Inconel 625 Angle Channel Manufacturers in India, Inconel 625 Angle Channels Price, SS 2062 Price per kg, Inconel 625 Angle Channel 2062 suppliers, Inconel 625 Angle Channels Price, Inconel 625 Angle Channel Suppliers in UAE, Inconel 625 Angle Channel Suppliers UK, Inconel 625 Angle Channel Suppliers in Saudi Arabia, Inconel 625 Angle Channel Suppliers in Qatar, Inconel 625 Angle Channel Suppliers Australia.

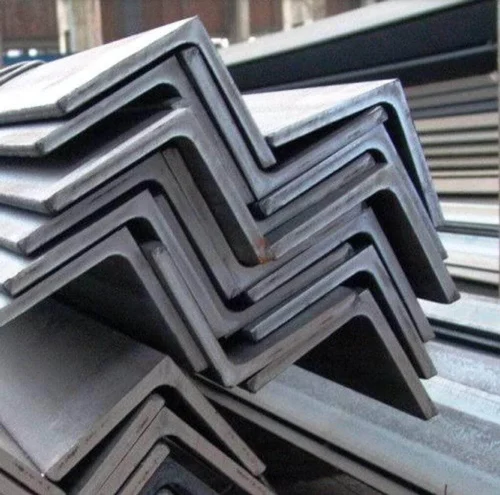

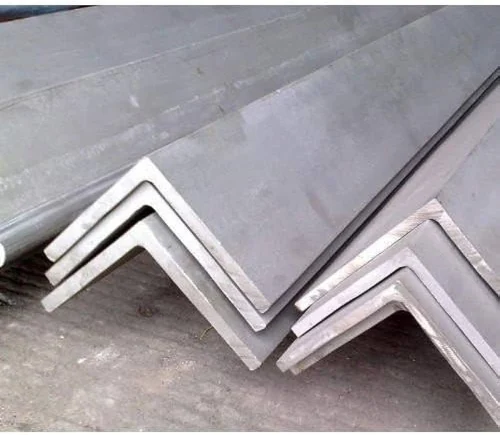

Inconel 625 Angle Channel is a nickel-chromium-molybdenum alloy known for its exceptional strength, corrosion resistance, and thermal stability. This alloy offers outstanding performance in both oxidizing and reducing environments, making it ideal for chemical, marine, and aerospace industries. The addition of molybdenum and niobium enhances its toughness and resistance to pitting and crevice corrosion. It maintains its mechanical integrity even under high-stress and high-temperature conditions. Due to its superior resistance to chloride-ion stress cracking, Inconel 625 is often used in seawater applications and offshore engineering environments.

Inconel 625 Angle Channels are produced through hot or cold rolling processes, ensuring excellent dimensional accuracy and surface finish. The alloy is easily fabricated and welded by conventional methods without post-weld heat treatment, which adds to its versatility. Heat treatment can further improve its mechanical properties, optimizing strength and ductility. These channels undergo solution annealing between 1090°C–1205°C followed by rapid cooling to retain a high degree of corrosion resistance. The precision-controlled manufacturing process ensures uniformity in structure and mechanical strength throughout.

The primary advantages of Inconel 625 Angle Channel include outstanding resistance to a wide range of corrosive media, high tensile strength, and fatigue resistance. It exhibits exceptional oxidation resistance up to 982°C (1800°F), making it suitable for high-temperature operations. Its superior weldability, without cracking or distortion, adds to its usability in complex assemblies. The alloy’s ability to withstand pressure and heat makes it ideal for power plants, heat exchangers, and exhaust systems. Its long service life reduces maintenance costs and enhances performance efficiency.

Inconel 625 Angle Channels are widely used across industries such as marine engineering, aerospace, power generation, chemical processing, and pollution control equipment. In aerospace, they are utilized for turbine shroud rings, exhaust ducts, and jet engine components due to their excellent heat resistance. In chemical industries, these channels serve in reactors, heat exchangers, and piping systems exposed to corrosive chemicals. Offshore and marine applications rely on Inconel 625 for its resistance to saltwater and marine atmospheres. It’s also used in the manufacturing of pressure vessels and nuclear reactor cores.

