Inconel 718 Angle Channel Manufacturers in India, Inconel 718 Angle Channels Price, SS 2062 Price per kg, Inconel 718 Angle Channel 2062 suppliers, Inconel 718 Angle Channels Price, Inconel 718 Angle Channel Suppliers in UAE, Inconel 718 Angle Channel Suppliers UK, Inconel 718 Angle Channel Suppliers in Saudi Arabia, Inconel 718 Angle Channel Suppliers in Qatar, Inconel 718 Angle Channel Suppliers Australia.

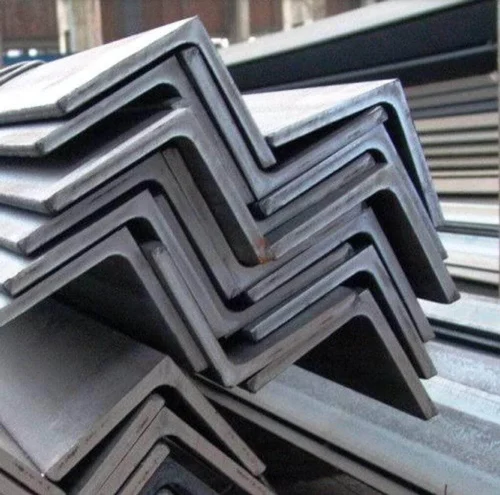

Inconel 718 Angle and Channel are premium nickel-chromium alloys known for their exceptional strength, corrosion resistance, and oxidation stability at high temperatures. These sections are widely used in applications where extreme environments demand superior mechanical properties. The alloy maintains its strength even when exposed to temperatures as high as 700°C, making it ideal for aerospace, marine, and power generation industries. Its high yield strength and excellent weldability make fabrication and installation easier compared to other superalloys.

One of the defining characteristics of Inconel 718 Angle and Channel is its outstanding resistance to pitting, crevice corrosion, and chloride-ion stress cracking. This makes it suitable for use in both oxidizing and reducing environments. The alloy’s combination of niobium, molybdenum, and titanium enhances its hardenability and strength without compromising its ductility. It can easily withstand corrosive chemicals, acids, and seawater, ensuring a longer service life in aggressive environments.

Inconel 718 Angles and Channels are commonly used in jet engines, gas turbines, cryogenic tanks, and high-pressure vessels. The alloy’s ability to retain toughness and fatigue strength at sub-zero and elevated temperatures gives it a distinct advantage in critical engineering applications. Its precise chemical composition enables easy machinability and allows for complex structural designs. Whether for structural supports or framework, these components offer reliability and durability.

Fabrication of Inconel 718 Angle and Channel involves advanced techniques such as hot or cold forming followed by age hardening to achieve maximum strength. The material is known for its ability to resist deformation under heavy mechanical stress. It can be readily welded using standard processes, ensuring structural integrity in welded joints. Due to its stable microstructure, the alloy maintains excellent creep and rupture strength even under prolonged exposure to heat.

The mechanical strength and corrosion resistance of Inconel 718 make it a preferred choice for marine and offshore industries. Components made from this alloy can withstand saltwater exposure and maintain their properties even after long-term service. Its superior performance under pressure and temperature variations makes it a reliable material for demanding engineering projects. The alloy’s versatility extends from industrial to chemical processing environments where performance and longevity are critical.

Inconel 718 Angle and Channel are supplied in various sizes and dimensions to meet diverse project specifications. They can be manufactured in both hot-rolled and cold-rolled conditions, offering flexibility for different structural needs. The alloy’s consistent surface finish and dimensional accuracy make it ideal for both functional and aesthetic applications. Custom sizes, finishes, and tolerances can be provided to meet specific design requirements.

Overall, Inconel 718 Angle and Channel deliver a perfect combination of high strength, corrosion resistance, and thermal stability. They are an ideal choice for industries that operate under harsh mechanical and thermal stress. Their performance and reliability have made them a trusted solution in critical sectors worldwide. Investing in Inconel 718 ensures long-term durability, reduced maintenance, and superior performance in the most challenging environments.

