Naval Brass (C46400) Angle Channel Manufacturers in India, Naval Brass (C46400) Angle Channels Price, SS 2062 Price per kg, Naval Brass (C46400) Angle Channel 2062 suppliers, Naval Brass (C46400) Angle Channels Price, Naval Brass (C46400) Angle Channel Suppliers in UAE, Naval Brass (C46400) Angle Channel Suppliers UK, Naval Brass (C46400) Angle Channel Suppliers in Saudi Arabia, Naval Brass (C46400) Angle Channel Suppliers in Qatar, Naval Brass (C46400) Angle Channel Suppliers Australia.

Naval Brass (C46400) Angle and Channel products are known for their exceptional strength, durability, and resistance to corrosion in marine environments. Composed mainly of copper, zinc, and tin, this alloy delivers a unique balance of toughness and machinability, making it suitable for numerous engineering and structural applications. Its excellent resistance to dezincification and saltwater corrosion makes it a top choice for shipbuilding, marine hardware, and offshore installations.

The addition of a small amount of tin in C46400 enhances its corrosion resistance beyond that of typical brass alloys. This property ensures long-term stability and minimal maintenance in seawater and brine conditions. Moreover, Naval Brass exhibits superior wear resistance, making it ideal for applications involving friction and movement such as bearings, bushings, and propeller shafts. The material retains its integrity even under cyclic loading and high humidity conditions.

Naval Brass Angles and Channels are typically produced in various tempers, including soft, half-hard, and hard tempers, to suit specific forming or machining requirements. The alloy demonstrates excellent hot working characteristics and fair cold workability. Due to its high tensile strength, it is often employed in fabrications requiring both mechanical robustness and aesthetic appeal. It also possesses a golden-yellow sheen that enhances its decorative use in architectural design and interior fixtures.

In marine applications, Naval Brass (C46400) performs exceptionally well in both freshwater and saltwater environments. It resists pitting and stress corrosion cracking, providing long-lasting service even in harsh conditions. Components made from this alloy maintain their dimensional accuracy and surface finish, making them suitable for precision-engineered parts like valve bodies, shafts, and fasteners. It is also frequently used for condenser plates, pump parts, and hardware exposed to seawater.

One of the key reasons Naval Brass is preferred over other brass grades is its improved strength-to-weight ratio and superior corrosion resistance. It maintains consistent performance even at elevated temperatures, making it reliable in industrial heat exchanger systems and power plants. Its inherent resistance to biofouling ensures lower maintenance costs in marine environments. Naval Brass is also non-sparking, which makes it safe for use in explosive or high-risk operational zones.

The machinability of C46400 Naval Brass is rated as good, providing smooth chip formation and reduced tool wear during machining operations. It can be easily soldered, brazed, and welded using suitable techniques. When polished, it provides an appealing bright finish, enhancing both functional and decorative uses. Common surface finishes include mill finish, brushed, and mirror-polished types. The alloy’s versatility makes it a staple for fabricators across multiple industries.

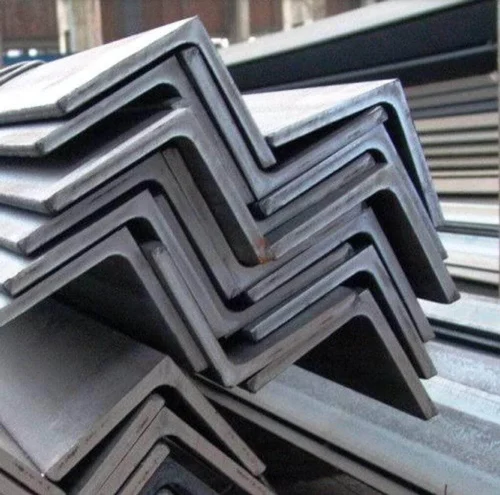

Naval Brass (C46400) Angles and Channels are widely available in different dimensions and cross-sections to meet various design needs. Standard dimensions include equal and unequal angles as well as C- and U-type channels. Custom sizes can also be fabricated upon request to meet specific engineering drawings. With its combination of strength, corrosion resistance, and formability, Naval Brass remains one of the most reliable materials for marine and architectural applications worldwide.