One of the hallmark features of Inconel 625 Angle Channel is its exceptional corrosion resistance in a broad spectrum of environments. It resists oxidation, carburization, and nitriding even under extreme conditions. The nickel content ensures resistance to chloride-ion stress corrosion cracking, while molybdenum and niobium enhance pitting and crevice corrosion resistance. This makes the alloy particularly suitable for acidic and seawater environments. Its performance in oxidizing acids such as nitric acid and reducing acids like hydrochloric acid makes it ideal for chemical plant applications.

Inconel 625 Angle Channel exhibits high tensile, yield, and creep-rupture strength across a wide temperature range. It retains toughness and ductility even at cryogenic temperatures. The alloy’s density, modulus of elasticity, and thermal expansion coefficients make it dimensionally stable under stress. Its non-magnetic nature and high fatigue strength make it advantageous for specialized engineering applications. Even after prolonged exposure to high temperatures, it maintains its microstructural stability and mechanical reliability.

Every Inconel 625 Angle Channel undergoes stringent quality testing, including chemical analysis, mechanical testing, and dimensional inspection. Manufacturers adhere to international standards such as ASTM B446, ASME SB446, and AMS 5666 to ensure product reliability. These channels are available in various thicknesses, widths, and lengths to suit project requirements. They can also be custom fabricated to specific tolerances and finishes. With its unmatched durability, precision, and performance, Inconel 625 Angle Channel continues to be a preferred choice for demanding industrial environments.

Specification Table

| Specification | Details |

|---|---|

| Product | Inconel 625 Angle Channel |

| Standard | ASTM B446 / ASME SB446, ASTM B564 / ASME SB564 |

| Grade | Inconel Alloy 625 (UNS N06625) |

| Form | Angle, Channel, Flat, Equal & Unequal Angle Bars |

| Size Range | 20 mm x 20 mm to 150 mm x 150 mm (or as required) |

| Thickness | 3 mm to 12 mm |

| Length | 3000 mm, 6000 mm, or custom cut length |

| Finish | Hot Rolled, Cold Drawn, Polished, Bright Finish |

| Manufacturing Process | Hot Rolled / Cold Rolled / Extruded |

| Applications | Chemical Processing, Marine Equipment, Power Generation, Aerospace Structures |

Chemical Composition (Typical ranges for SSIS)

Note: Values are typical ranges. Final composition will be confirmed on MTC provided per lot.

| Element | Content (%) |

|---|---|

| Nickel (Ni) | 58.0 min |

| Chromium (Cr) | 20.0 – 23.0 |

| Molybdenum (Mo) | 8.0 – 10.0 |

| Niobium + Tantalum (Nb + Ta) | 3.15 – 4.15 |

| Iron (Fe) | 5.0 max |

| Manganese (Mn) | 0.50 max |

| Silicon (Si) | 0.50 max |

| Carbon (C) | 0.10 max |

| Phosphorus (P) | 0.015 max |

| Sulfur (S) | 0.015 max |

| Aluminum (Al) | 0.40 max |

| Titanium (Ti) | 0.40 max |

Mechanical Properties (Typical)

| Property | Metric Values | Imperial Values |

|---|---|---|

| Tensile Strength | 827 MPa | 120,000 psi |

| Yield Strength (0.2% Offset) | 414 MPa | 60,000 psi |

| Elongation at Break | 30 – 40 % | 30 – 40 % |

| Hardness (Rockwell B) | 95 HRB max | 95 HRB max |

| Density | 8.44 g/cm³ | 0.305 lb/in³ |

| Melting Point | 1290 – 1350 °C | 2350 – 2460 °F |

| Modulus of Elasticity | 207 GPa | 30,000 ksi |

Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | EN | GRADE |

|---|---|---|---|---|

| ASTM / ASME | 2.4856 | N06625 | NiCr22Mo9Nb | Inconel 625 |

| ISO | 2.4856 | N06625 | NiCr22Mo9Nb | Alloy 625 |

| AFNOR (France) | — | N06625 | NC22DNb | Inconel 625 |

| BS (British Standard) | NA 21 | — | — | Inconel 625 |

| DIN | 2.4856 | — | NiCr22Mo9Nb | Alloy 625 |

| UNS | — | N06625 | — | Inconel 625 |

| JIS (Japan) | — | NW6625 | — | Inconel 625 |

Dimension & Weight Chart (Selected common sizes)

