SS XM-19 (Nitronic50) Angle Channel Manufacturers in India, SS XM-19 (Nitronic50) Angle Channels Price, SS 2062 Price per kg, SS XM-19 (Nitronic50) Angle Channel 2062 suppliers, SS XM-19 (Nitronic50) Angle Channels Price, SS XM-19 (Nitronic50) Angle Channel Suppliers in UAE, SS XM-19 (Nitronic50) Angle Channel Suppliers UK, SS XM-19 (Nitronic50) Angle Channel Suppliers in Saudi Arabia, SS XM-19 (Nitronic50) Angle Channel Suppliers in Qatar, SS XM-19 (Nitronic50) Angle Channel Suppliers Australia.

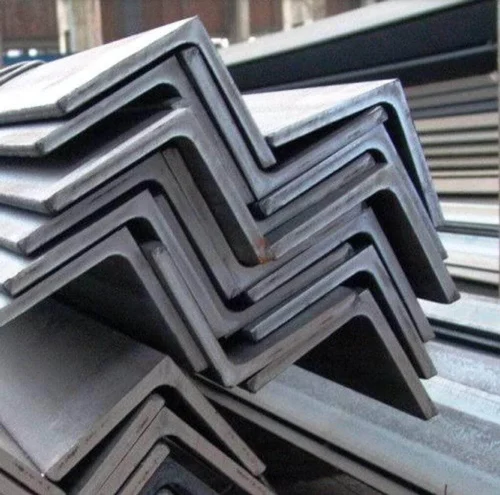

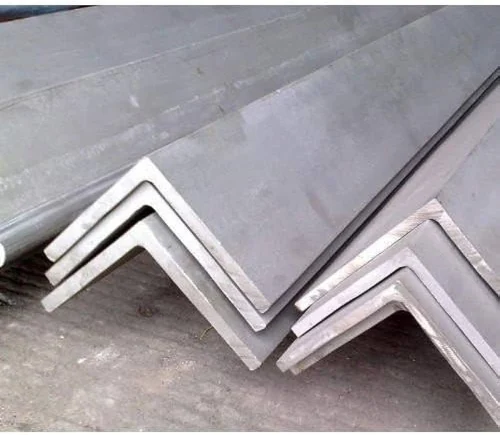

SS XM-19 (market name Nitronic 50) is an austenitic, nitrogen-strengthened stainless alloy prized for its high strength and excellent resistance to stress-corrosion cracking. Its chemistry includes elevated nitrogen and manganese levels (alongside chromium and nickel) which together raise yield strength without resorting to precipitation hardening. As an angle channel, XM-19 delivers a high strength-to-weight ratio useful where structural stiffness and corrosion resistance are required.

Compared with standard 300-series stainless, it offers improved galling resistance and markedly better performance in chloride-bearing environments. Typical angle channel applications include pump and valve components, fasteners, shafts, marine fittings, and corrosive process equipment. The alloy resists hydrogen embrittlement and sensitization better than many austenitics, making it suitable for sour and chloride-laden services. Designers often choose XM-19 when combining mechanical load capacity with reliability in aggressive environments is critical.

Fabrication of XM-19 angle channel follows conventional stainless-steel practices but pays attention to work hardening and springback during forming. Cold forming (bending, rolling) increases strength through strain hardening; annealing can be used to restore ductility when deep drawing or complex forming is required. Welding is readily performed with matching filler metals; pre- and post-weld heat treatment are typically unnecessary for corrosion performance but post-weld stress relief may be used in structural assemblies. Machining is moderate — harder than 304/316 due to nitrogen strengthening — so tooling and feeds should be optimized to avoid excessive tool wear.

Surface finishes such as pickling and passivation restore a uniform oxide layer and improve long-term corrosion resistance after fabrication. When specifying fasteners or bolted connections with XM-19 channel, consider its higher galling resistance to reduce the need for anti-seize coatings. Quality control usually includes dimensional checks, visual surface inspection, and occasional corrosion or hardness tests depending on application risk.

Corrosion behavior of Nitronic 50 angle channel is robust in many media: seawater, fresh and brackish water, many acids, and alkaline environments. It shows superior resistance to pitting and crevice corrosion relative to plain austenitics in chloride environments, though severe chloride stressors still require careful design. Its resistance to stress-corrosion cracking makes it attractive for components under tensile stress in warm chloride environments.

