SS 420/420J2 Angle Channel Manufacturers in India, SS 420/420J2 Angle Channels Price, SS 2062 Price per kg, SS 420/420J2 Angle Channel 2062 suppliers, SS 420/420J2 Angle Channels Price, SS 420/420J2 Angle Channel Suppliers in UAE, SS 420/420J2 Angle Channel Suppliers UK, SS 420/420J2 Angle Channel Suppliers in Saudi Arabia, SS 420/420J2 Angle Channel Suppliers in Qatar, SS 420/420J2 Angle Channel Suppliers Australia.

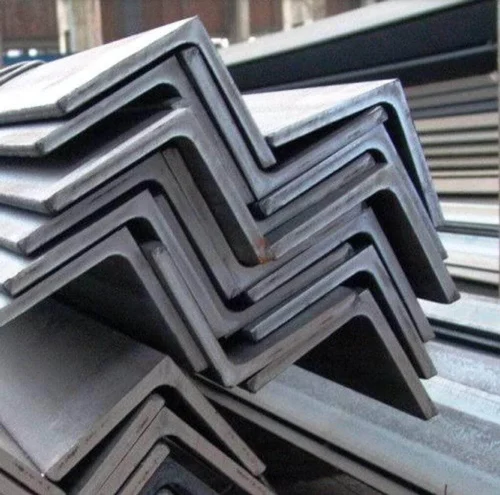

SS 420 / 420J2 Stainless Steel Angle Channels are martensitic stainless steel products known for their exceptional strength, hardness, and moderate corrosion resistance. These channels are designed for structural applications that demand durability, precision, and toughness. With the addition of carbon, the alloy achieves superior wear resistance, making it ideal for use in environments exposed to abrasion and mechanical stress. The SS 420 series offers good polishing characteristics, which is why it is also used in decorative and precision engineering works. Their bright finish and dimensional stability make them an excellent choice for both industrial and architectural projects.

SS 420 and SS 420J2 stainless steels differ mainly in carbon content—420J2 containing slightly less carbon, offering improved toughness but lower hardness compared to SS 420. This balance allows fabricators to select the grade according to their specific performance needs. These angle channels are often heat-treated to improve hardness and tensile strength, achieving optimal performance under heavy mechanical loads. The steel’s inherent ability to maintain edge retention and form stability under heat makes it ideal for cutting tools, mechanical parts, and industrial machinery frames. Its machinability, though moderate, can be improved through controlled heat treatment and grinding processes.

These stainless steel angle channels are highly valued in industries such as chemical processing, construction, marine equipment manufacturing, and automotive applications. In construction, SS 420/420J2 angle channels serve as reinforcements, frameworks, and brackets in load-bearing structures. In the marine industry, they provide excellent durability against water exposure when properly passivated or surface-treated. Additionally, they are used in making shafts, surgical instruments, and hardware components requiring excellent surface finish and hardness. Their versatility ensures they can be easily welded, cut, and machined with standard tools.

The performance of SS 420/420J2 angle channels is enhanced through processes like quenching and tempering, which refine their microstructure to achieve balanced hardness and ductility. Their resistance to scaling and oxidation up to 650°C allows them to perform well in high-temperature service conditions. While not as corrosion-resistant as austenitic grades like 304 or 316, these martensitic steels perform well in dry atmospheres and mildly corrosive environments. Proper surface finishing and maintenance can further extend their service life. Moreover, the channels exhibit minimal distortion during heat treatment, ensuring dimensional accuracy.

In terms of mechanical properties, SS 420/420J2 angle channels demonstrate high tensile strength and yield strength, suitable for heavy-duty applications. The material can achieve a Rockwell hardness of up to 50 HRC when properly hardened. It also maintains good fatigue strength, making it reliable for dynamic load applications. The combination of strength and edge retention is beneficial in manufacturing cutting blades, valves, and pump parts. SS 420J2, with slightly better impact resistance, is frequently used in applications requiring more flexibility and resistance to cracking under stress.