Specification Table

| Parameter | Specification |

|---|---|

| Material Grade | Inconel 718 |

| UNS | N07718 |

| Standard | ASTM B637 / AMS 5662 / AMS 5663 |

| Form | Angle, Channel, Custom Profiles |

| Size Range | Angles: 10mm to 150mm; Channels: 20mm to 200mm (custom sizes available) |

| Length | 3 Meters, 6 Meters or Custom Cut Lengths |

| Condition | Solution Annealed & Age Hardened |

| Density | 8.19 g/cm³ |

| Melting Point | 1260°C – 1336°C |

| Finish | Hot Rolled, Cold Drawn, Pickled, or Polished |

| Applications | Aerospace, Turbine Components, Cryogenic Tanks, Power Generation, and Chemical Processing |

| Testing | Mechanical Testing, Chemical Analysis, PMI, and NDT Available |

Chemical Composition (Typical ranges for SSIS)

Note: Values are typical ranges. Final composition will be confirmed on MTC provided per lot.

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 50.00 – 55.00 |

| Chromium (Cr) | 17.00 – 21.00 |

| Iron (Fe) | Balance |

| Niobium + Tantalum (Nb + Ta) | 4.75 – 5.50 |

| Molybdenum (Mo) | 2.80 – 3.30 |

| Titanium (Ti) | 0.65 – 1.15 |

| Aluminum (Al) | 0.20 – 0.80 |

| Cobalt (Co) | ≤ 1.00 |

| Carbon (C) | ≤ 0.08 |

| Manganese (Mn) | ≤ 0.35 |

| Silicon (Si) | ≤ 0.35 |

| Sulfur (S) | ≤ 0.015 |

| Phosphorus (P) | ≤ 0.015 |

| Boron (B) | ≤ 0.006 |

| Copper (Cu) | ≤ 0.30 |

Mechanical Properties (Typical)

| Property | Condition | Value | Units |

|---|---|---|---|

| Tensile Strength | Age Hardened | 930 – 1200 | MPa |

| Yield Strength (0.2% Offset) | Age Hardened | ≥ 720 | MPa |

| Elongation | In 50 mm | ≥ 10 | % |

| Reduction of Area | Typical | ≥ 12 | % |

| Hardness | Age Hardened | 331 – 380 | HB |

| Impact Strength (Charpy V-Notch) | Room Temperature | ≥ 100 | J |

| Modulus of Elasticity | Room Temperature | ~ 200 | GPa |

| Density | — | 8.19 | g/cm³ |

| Melting Point | — | 1260 – 1336 | °C |

| Thermal Conductivity | At 100°C | 11.4 | W/m·K |

| Coefficient of Thermal Expansion | 20°C – 1000°C | 13.0 ×10⁻⁶ | /°C |

Equivalent Grades

| Standard | Equivalent Grade |

|---|---|

| UNS | N07718 |

| Werkstoff Nr. | 2.4668 |

| ASTM | B637 |

| AMS | 5662 / 5663 / 5832 |

| BS | NA 51 |

| AFNOR | NC 20FeNb |

| GOST | ЭИ437Б (EI437B) |

| EN | NiCr19Fe19Nb5Mo3 |

| ISO | NiCr19Fe19Nb5Mo3 |

Dimension & Weight Chart (Selected common sizes)

Below is a representative chart showing outside diameter, wall thickness, inside diameter, cross-sectional area of metal and calculated weight per metre (kg/m). Values are calculated using density = 7.93 g/cm³ and are for guidance — use actual MTC values for procurement & engineering.