For marine or chemical processing installations, routine inspections and good drainage details further extend service life of angle channel members. When galvanic couples are present, isolate dissimilar metals or match fastener materials to avoid accelerated corrosion at contact points. Coatings or surface treatments can be combined with the alloy’s passive film to handle specific service conditions or aesthetic needs. Specify finish class (mill, 2B, polished) consistent with the intended environment to balance cost and corrosion performance.

Mechanical behavior of XM-19 angle channel centers on high yield and good toughness across a wide temperature range. Strength is obtained primarily through solid solution and nitrogen hardening rather than heat treatment, so cold work is an effective way to tune properties. It retains ductility and fracture toughness at sub-ambient temperatures, which is useful for cryogenic or cold-climate structural parts.

Specification Table

| Specification | Details |

|---|---|

| Material Grade | SS XM-19 / Nitronic 50 |

| UNS Number | S20910 |

| Standards | ASTM A276, ASTM A479, ASTM A182, ASME SA276, ASME SA479 |

| Form | Angle, Channel, Flat Bar, Round Bar, Hex Bar |

| Surface Finish | Black, Bright, Polished, Pickled |

| Dimensions | 25mm x 25mm to 200mm x 200mm (Angle) / Custom Sizes on Request |

| Thickness | 3mm to 20mm |

| Length | 3 Meter, 6 Meter, or Custom Cut Lengths |

| Finish Condition | Hot Rolled (HR), Cold Drawn (CD), Annealed |

| Density | 7.9 g/cm³ |

| Melting Point | 1400°C – 1450°C |

| Hardness (Brinell) | 220 – 260 HB |

| Yield Strength (Annealed) | 379 MPa (55 ksi) Min |

| Tensile Strength | 690 MPa (100 ksi) Min |

| Elongation | 35% Min in 50mm |

| Corrosion Resistance | Excellent in Seawater, Marine, and Chemical Environments |

| Applications | Marine Hardware, Pump Shafts, Valves, Fasteners, Structural Supports |

| Country of Origin | Made in India |

Chemical Composition (Typical ranges for SSIS)

Note: Values are typical ranges. Final composition will be confirmed on MTC provided per lot.

| Element | Percentage (%) |

|---|---|

| Carbon (C) | 0.06 Max |

| Manganese (Mn) | 4.00 – 6.00 |

| Silicon (Si) | 1.00 Max |

| Phosphorus (P) | 0.04 Max |

| Sulfur (S) | 0.03 Max |

| Chromium (Cr) | 20.50 – 23.50 |

| Nickel (Ni) | 11.50 – 13.50 |

| Molybdenum (Mo) | 1.50 – 3.00 |

| Vanadium (V) | 0.10 – 0.30 |

| Columbium + Tantalum (Cb + Ta) | 0.10 – 0.30 |

| Nitrogen (N) | 0.20 – 0.40 |

| Iron (Fe) | Balance |

Mechanical Properties (Typical)

| Property | Condition | Value | Units |

|---|---|---|---|

| Tensile Strength | Annealed | 690 | MPa (100 ksi) |

| Yield Strength (0.2% Offset) | Annealed | 379 | MPa (55 ksi) |

| Elongation | Annealed | 35 | % in 50 mm |

| Reduction of Area | Annealed | 55 | % |

| Hardness | Annealed | 220 – 260 | Brinell (HB) |

| Modulus of Elasticity | — | 193 | GPa |

| Poisson’s Ratio | — | 0.27 – 0.30 | — |

| Density | — | 7.9 | g/cm³ |

| Melting Range | — | 1400 – 1450 | °C |

| Impact Strength | Room Temperature | High | — |

Equivalent Grades

| Standard | Equivalent Grade | Designation / Description |

|---|---|---|

| UNS | S20910 | Unified Numbering System designation for XM-19 (Nitronic 50) |

| ASTM | XM-19 | Standard grade under ASTM A276 / A479 for stainless bars and shapes |

| EN / DIN | 1.3964 | European / German equivalent grade for XM-19 stainless steel |

| BS (British Standard) | 310S31 | Comparable austenitic stainless grade with similar corrosion resistance |

| JIS | SUS XM-19 | Japanese Industrial Standard designation |

| AFNOR (France) | Z2CN20-11 | French equivalent of Nitronic 50 stainless steel |

| ISO | X2CrNiMnMoN21-11-3 | ISO stainless steel designation based on composition |

Dimension & Weight Chart (Selected common sizes)

Below is a representative chart showing outside diameter, wall thickness, inside diameter, cross-sectional area of metal and calculated weight per metre (kg/m). Values are calculated using density = 7.93 g/cm³ and are for guidance — use actual MTC values for procurement & engineering.