Dimensional accuracy and surface finish are key aspects of SS 420/420J2 angle channels. They are available in equal and unequal leg sizes to suit different fabrication and structural requirements. The channels undergo strict quality control processes including ultrasonic testing, hardness testing, and chemical composition analysis to ensure compliance with ASTM A276 and A484 standards. Their smooth edges and precision geometry make them ideal for aesthetic as well as mechanical assemblies. Custom dimensions and finishes such as brushed, mirror, or matte polish are available upon request.

Overall, SS 420/420J2 Stainless Steel Angle Channels represent an excellent blend of mechanical performance, wear resistance, and affordability. Their robustness makes them perfect for industrial sectors that need reliable structural materials capable of withstanding harsh conditions. Whether used in the fabrication of machine components, architectural structures, or decorative fittings, these angle channels deliver consistent performance and long-term durability. With proper surface treatment and heat control, SS 420/420J2 channels offer a dependable and cost-effective solution for multiple engineering needs.

Specification Table

| Property | Specification / Typical Range | Notes |

|---|---|---|

| Material Grade | SS 420, SS 420J2 | Martensitic stainless steel — heat treatable for higher hardness. |

| Applicable Standards | ASTM A276 / A479 (bars & sections), EN 10088 (reference), JIS where applicable | Verify project-specific standard and MTR requirements with supplier. |

| Product Form | Equal & unequal leg L-angle channel (angles), cut to length or full bars | Available in multiple leg sizes, thicknesses and finishes. |

| Chemical Composition (typical) |

C: 0.15 – 0.50% (420 higher end, 420J2 lower end) Cr: 12.0 – 14.0% Mn: ≤ 1.0% · Si: ≤ 1.0% · P: ≤ 0.04% · S: ≤ 0.03% |

Supplier certificates (MTR) provide exact batch values — use those for critical work. |

| Heat Treatment | Annealed; Quenched & Tempered to achieve required hardness/strength | Quench+temper recommended for wear parts; tempering controls toughness. |

| Tensile Strength (Rm) | ~450 – 850 MPa (varies by heat treatment and carbon content) | Higher values correspond to hardened conditions. |

| Yield Strength (0.2% proof) | ~275 – 650 MPa (typical) | Depends on grade (420 vs 420J2) and temper level. |

| Elongation (A) | ~8 – 20% (annealed toward upper range; tempered/hardened lower) | 420J2 typically shows slightly better elongation/toughness than 420. |

| Hardness |

Annealed: ~170 – 230 HB Hardened/Tempered: up to ~50 HRC (depending on process) |

Specify required hardness for wear or cutting applications. |

| Density | ≈ 7.75 g/cm³ | Use for weight and structural calculations. |

| Melting Range | ~1,420 – 1,530 °C | Indicative range for stainless steels of this family. |

| Surface Finishes | Hot-rolled / pickled, No.4 brushed, BA/mirror (polished) — mill or custom finishes | Finish affects corrosion resistance and appearance; pickling/passivation recommended. |

| Typical Sizes |

Leg lengths: commonly 10 mm – 200 mm Thickness: commonly 2 mm – 20 mm Lengths: standard up to 6 m (cut-to-length options) |

Custom dimensions available on order. |

| Tolerances | Per customer/spec (refer EN/ASTM dimensional tolerances or project spec) | Confirm tolerances for tight-fit or precision assemblies. |

| Testing & Certification | MTR (EN 10204 / ASTM equivalent), chemical analysis, mechanical tests, hardness | Additional NDT (UT, PMI) can be supplied on request for critical parts. |

| Welding | Weldable with recommended filler metals; preheat/post-weld heat treatment advised | Martensitic grades need careful welding procedures to avoid cracking. |

| Typical Applications | Structural frames, machine parts, shafts, valve components, cutting tools, trims | Choose 420J2 for slightly improved toughness where cracking risk exists. |

Chemical Composition (Typical ranges for SSIS)

Note: Values are typical ranges. Final composition will be confirmed on MTC provided per lot.