| Size (mm) | Leg (A) x Leg (B) x Thickness (T) | Weight (kg/m) | Section Type |

|---|---|---|---|

| 25 x 25 x 3 | 25 x 25 x 3 | 1.10 | Equal Angle |

| 40 x 40 x 4 | 40 x 40 x 4 | 2.37 | Equal Angle |

| 50 x 50 x 5 | 50 x 50 x 5 | 3.67 | Equal Angle |

| 65 x 65 x 6 | 65 x 65 x 6 | 5.78 | Equal Angle |

| 75 x 75 x 6 | 75 x 75 x 6 | 6.75 | Equal Angle |

| 100 x 100 x 8 | 100 x 100 x 8 | 10.8 | Equal Angle |

| 50 x 25 x 4 | 50 x 25 x 4 | 2.78 | Unequal Angle |

| 65 x 50 x 5 | 65 x 50 x 5 | 4.35 | Unequal Angle |

| 75 x 50 x 6 | 75 x 50 x 6 | 5.56 | Unequal Angle |

| 100 x 65 x 6 | 100 x 65 x 6 | 7.47 | Unequal Angle |

| 75 x 40 x 5 | 75 x 40 x 5 | 4.85 | Unequal Angle |

| 100 x 50 x 6 | 100 x 50 x 6 | 6.95 | Unequal Angle |

| Channel 100 x 50 x 5 | 100 x 50 x 5 | 8.45 | C Channel |

| Channel 150 x 75 x 6 | 150 x 75 x 6 | 13.85 | C Channel |

| Channel 200 x 100 x 8 | 200 x 100 x 8 | 20.25 | C Channel |

Types Of Inconel 718 Angal channel

Stainless Steel Angal & channel

Monel 400 Angal & channel

Inconel 600 Angal & channel

Hastelloy Angal & channel

Super Duplex Angal & channel

Duplex Angal & channel

Nickel Angal & channel

Monel K500 Angal & channel

Frequently Asked Questions (FAQ)

What is Inconel 718 Angle Channel?

Inconel 718 Angle Channel is a nickel-chromium-based superalloy known for its exceptional strength, corrosion resistance, and ability to retain mechanical properties at temperatures up to 700°C. It is commonly used in aerospace, chemical processing, and marine applications where high performance is required under extreme conditions.

What are the key benefits of Inconel 718 Angle Channel?

The key advantages include outstanding tensile and yield strength, excellent oxidation and corrosion resistance, superior fatigue and creep resistance, and good weldability compared to other nickel alloys. These properties make it ideal for high-stress and high-temperature environments.

What are common applications of Inconel 718 Angle Channel?

Common uses include gas turbines, jet engines, rocket motors, heat exchangers, pressure vessels, and structural supports in high-temperature industries. It is also used in nuclear reactors and marine engineering due to its superior corrosion resistance.

What standards and specifications apply to Inconel 718 Angle Channel?

Inconel 718 Angle Channels are typically manufactured according to ASTM B637 and AMS 5662/5663 standards. The alloy designation is UNS N07718 and Werkstoff Nr. 2.4668. Always verify specific standards and test certificates with your supplier before purchase.

Is Inconel 718 Angle Channel easy to machine or fabricate?

Inconel 718 is difficult to machine due to its high strength and work-hardening characteristics. Specialized tools, slower cutting speeds, and adequate cooling are required. However, it offers good weldability and can be fabricated using standard forming and welding methods with proper heat treatment.

Angle Channels Supplier

Mumbai, Delhi, Kolkata, Chennai, Bengaluru, Hyderabad, Ahmadabad, Pune, Surat, Jaipur, Kanpur, Lucknow, Nagpur, Ghaziabad, Indore, Coimbatore, Kochi, Patna, Kozhikode, Thrissur, Vadodara, Agra, Malappuram, Thiruvananthapuram, Kannur, Ludhiana, Nashik, Noida, Madrid, Sharjah, Moscow, Hong Kong, Lagos, Montreal, Bogota, Los Angeles, New Delhi, Jeddah, Chennai, Kanpur, Edmonton, Istanbul, Bhopal, Calgary, Ulsan, Rio de Janeiro, Colombo, Cairo, Ludhiana, Indore, Thane, Dubai, Seoul, Santiago, Kuwait City, Dammam, Tehran, Busan, Rajkot, Nagpur, La Victoria, Bangkok, Granada, Lahore, Manama