| Size (mm) | Thickness (mm) | Weight per Meter (kg/m) | Approx. Weight per 6 Meter (kg) |

|---|---|---|---|

| 25 x 25 | 3 | 1.10 | 6.60 |

| 40 x 40 | 4 | 2.40 | 14.40 |

| 50 x 50 | 5 | 3.70 | 22.20 |

| 65 x 65 | 6 | 5.60 | 33.60 |

| 75 x 75 | 6 | 6.50 | 39.00 |

| 90 x 90 | 8 | 9.40 | 56.40 |

| 100 x 100 | 8 | 10.50 | 63.00 |

| 125 x 75 | 8 | 9.00 | 54.00 |

| 150 x 75 | 10 | 12.50 | 75.00 |

| 150 x 150 | 10 | 16.20 | 97.20 |

| 200 x 100 | 12 | 19.80 | 118.80 |

| 200 x 200 | 12 | 24.00 | 144.00 |

Types Of SS XM 19 Angal channel

Stainless Steel Angal & channel

Monel 400 Angal & channel

Inconel 600 Angal & channel

Hastelloy Angal & channel

Super Duplex Angal & channel

Duplex Angal & channel

Nickel Angal & channel

Monel K500 Angal & channel

Frequently Asked Questions (FAQ)

What is SS XM-19 (Nitronic 50) Stainless Steel Angle Channel?

SS XM-19, also known as Nitronic 50, is a high-strength austenitic stainless steel angle channel known for excellent corrosion resistance and superior mechanical properties. It offers twice the yield strength of 316 stainless steel and maintains toughness at both low and high temperatures.

What are the key features of Nitronic 50 Angle Channel?

The key features include outstanding resistance to pitting, crevice corrosion, and stress-corrosion cracking. It provides superior strength without the need for heat treatment and has excellent weldability, formability, and galling resistance, making it ideal for marine and chemical applications.

Where is SS XM-19 Angle Channel commonly used?

SS XM-19 Angle Channels are used in marine hardware, pump and valve components, chemical process equipment, fasteners, and structural parts exposed to seawater or harsh chemical environments. It is also suitable for offshore and desalination plant structures.

How does Nitronic 50 compare with SS 316 and SS 304?

Nitronic 50 offers nearly double the yield strength of SS 316 and SS 304 while providing superior corrosion resistance, especially in chloride and marine environments. It also resists galling and wear better than conventional stainless steels.

Can SS XM-19 Angle Channel be welded and machined easily?

Yes, XM-19 can be welded using standard stainless-steel welding techniques with matching filler materials. It machines somewhat harder than 304/316 due to its higher strength and nitrogen content, so proper tooling and lubrication are recommended during machining.

Angle Channels Supplier

Mumbai, Delhi, Kolkata, Chennai, Bengaluru, Hyderabad, Ahmadabad, Pune, Surat, Jaipur, Kanpur, Lucknow, Nagpur, Ghaziabad, Indore, Coimbatore, Kochi, Patna, Kozhikode, Thrissur, Vadodara, Agra, Malappuram, Thiruvananthapuram, Kannur, Ludhiana, Nashik, Noida, Madrid, Sharjah, Moscow, Hong Kong, Lagos, Montreal, Bogota, Los Angeles, New Delhi, Jeddah, Chennai, Kanpur, Edmonton, Istanbul, Bhopal, Calgary, Ulsan, Rio de Janeiro, Colombo, Cairo, Ludhiana, Indore, Thane, Dubai, Seoul, Santiago, Kuwait City, Dammam, Tehran, Busan, Rajkot, Nagpur, La Victoria, Bangkok, Granada, Lahore, Manama