Below is a representative chart showing outside diameter, wall thickness, inside diameter, cross-sectional area of metal and calculated weight per metre (kg/m). Values are calculated using density = 7.93 g/cm³ and are for guidance — use actual MTC values for procurement & engineering.

| Size (mm) | Thickness (mm) | Length (m) | Weight per Meter (kg/m) | Weight per Piece (kg) |

|---|---|---|---|---|

| 25 x 25 | 3 | 6 | 1.15 | 6.90 |

| 40 x 40 | 4 | 6 | 2.50 | 15.00 |

| 50 x 50 | 5 | 6 | 3.85 | 23.10 |

| 65 x 65 | 6 | 6 | 5.90 | 35.40 |

| 75 x 75 | 6 | 6 | 6.95 | 41.70 |

| 90 x 90 | 8 | 6 | 10.15 | 60.90 |

| 100 x 100 | 10 | 6 | 12.60 | 75.60 |

| 125 x 125 | 12 | 6 | 18.10 | 108.60 |

| 150 x 150 | 12 | 6 | 21.60 | 129.60 |

| 200 x 200 | 15 | 6 | 34.20 | 205.20 |

Types Of Inconel 625 Angal channel

Stainless Steel Angal & channel

Monel 400 Angal & channel

Inconel 600 Angal & channel

Hastelloy Angal & channel

Super Duplex Angal & channel

Duplex Angal & channel

Nickel Angal & channel

Monel K500 Angal & channel

Frequently Asked Questions (FAQ)

1. What is Inconel 625 Angle & Channel?

Inconel 625 Angle and Channel are nickel-chromium-molybdenum alloy structural profiles known for exceptional strength, oxidation resistance, and corrosion resistance. They are commonly used in chemical processing, marine environments, and aerospace components where high performance in extreme conditions is required.

2. What are the key properties of Inconel 625?

Inconel 625 offers excellent resistance to chloride-ion stress-corrosion cracking, oxidation, and pitting. It maintains high tensile and creep strength up to 980°C (1800°F). The alloy is also non-magnetic and has excellent weldability without post-weld heat treatment.

3. What standards cover Inconel 625 Angle and Channel?

Inconel 625 conforms to ASTM B443, ASTM B444, ASTM B446, and ASME SB standards. The UNS designation is N06625 and Werkstoff Nr. is 2.4856. These standards ensure consistency in chemical composition, mechanical properties, and manufacturing quality.

4. Where are Inconel 625 Angles and Channels commonly used?

These products are widely used in offshore oil and gas platforms, heat exchangers, chemical processing equipment, pollution control systems, and marine engineering. Their high corrosion and fatigue resistance make them ideal for demanding industrial applications.

5. What are the available sizes and thicknesses for Inconel 625 Angles & Channels?

Inconel 625 Angles and Channels are available in sizes ranging from 25 mm to 200 mm, with thicknesses from 3 mm to 15 mm and standard lengths of 6 meters. Custom sizes can also be fabricated upon request to meet project requirements.

Angle Channels Supplier

Mumbai, Delhi, Kolkata, Chennai, Bengaluru, Hyderabad, Ahmadabad, Pune, Surat, Jaipur, Kanpur, Lucknow, Nagpur, Ghaziabad, Indore, Coimbatore, Kochi, Patna, Kozhikode, Thrissur, Vadodara, Agra, Malappuram, Thiruvananthapuram, Kannur, Ludhiana, Nashik, Noida, Madrid, Sharjah, Moscow, Hong Kong, Lagos, Montreal, Bogota, Los Angeles, New Delhi, Jeddah, Chennai, Kanpur, Edmonton, Istanbul, Bhopal, Calgary, Ulsan, Rio de Janeiro, Colombo, Cairo, Ludhiana, Indore, Thane, Dubai, Seoul, Santiago, Kuwait City, Dammam, Tehran, Busan, Rajkot, Nagpur, La Victoria, Bangkok, Granada, Lahore, Manama