| Element | SS 420 (%) | SS 420J2 (%) | Remarks |

|---|---|---|---|

| Carbon (C) | 0.15 – 0.50 | 0.16 – 0.25 | Higher carbon in SS 420 for greater hardness |

| Chromium (Cr) | 12.0 – 14.0 | 12.0 – 14.0 | Provides corrosion resistance and hardness |

| Manganese (Mn) | ≤ 1.00 | ≤ 1.00 | Improves toughness and hot working properties |

| Silicon (Si) | ≤ 1.00 | ≤ 1.00 | Enhances strength and oxidation resistance |

| Phosphorus (P) | ≤ 0.040 | ≤ 0.040 | Kept low to improve toughness |

| Sulfur (S) | ≤ 0.030 | ≤ 0.030 | Controlled for better machinability |

| Nickel (Ni) | ≤ 0.75 | ≤ 0.75 | Minor addition enhances corrosion resistance |

| Iron (Fe) | Balance | Balance | Base element |

Mechanical Properties (Typical)

| Property | SS 420 (Typical) | SS 420J2 (Typical) | Remarks |

|---|---|---|---|

| Tensile Strength (MPa) | 650 – 850 | 520 – 700 | Depends on heat treatment and tempering conditions |

| Yield Strength (MPa) | 450 – 650 | 275 – 450 | Varies with grade and hardness condition |

| Elongation (%) | 8 – 15 | 10 – 20 | 420J2 offers better ductility than 420 |

| Hardness (Rockwell C) | Up to 50 HRC (Hardened) | Up to 48 HRC | Annealed condition: ~170–230 HB |

| Impact Strength (Charpy V-notch) | Low to Moderate | Moderate | 420J2 gives improved toughness |

| Modulus of Elasticity (GPa) | ~200 | ~200 | Similar to most stainless steels |

| Density (g/cm³) | 7.75 | 7.75 | Used for weight and section calculations |

| Poisson’s Ratio | 0.27 – 0.30 | 0.27 – 0.30 | Typical range for stainless steels |

| Melting Point (°C) | 1,420 – 1,530 | 1,420 – 1,530 | Approximate range |

Equivalent Grades

| Standard | SS 420 Equivalent Grade | SS 420J2 Equivalent Grade | Country / Specification |

|---|---|---|---|

| ASTM / ASME | ASTM A276 Type 420 | ASTM A276 Type 420J2 | United States |

| EN / DIN | X20Cr13 (1.4021) | X30Cr13 (1.4028) | European Standard (EN 10088) |

| BS (British Standard) | 420S37 | 420S45 | United Kingdom |

| JIS | SUS 420J1 | SUS 420J2 | Japan |

| AFNOR (France) | Z20C13 | Z30C13 | France |

| GOST (Russia) | 20X13 | 30X13 | Russia / CIS |

| UNS Number | S42000 | S42003 | Unified Numbering System |

Dimension & Weight Chart (Selected common sizes)

Below is a representative chart showing outside diameter, wall thickness, inside diameter, cross-sectional area of metal and calculated weight per metre (kg/m). Values are calculated using density = 7.93 g/cm³ and are for guidance — use actual MTC values for procurement & engineering.

| Size (mm) | Leg A × Leg B (mm) | Thickness (mm) | Length (m) | Theoretical Weight (kg/m) | Approx. Weight (kg/6m) |