Angle Channels Exporter

SS XM-19 (Nitronic50) Angle Channel exporter South Korea, SS XM-19 (Nitronic50) Angle Channel exporter in South Africa, SS XM-19 (Nitronic50) Angle Channel exporter in Sri Lanka, SS XM-19 (Nitronic50) Angle Channel exporter in Syria, SS XM-19 (Nitronic50) Angle Channel exporter in Taiwan, SS XM-19 (Nitronic50) Angle Channel exporter in Tanzania, SS XM-19 (Nitronic50) Angle Channel exporter in Tajikistan, SS XM-19 (Nitronic50) Angle Channel exporter in Thailand, SS XM-19 (Nitronic50) Angle Channel exporter in Turkey, SS XM-19 (Nitronic50) Angle Channel exporter in Turkmenistan, SS XM-19 (Nitronic50) Angle Channel exporter in Ukraine, SS XM-19 (Nitronic50) Angle Channel exporter in United Kingdom, SS XM-19 (Nitronic50) Angle Channel exporter in United Arab Emirates (UAE), SS XM-19 (Nitronic50) Angle Channel exporter in Uzbekistan, SS XM-19 (Nitronic50) Angle Channel exporter in Vietnam, SS XM-19 (Nitronic50) Angle Channel exporter in Yemen, SS XM-19 (Nitronic50) Angle Channel exporter in France, SS XM-19 (Nitronic50) Angle Channel exporter in Germany, SS XM-19 (Nitronic50) Angle Channel exporter in Greece, SS XM-19 (Nitronic50) Angle Channel exporter in Oman, SS XM-19 (Nitronic50) Angle Channel exporter in Colombia, SS XM-19 (Nitronic50) Angle Channel exporter in Portugal, SS XM-19 (Nitronic50) Angle Channel exporter in Japan, SS XM-19 (Nitronic50) Angle Channel exporter in Lithuania, SS XM-19 (Nitronic50) Angle Channel exporter in Macau, SS XM-19 (Nitronic50) Angle Channel exporter in Mongolia, SS XM-19 (Nitronic50) Angle Channel exporter in Qatar, SS XM-19 (Nitronic50) Angle Channel exporter in Ireland, SS XM-19 (Nitronic50) Angle Channel exporter in Malaysia, SS XM-19 (Nitronic50) Angle Channel exporter in Bangladesh, SS XM-19 (Nitronic50) Angle Channel exporter in United Kingdom, SS XM-19 (Nitronic50) Angle Channel exporter in Russia, SS XM-19 (Nitronic50) Angle Channel exporter in Iran, SS XM-19 (Nitronic50) Angle Channel exporter in Vietnam, SS XM-19 (Nitronic50) Angle Channel exporter in Jordan, SS XM-19 (Nitronic50) Angle Channel exporter in Yemen, SS XM-19 (Nitronic50) Angle Channel exporter in South Africa, SS XM-19 (Nitronic50) Angle Channel exporter in Singapore, SS XM-19 (Nitronic50) Angle Channel exporter in Sri Lanka, SS XM-19 (Nitronic50) Angle Channel exporter in Thailand, SS XM-19 (Nitronic50) Angle Channel exporter in Bulgaria, SS XM-19 (Nitronic50) Angle Channel exporter in Poland, SS XM-19 (Nitronic50) Angle Channel exporter in Denmark, SS XM-19 (Nitronic50) Angle Channel exporter in Nigeria, SS XM-19 (Nitronic50) Angle Channel exporter in Gambia, SS XM-19 (Nitronic50) Angle Channel exporter in Indonesia, SS XM-19 (Nitronic50) Angle Channel exporter in Finland, SS XM-19 (Nitronic50) Angle Channel exporter in Argentina, SS XM-19 (Nitronic50) Angle Channel exporter in Chile, SS XM-19 (Nitronic50) Angle Channel exporter in Spain, SS XM-19 (Nitronic50) Angle Channel exporter in Peru, SS XM-19 (Nitronic50) Angle Channel exporter in Kuwait, SS XM-19 (Nitronic50) Angle Channel exporter in India, SS XM-19 (Nitronic50) Angle Channel exporter in Saudi Arabia, SS XM-19 (Nitronic50) Angle Channel exporter in Slovakia, SS XM-19 (Nitronic50) Angle Channel exporter in Slovenia, SS XM-19 (Nitronic50) Angle Channel exporter in Spain, SS XM-19 (Nitronic50) Angle Channel exporter in Sweden, SS XM-19 (Nitronic50) Angle Channel exporter in Switzerland, SS XM-19 (Nitronic50) Angle Channel exporter in Singapore

People Also Search For

SS Sheets Supplier India, SS Coils Supplier India, SS 304 coil price list, SS 304 cold rolled coil distributors, SS 304 profile dealers, SS 304 circle price list, SS 304 coil exporter in mumbai, ss 304 coil Supplier in India, SS 304 coil exporter in india, SS 304 coil-circle exporter in mumbai, ss 304 blank suppliers, SS 304 coils price, ss 304 circle price list, astm a240 ss 304 circles exporter, ss 304 shim coils, SS 304 coil supplier in mumbai, SS Plates Supplier India, , ss 304 coil cheap price, high quality ss 304 coils stockholder in mumbai india.