Angle Channels Exporter

Inconel 625 Angle Channel exporter South Korea, Inconel 625 Angle Channel exporter in South Africa, Inconel 625 Angle Channel exporter in Sri Lanka, Inconel 625 Angle Channel exporter in Syria, Inconel 625 Angle Channel exporter in Taiwan, Inconel 625 Angle Channel exporter in Tanzania, Inconel 625 Angle Channel exporter in Tajikistan, Inconel 625 Angle Channel exporter in Thailand, Inconel 625 Angle Channel exporter in Turkey, Inconel 625 Angle Channel exporter in Turkmenistan, Inconel 625 Angle Channel exporter in Ukraine, Inconel 625 Angle Channel exporter in United Kingdom, Inconel 625 Angle Channel exporter in United Arab Emirates (UAE), Inconel 625 Angle Channel exporter in Uzbekistan, Inconel 625 Angle Channel exporter in Vietnam, Inconel 625 Angle Channel exporter in Yemen, Inconel 625 Angle Channel exporter in France, Inconel 625 Angle Channel exporter in Germany, Inconel 625 Angle Channel exporter in Greece, Inconel 625 Angle Channel exporter in Oman, Inconel 625 Angle Channel exporter in Colombia, Inconel 625 Angle Channel exporter in Portugal, Inconel 625 Angle Channel exporter in Japan, Inconel 625 Angle Channel exporter in Lithuania, Inconel 625 Angle Channel exporter in Macau, Inconel 625 Angle Channel exporter in Mongolia, Inconel 625 Angle Channel exporter in Qatar, Inconel 625 Angle Channel exporter in Ireland, Inconel 625 Angle Channel exporter in Malaysia, Inconel 625 Angle Channel exporter in Bangladesh, Inconel 625 Angle Channel exporter in United Kingdom, Inconel 625 Angle Channel exporter in Russia, Inconel 625 Angle Channel exporter in Iran, Inconel 625 Angle Channel exporter in Vietnam, Inconel 625 Angle Channel exporter in Jordan, Inconel 625 Angle Channel exporter in Yemen, Inconel 625 Angle Channel exporter in South Africa, Inconel 625 Angle Channel exporter in Singapore, Inconel 625 Angle Channel exporter in Sri Lanka, Inconel 625 Angle Channel exporter in Thailand, Inconel 625 Angle Channel exporter in Bulgaria, Inconel 625 Angle Channel exporter in Poland, Inconel 625 Angle Channel exporter in Denmark, Inconel 625 Angle Channel exporter in Nigeria, Inconel 625 Angle Channel exporter in Gambia, Inconel 625 Angle Channel exporter in Indonesia, Inconel 625 Angle Channel exporter in Finland, Inconel 625 Angle Channel exporter in Argentina, Inconel 625 Angle Channel exporter in Chile, Inconel 625 Angle Channel exporter in Spain, Inconel 625 Angle Channel exporter in Peru, Inconel 625 Angle Channel exporter in Kuwait, Inconel 625 Angle Channel exporter in India, Inconel 625 Angle Channel exporter in Saudi Arabia, Inconel 625 Angle Channel exporter in Slovakia, Inconel 625 Angle Channel exporter in Slovenia, Inconel 625 Angle Channel exporter in Spain, Inconel 625 Angle Channel exporter in Sweden, Inconel 625 Angle Channel exporter in Switzerland, Inconel 625 Angle Channel exporter in Singapore

People Also Search For

SS Sheets Supplier India, SS Coils Supplier India, SS 304 coil price list, SS 304 cold rolled coil distributors, SS 304 profile dealers, SS 304 circle price list, SS 304 coil exporter in mumbai, ss 304 coil Supplier in India, SS 304 coil exporter in india, SS 304 coil-circle exporter in mumbai, ss 304 blank suppliers, SS 304 coils price, ss 304 circle price list, astm a240 ss 304 circles exporter, ss 304 shim coils, SS 304 coil supplier in mumbai, SS Plates Supplier India, , ss 304 coil cheap price, high quality ss 304 coils stockholder in mumbai india.