|---|---|---|---|---|---|

| 20 × 20 × 3 | 20 × 20 | 3 | 6 | 0.88 | 5.28 |

| 25 × 25 × 3 | 25 × 25 | 3 | 6 | 1.10 | 6.60 |

| 30 × 30 × 3 | 30 × 30 | 3 | 6 | 1.32 | 7.92 |

| 40 × 40 × 4 | 40 × 40 | 4 | 6 | 2.40 | 14.40 |

| 50 × 50 × 5 | 50 × 50 | 5 | 6 | 3.70 | 22.20 |

| 60 × 60 × 6 | 60 × 60 | 6 | 6 | 5.30 | 31.80 |

| 70 × 70 × 6 | 70 × 70 | 6 | 6 | 6.25 | 37.50 |

| 75 × 75 × 6 | 75 × 75 | 6 | 6 | 6.90 | 41.40 |

| 90 × 90 × 8 | 90 × 90 | 8 | 6 | 10.60 | 63.60 |

| 100 × 100 × 10 | 100 × 100 | 10 | 6 | 14.80 | 88.80 |

| 120 × 120 × 12 | 120 × 120 | 12 | 6 | 20.80 | 124.80 |

| 150 × 150 × 15 | 150 × 150 | 15 | 6 | 30.50 | 183.00 |

| 200 × 200 × 20 | 200 × 200 | 20 | 6 | 54.00 | 324.00 |

Types Of SS 420/420J2 Angal channel

Stainless Steel Angal & channel

Monel 400 Angal & channel

Inconel 600 Angal & channel

Hastelloy Angal & channel

Super Duplex Angal & channel

Duplex Angal & channel

Nickel Angal & channel

Monel K500 Angal & channel

Frequently Asked Questions (FAQ)

What is SS 420 / 420J2 Stainless Steel Angle Channel?

SS 420 and SS 420J2 Stainless Steel Angle Channels are martensitic stainless steels that offer high hardness, good corrosion resistance, and excellent wear resistance. These channels are widely used in construction, structural supports, and fabrication where strength and durability are crucial.

What are the key differences between SS 420 and SS 420J2?

SS 420 contains a slightly lower carbon content compared to SS 420J2, making it easier to machine and polish. SS 420J2, with higher carbon, provides greater hardness and wear resistance. Both grades can be hardened through heat treatment but vary slightly in mechanical strength and toughness.

What are the common applications of SS 420 / 420J2 Angle Channels?

These stainless steel angle channels are used in industrial machinery, structural frameworks, food processing equipment, chemical industries, automotive parts, surgical tools, and decorative architecture due to their hardness and corrosion resistance.

Can SS 420 and SS 420J2 be welded easily?

Welding SS 420 and 420J2 requires care due to their hardenable nature. Preheating and post-weld heat treatment are recommended to avoid cracking. Specialized filler materials such as 420 or 309 stainless electrodes are often used to maintain corrosion resistance and strength.

What surface finishes are available for SS 420 / 420J2 Angle Channels?

Common finishes include hot rolled, cold drawn, polished (No.4, mirror finish), and bright annealed. The surface finish depends on the intended application—polished finishes are typically used for decorative or hygienic environments.

Angle Channels Supplier

Mumbai, Delhi, Kolkata, Chennai, Bengaluru, Hyderabad, Ahmadabad, Pune, Surat, Jaipur, Kanpur, Lucknow, Nagpur, Ghaziabad, Indore, Coimbatore, Kochi, Patna, Kozhikode, Thrissur, Vadodara, Agra, Malappuram, Thiruvananthapuram, Kannur, Ludhiana, Nashik, Noida, Madrid, Sharjah, Moscow, Hong Kong, Lagos, Montreal, Bogota, Los Angeles, New Delhi, Jeddah, Chennai, Kanpur, Edmonton, Istanbul, Bhopal, Calgary, Ulsan, Rio de Janeiro, Colombo, Cairo, Ludhiana, Indore, Thane, Dubai, Seoul, Santiago, Kuwait City, Dammam, Tehran, Busan, Rajkot, Nagpur, La Victoria, Bangkok, Granada, Lahore, Manama