Specification Table

| Property | Specification |

|---|---|

| Material Name | Naval Brass |

| UNS Designation | C46400 |

| Standard Specification | ASTM B21, ASTM B124, ASTM B171, ASTM B453 |

| Form | Angle, Channel, Rod, Bar, Plate, Sheet |

| Copper (Cu) Content | Approx. 59.0% - 62.0% |

| Zinc (Zn) Content | Balance |

| Tin (Sn) Content | 0.75% - 1.00% |

| Temper | Soft (O), Half Hard (H02), Hard (H04) |

| Density | 8.44 g/cm³ |

| Melting Point | 930°C - 950°C (1710°F - 1740°F) |

| Electrical Conductivity | 26% IACS (approx.) |

| Corrosion Resistance | Excellent in seawater and marine environments |

| Machinability Rating | 30% (compared to free-cutting brass = 100) |

| Typical Applications | Marine hardware, ship fittings, condenser plates, pump shafts, architectural trims |

Chemical Composition (Typical ranges for SSIS)

Note: Values are typical ranges. Final composition will be confirmed on MTC provided per lot.

| Element | Composition (%) |

|---|---|

| Copper (Cu) | 59.0 – 62.0 |

| Lead (Pb) | ≤ 0.10 |

| Iron (Fe) | ≤ 0.10 |

| Tin (Sn) | 0.75 – 1.00 |

| Zinc (Zn) | Balance |

| Others (Total) | ≤ 0.30 |

Mechanical Properties (Typical)

| Property | Value | Condition / Temper |

|---|---|---|

| Tensile Strength | 380 – 550 MPa | Annealed to Hard |

| Yield Strength (0.2% Offset) | 150 – 345 MPa | Annealed to Hard |

| Elongation | 10 – 35% | Dependent on temper |

| Brinell Hardness (HB) | 80 – 150 | Soft to Hard |

| Modulus of Elasticity | 105 GPa | Typical |

| Density | 8.44 g/cm³ | At 20°C |

| Melting Point | 930 – 950°C | Solidus–Liquidus Range |

Equivalent Grades

| Standard | Equivalent Grade | Description |

|---|---|---|

| UNS | C46400 | Naval Brass |

| ASTM | B21 / B124 / B171 / B453 | Standard specifications for Naval Brass Rod, Bar, and Shapes |

| BS (British Standard) | CZ112 | Naval Brass, Lead-free, High-strength and Corrosion-resistant |

| EN (European Standard) | CuZn37Sn1 | Naval Brass with Tin addition for marine resistance |

| JIS (Japan) | C4640 | Naval Brass equivalent in Japanese standard |

| ISO | CuZn37Sn1 | International equivalent for Naval Brass alloy |

| DIN (Germany) | 2.0475 | Equivalent designation for Naval Brass in German standards |

Dimension & Weight Chart (Selected common sizes)

Below is a representative chart showing outside diameter, wall thickness, inside diameter, cross-sectional area of metal and calculated weight per metre (kg/m). Values are calculated using density = 7.93 g/cm³ and are for guidance — use actual MTC values for procurement & engineering.

| Size (mm) | Leg (A × B) | Thickness (mm) | Weight (kg/m) | Approx. Cross-Section Area (mm²) |