Angle Channels Exporter

Inconel 718 Angle Channel exporter South Korea, Inconel 718 Angle Channel exporter in South Africa, Inconel 718 Angle Channel exporter in Sri Lanka, Inconel 718 Angle Channel exporter in Syria, Inconel 718 Angle Channel exporter in Taiwan, Inconel 718 Angle Channel exporter in Tanzania, Inconel 718 Angle Channel exporter in Tajikistan, Inconel 718 Angle Channel exporter in Thailand, Inconel 718 Angle Channel exporter in Turkey, Inconel 718 Angle Channel exporter in Turkmenistan, Inconel 718 Angle Channel exporter in Ukraine, Inconel 718 Angle Channel exporter in United Kingdom, Inconel 718 Angle Channel exporter in United Arab Emirates (UAE), Inconel 718 Angle Channel exporter in Uzbekistan, Inconel 718 Angle Channel exporter in Vietnam, Inconel 718 Angle Channel exporter in Yemen, Inconel 718 Angle Channel exporter in France, Inconel 718 Angle Channel exporter in Germany, Inconel 718 Angle Channel exporter in Greece, Inconel 718 Angle Channel exporter in Oman, Inconel 718 Angle Channel exporter in Colombia, Inconel 718 Angle Channel exporter in Portugal, Inconel 718 Angle Channel exporter in Japan, Inconel 718 Angle Channel exporter in Lithuania, Inconel 718 Angle Channel exporter in Macau, Inconel 718 Angle Channel exporter in Mongolia, Inconel 718 Angle Channel exporter in Qatar, Inconel 718 Angle Channel exporter in Ireland, Inconel 718 Angle Channel exporter in Malaysia, Inconel 718 Angle Channel exporter in Bangladesh, Inconel 718 Angle Channel exporter in United Kingdom, Inconel 718 Angle Channel exporter in Russia, Inconel 718 Angle Channel exporter in Iran, Inconel 718 Angle Channel exporter in Vietnam, Inconel 718 Angle Channel exporter in Jordan, Inconel 718 Angle Channel exporter in Yemen, Inconel 718 Angle Channel exporter in South Africa, Inconel 718 Angle Channel exporter in Singapore, Inconel 718 Angle Channel exporter in Sri Lanka, Inconel 718 Angle Channel exporter in Thailand, Inconel 718 Angle Channel exporter in Bulgaria, Inconel 718 Angle Channel exporter in Poland, Inconel 718 Angle Channel exporter in Denmark, Inconel 718 Angle Channel exporter in Nigeria, Inconel 718 Angle Channel exporter in Gambia, Inconel 718 Angle Channel exporter in Indonesia, Inconel 718 Angle Channel exporter in Finland, Inconel 718 Angle Channel exporter in Argentina, Inconel 718 Angle Channel exporter in Chile, Inconel 718 Angle Channel exporter in Spain, Inconel 718 Angle Channel exporter in Peru, Inconel 718 Angle Channel exporter in Kuwait, Inconel 718 Angle Channel exporter in India, Inconel 718 Angle Channel exporter in Saudi Arabia, Inconel 718 Angle Channel exporter in Slovakia, Inconel 718 Angle Channel exporter in Slovenia, Inconel 718 Angle Channel exporter in Spain, Inconel 718 Angle Channel exporter in Sweden, Inconel 718 Angle Channel exporter in Switzerland, Inconel 718 Angle Channel exporter in Singapore

People Also Search For

SS Sheets Supplier India, SS Coils Supplier India, SS 304 coil price list, SS 304 cold rolled coil distributors, SS 304 profile dealers, SS 304 circle price list, SS 304 coil exporter in mumbai, ss 304 coil Supplier in India, SS 304 coil exporter in india, SS 304 coil-circle exporter in mumbai, ss 304 blank suppliers, SS 304 coils price, ss 304 circle price list, astm a240 ss 304 circles exporter, ss 304 shim coils, SS 304 coil supplier in mumbai, SS Plates Supplier India, , ss 304 coil cheap price, high quality ss 304 coils stockholder in mumbai india.