Angle Channels Exporter

SS 420/420J2 Angle Channel exporter South Korea, SS 420/420J2 Angle Channel exporter in South Africa, SS 420/420J2 Angle Channel exporter in Sri Lanka, SS 420/420J2 Angle Channel exporter in Syria, SS 420/420J2 Angle Channel exporter in Taiwan, SS 420/420J2 Angle Channel exporter in Tanzania, SS 420/420J2 Angle Channel exporter in Tajikistan, SS 420/420J2 Angle Channel exporter in Thailand, SS 420/420J2 Angle Channel exporter in Turkey, SS 420/420J2 Angle Channel exporter in Turkmenistan, SS 420/420J2 Angle Channel exporter in Ukraine, SS 420/420J2 Angle Channel exporter in United Kingdom, SS 420/420J2 Angle Channel exporter in United Arab Emirates (UAE), SS 420/420J2 Angle Channel exporter in Uzbekistan, SS 420/420J2 Angle Channel exporter in Vietnam, SS 420/420J2 Angle Channel exporter in Yemen, SS 420/420J2 Angle Channel exporter in France, SS 420/420J2 Angle Channel exporter in Germany, SS 420/420J2 Angle Channel exporter in Greece, SS 420/420J2 Angle Channel exporter in Oman, SS 420/420J2 Angle Channel exporter in Colombia, SS 420/420J2 Angle Channel exporter in Portugal, SS 420/420J2 Angle Channel exporter in Japan, SS 420/420J2 Angle Channel exporter in Lithuania, SS 420/420J2 Angle Channel exporter in Macau, SS 420/420J2 Angle Channel exporter in Mongolia, SS 420/420J2 Angle Channel exporter in Qatar, SS 420/420J2 Angle Channel exporter in Ireland, SS 420/420J2 Angle Channel exporter in Malaysia, SS 420/420J2 Angle Channel exporter in Bangladesh, SS 420/420J2 Angle Channel exporter in United Kingdom, SS 420/420J2 Angle Channel exporter in Russia, SS 420/420J2 Angle Channel exporter in Iran, SS 420/420J2 Angle Channel exporter in Vietnam, SS 420/420J2 Angle Channel exporter in Jordan, SS 420/420J2 Angle Channel exporter in Yemen, SS 420/420J2 Angle Channel exporter in South Africa, SS 420/420J2 Angle Channel exporter in Singapore, SS 420/420J2 Angle Channel exporter in Sri Lanka, SS 420/420J2 Angle Channel exporter in Thailand, SS 420/420J2 Angle Channel exporter in Bulgaria, SS 420/420J2 Angle Channel exporter in Poland, SS 420/420J2 Angle Channel exporter in Denmark, SS 420/420J2 Angle Channel exporter in Nigeria, SS 420/420J2 Angle Channel exporter in Gambia, SS 420/420J2 Angle Channel exporter in Indonesia, SS 420/420J2 Angle Channel exporter in Finland, SS 420/420J2 Angle Channel exporter in Argentina, SS 420/420J2 Angle Channel exporter in Chile, SS 420/420J2 Angle Channel exporter in Spain, SS 420/420J2 Angle Channel exporter in Peru, SS 420/420J2 Angle Channel exporter in Kuwait, SS 420/420J2 Angle Channel exporter in India, SS 420/420J2 Angle Channel exporter in Saudi Arabia, SS 420/420J2 Angle Channel exporter in Slovakia, SS 420/420J2 Angle Channel exporter in Slovenia, SS 420/420J2 Angle Channel exporter in Spain, SS 420/420J2 Angle Channel exporter in Sweden, SS 420/420J2 Angle Channel exporter in Switzerland, SS 420/420J2 Angle Channel exporter in Singapore

People Also Search For

SS Sheets Supplier India, SS Coils Supplier India, SS 304 coil price list, SS 304 cold rolled coil distributors, SS 304 profile dealers, SS 304 circle price list, SS 304 coil exporter in mumbai, ss 304 coil Supplier in India, SS 304 coil exporter in india, SS 304 coil-circle exporter in mumbai, ss 304 blank suppliers, SS 304 coils price, ss 304 circle price list, astm a240 ss 304 circles exporter, ss 304 shim coils, SS 304 coil supplier in mumbai, SS Plates Supplier India, , ss 304 coil cheap price, high quality ss 304 coils stockholder in mumbai india.