|---|---|---|---|---|

| 20 × 20 | Equal Angle | 3 | 0.85 | 101 |

| 25 × 25 | Equal Angle | 3 | 1.05 | 125 |

| 30 × 30 | Equal Angle | 4 | 1.60 | 190 |

| 40 × 40 | Equal Angle | 5 | 2.75 | 325 |

| 50 × 50 | Equal Angle | 6 | 4.00 | 470 |

| 65 × 65 | Equal Angle | 6 | 5.25 | 615 |

| 75 × 75 | Equal Angle | 8 | 7.95 | 930 |

| 100 × 50 | Channel Section | 6 | 7.85 | 920 |

| 125 × 65 | Channel Section | 6 | 9.75 | 1150 |

| 150 × 75 | Channel Section | 8 | 13.60 | 1610 |

Types Of Naval Brass Angal channel

Stainless Steel Angal & channel

Monel 400 Angal & channel

Inconel 600 Angal & channel

Hastelloy Angal & channel

Super Duplex Angal & channel

Duplex Angal & channel

Nickel Angal & channel

Monel K500 Angal & channel

Frequently Asked Questions (FAQ)

What is Naval Brass C46400 and why is it used for angles & channels?

Naval Brass (UNS C46400) is a copper-zinc-tin alloy formulated for improved seawater corrosion resistance and strength. In angle and channel profiles it combines structural capability with good resistance to dezincification and pitting, making it ideal for marine hardware, architectural trim, pump and valve parts, and other components exposed to aggressive environments.

What are the typical chemical elements and their ranges in C46400?

C46400 is primarily copper with zinc as the balance, plus tin (typically ~0.75–1.0%) to stabilize against dezincification. Trace amounts of iron, lead (very low or controlled), and other elements may be present per specification. Always check supplier mill certificates for exact batch analysis.

Which tempers are available and how do they affect forming and strength?

Common tempers include annealed (soft, O), half-hard (H02) and hard (H04). Annealed material is easiest to form and bend; half-hard and hard tempers increase yield and tensile strength but reduce elongation. Choose temper based on required forming operations or load-bearing needs.

How does Naval Brass perform in seawater and corrosive environments?

C46400 shows excellent resistance to seawater corrosion, including reduced susceptibility to dezincification compared with standard brasses. It resists pitting and stress-corrosion cracking better than many Cu-Zn alloys, but long-term exposure should be assessed per application. For critical parts, laboratory or field testing is recommended.

Is Naval Brass machinable, weldable, and suitable for brazing/soldering?

Naval Brass offers good machinability (not as high as free-cutting brasses) with smooth chip formation and reasonable tool life. It can be soldered and brazed readily; welding is possible with appropriate procedures and pre/post heat treatment when needed. Consult welding/brazing guidelines for joint design and filler compatibility.

Angle Channels Supplier

Mumbai, Delhi, Kolkata, Chennai, Bengaluru, Hyderabad, Ahmadabad, Pune, Surat, Jaipur, Kanpur, Lucknow, Nagpur, Ghaziabad, Indore, Coimbatore, Kochi, Patna, Kozhikode, Thrissur, Vadodara, Agra, Malappuram, Thiruvananthapuram, Kannur, Ludhiana, Nashik, Noida, Madrid, Sharjah, Moscow, Hong Kong, Lagos, Montreal, Bogota, Los Angeles, New Delhi, Jeddah, Chennai, Kanpur, Edmonton, Istanbul, Bhopal, Calgary, Ulsan, Rio de Janeiro, Colombo, Cairo, Ludhiana, Indore, Thane, Dubai, Seoul, Santiago, Kuwait City, Dammam, Tehran, Busan, Rajkot, Nagpur, La Victoria, Bangkok, Granada, Lahore, Manama

