exporter in Nigeria, Inconel 600 Angle Channel exporter in Gambia, Inconel 600 Angle Channel exporter in Indonesia, Inconel 600 Angle Channel exporter in Finland, Inconel 600 Angle Channel exporter in Argentina, Inconel 600 Angle Channel exporter in Chile, Inconel 600 Angle Channel exporter in Spain, Inconel 600 Angle Channel exporter in Peru, Inconel 600 Angle Channel exporter in Kuwait, Inconel 600 Angle Channel exporter in India, Inconel 600 Angle Channel exporter in Saudi Arabia, Inconel 600 Angle Channel exporter in Slovakia, Inconel 600 Angle Channel exporter in Slovenia, Inconel 600 Angle Channel exporter in Spain, Inconel 600 Angle Channel exporter in Sweden, Inconel 600 Angle Channel exporter in Switzerland, Inconel 600 Angle Channel exporter in Singapore

People Also Search For

SS Sheets Supplier India, SS Coils Supplier India, SS 304 coil price list, SS 304 cold rolled coil distributors, SS 304 profile dealers, SS 304 circle price list, SS 304 coil exporter in mumbai, ss 304 coil Supplier in India, SS 304 coil exporter in india, SS 304 coil-circle exporter in mumbai, ss 304 blank suppliers, SS 304 coils price, ss 304 circle price list, astm a240 ss 304 circles exporter, ss 304 shim coils, SS 304 coil supplier in mumbai, SS Plates Supplier India, , ss 304 coil cheap price, high quality ss 304 coils stockholder in mumbai india.