Angle Channels Exporter

Naval Brass (C46400) Angle Channel exporter South Korea, Naval Brass (C46400) Angle Channel exporter in South Africa, Naval Brass (C46400) Angle Channel exporter in Sri Lanka, Naval Brass (C46400) Angle Channel exporter in Syria, Naval Brass (C46400) Angle Channel exporter in Taiwan, Naval Brass (C46400) Angle Channel exporter in Tanzania, Naval Brass (C46400) Angle Channel exporter in Tajikistan, Naval Brass (C46400) Angle Channel exporter in Thailand, Naval Brass (C46400) Angle Channel exporter in Turkey, Naval Brass (C46400) Angle Channel exporter in Turkmenistan, Naval Brass (C46400) Angle Channel exporter in Ukraine, Naval Brass (C46400) Angle Channel exporter in United Kingdom, Naval Brass (C46400) Angle Channel exporter in United Arab Emirates (UAE), Naval Brass (C46400) Angle Channel exporter in Uzbekistan, Naval Brass (C46400) Angle Channel exporter in Vietnam, Naval Brass (C46400) Angle Channel exporter in Yemen, Naval Brass (C46400) Angle Channel exporter in France, Naval Brass (C46400) Angle Channel exporter in Germany, Naval Brass (C46400) Angle Channel exporter in Greece, Naval Brass (C46400) Angle Channel exporter in Oman, Naval Brass (C46400) Angle Channel exporter in Colombia, Naval Brass (C46400) Angle Channel exporter in Portugal, Naval Brass (C46400) Angle Channel exporter in Japan, Naval Brass (C46400) Angle Channel exporter in Lithuania, Naval Brass (C46400) Angle Channel exporter in Macau, Naval Brass (C46400) Angle Channel exporter in Mongolia, Naval Brass (C46400) Angle Channel exporter in Qatar, Naval Brass (C46400) Angle Channel exporter in Ireland, Naval Brass (C46400) Angle Channel exporter in Malaysia, Naval Brass (C46400) Angle Channel exporter in Bangladesh, Naval Brass (C46400) Angle Channel exporter in United Kingdom, Naval Brass (C46400) Angle Channel exporter in Russia, Naval Brass (C46400) Angle Channel exporter in Iran, Naval Brass (C46400) Angle Channel exporter in Vietnam, Naval Brass (C46400) Angle Channel exporter in Jordan, Naval Brass (C46400) Angle Channel exporter in Yemen, Naval Brass (C46400) Angle Channel exporter in South Africa, Naval Brass (C46400) Angle Channel exporter in Singapore, Naval Brass (C46400) Angle Channel exporter in Sri Lanka, Naval Brass (C46400) Angle Channel exporter in Thailand, Naval Brass (C46400) Angle Channel exporter in Bulgaria, Naval Brass (C46400) Angle Channel exporter in Poland, Naval Brass (C46400) Angle Channel exporter in Denmark, Naval Brass (C46400) Angle Channel exporter in Nigeria, Naval Brass (C46400) Angle Channel exporter in Gambia, Naval Brass (C46400) Angle Channel exporter in Indonesia, Naval Brass (C46400) Angle Channel exporter in Finland, Naval Brass (C46400) Angle Channel exporter in Argentina, Naval Brass (C46400) Angle Channel exporter in Chile, Naval Brass (C46400) Angle Channel exporter in Spain, Naval Brass (C46400) Angle Channel exporter in Peru, Naval Brass (C46400) Angle Channel exporter in Kuwait, Naval Brass (C46400) Angle Channel exporter in India, Naval Brass (C46400) Angle Channel exporter in Saudi Arabia, Naval Brass (C46400) Angle Channel exporter in Slovakia, Naval Brass (C46400) Angle Channel exporter in Slovenia, Naval Brass (C46400) Angle Channel exporter in Spain, Naval Brass (C46400) Angle Channel exporter in Sweden, Naval Brass (C46400) Angle Channel exporter in Switzerland, Naval Brass (C46400) Angle Channel exporter in Singapore

People Also Search For

Naval Sheets Supplier India, Naval Coils Supplier India, SS 304 coil price list, Naval 304 cold rolled coil distributors, Naval 304 profile dealers, Naval 304 circle price list, Naval 304 coil exporter in mumbai, ss 304 coil Supplier in India, Naval 304 coil exporter in india, Naval 304 coil-circle exporter in mumbai, ss 304 blank suppliers, Naval 304 coils price, ss 304 circle price list, astm a240 ss 304 circles exporter, ss 304 shim coils, Naval 304 coil supplier in mumbai, Naval Plates Supplier India, , ss 304 coil cheap price, high quality ss 304 coils stockholder in mumbai india.