Tantalum Shims Manufacturers in India, Tantalum Shimss Price, SS 2 Price per kg, Tantalum Shims 2 suppliers, Tantalum Shimss Price, Tantalum Shims Suppliers in UAE, Tantalum Shims Suppliers UK, Tantalum Shims Suppliers in Saudi Arabia, Tantalum Shims Suppliers in Qatar, Tantalum Shims Suppliers Australia.

Titanium Grade 2 is widely used in aerospace and chemical industries due to its corrosion resistance. Its high strength-to-weight ratio makes it suitable for lightweight structures. It can be easily welded and formed into tubes, sheets, and plates. Maintenance is minimal because of its natural oxide layer. Engineers favor it for critical applications requiring reliability.

Duplex Steel S31803 combines ferritic and austenitic properties, offering high strength and excellent corrosion resistance. It is often used in chemical plants and offshore structures. Fabrication requires controlled welding procedures. The steel performs well under chloride-rich environments. Regular inspection ensures long-term performance.

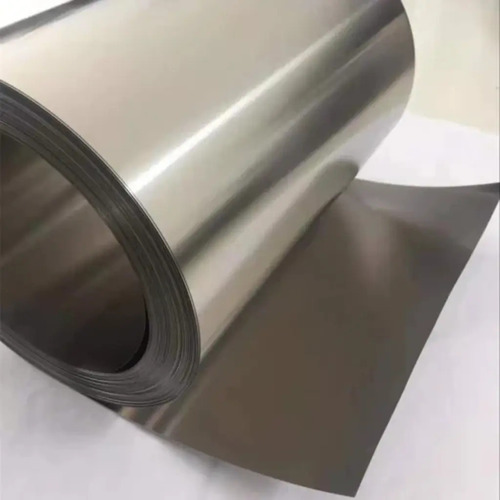

Tantalum Shims are ideal for high-temperature applications where other metals may deform. They resist oxidation and chemical attack even in aggressive environments. These shims provide low friction surfaces, making them suitable for mechanical assemblies. Their strength allows repeated use without wear. Tantalum Shims are commonly used in valves, pumps, and electronic components.

The versatility of Tantalum Shims makes them indispensable in precision engineering. They are used to maintain spacing and alignment in machinery. Resistant to acids, alkalis, and other corrosive substances, Tantalum Shims last longer than many metal alternatives. Their lightweight nature simplifies handling during installation. They are widely applied in chemical reactors and laboratory equipment.

Tantalum Shims offer excellent thermal conductivity along with corrosion resistance. This makes them suitable for high-heat environments such as heat exchangers and turbines. Their dimensional stability ensures machinery operates efficiently. The shims are resistant to mechanical deformation under stress. Tantalum Shims are ideal for both industrial and electronic applications.

In electronic and semiconductor industries, Tantalum Shims are used for insulation and alignment. They provide chemical resistance and low friction, enhancing the durability of sensitive components. Lightweight and easy to install, these shims maintain precision over time. Tantalum Shims are resistant to wear and thermal cycling. Their reliability reduces maintenance needs in critical applications.

Tantalum Shims are favored in chemical processing plants due to their resistance to aggressive chemicals. They maintain structural integrity even under high temperatures and pressure. These shims are used to align piping, valves, and pumps accurately. Their durability ensures long-term performance without degradation. Tantalum Shims are essential for industries where corrosion resistance is critical.

Specification Table

| Specification | Details |

|---|---|

| Product Name | Tantalum Shims |

| Standard | ASTM B708 / ASME SB708 |

| Grades | R05200, R05400 (Tantalum, Tantalum Alloy) |

| Thickness | 0.01 mm to 5 mm (Custom sizes available) |

| Width | Up to 1000 mm |

| Length | Up to 2000 mm or as per requirement |

| Finish | Bright, Matte, Polished |

| Form | Shims, Sheets, Foils, Strips |

| Melting Point | 2996°C |

| Density | 16.6 g/cm³ |

| Applications | Aerospace, Chemical Processing, Electronics, Medical Equipment |

Chemical Composition (Typical ranges for SSGrade)

Note: Values are typical ranges. Final composition will be confirmed on MTC provided per lot.

| Element | Symbol | Composition (%) |

|---|---|---|

| Tantalum | Ta | ≥ 99.9 |

| Oxygen | O | ≤ 0.01 |

| Carbon | C | ≤ 0.01 |

| Nitrogen | N | ≤ 0.01 |

| Hydrogen | H | ≤ 0.001 |

| Niobium | Nb | ≤ 0.1 |

| Iron | Fe | ≤ 0.005 |

| Silicon | Si | ≤ 0.005 |

| Tungsten | W | ≤ 0.05 |

Mechanical Properties (Typical)

| Property | Metric Value | Imperial Value |

|---|---|---|

| Tensile Strength | 200 – 400 MPa | 29 – 58 ksi |

| Yield Strength (0.2% Offset) | 170 – 350 MPa | 25 – 51 ksi |

| Elongation at Break | ≥ 30% | ≥ 30% |

| Hardness (Vickers) | 120 – 140 HV | 120 – 140 HV |

| Modulus of Elasticity | 186 GPa | 27 x 10⁶ psi |

| Melting Point | 2996°C | 5425°F |

| Density | 16.6 g/cm³ | 0.60 lb/in³ |

Equivalent Grades

| Standard | Grade | Description |

|---|---|---|

| ASTM | B708 R05200 | Unalloyed Tantalum (Electron Beam or Vacuum Arc Melted) |

| ASTM | B708 R05400 | Unalloyed Tantalum (Electron Beam or Vacuum Arc Remelted) |

| UNS | R05200 | Commercially Pure Tantalum |

| UNS | R05400 | High Purity Tantalum |

| ISO | Ta 99.9 | Equivalent to ASTM B708 R05200 |

| DIN | 3.10 | German Standard for Pure Tantalum |

Dimension & Weight Chart (Selected common sizes)

Below is a representative chart showing outside diameter, wall thickness, inside diameter, cross-sectional area of metal and calculated weight per metre (kg/m). Values are calculated using density = 7.93 g/cm³ and are for guidance — use actual MTC values for procurement & engineering.

| Thickness (mm) | Width (mm) | Length (mm) | Approx. Weight (kg/m²) |

|---|---|---|---|

| 0.05 | Up to 1000 | Up to 2000 | 0.83 |

| 0.10 | Up to 1000 | Up to 2000 | 1.66 |

| 0.25 | Up to 1000 | Up to 2000 | 4.15 |

| 0.50 | Up to 1000 | Up to 2000 | 8.30 |

| 1.00 | Up to 1000 | Up to 2000 | 16.60 |

| 2.00 | Up to 1000 | Up to 2000 | 33.20 |

| 3.00 | Up to 1000 | Up to 2000 | 49.80 |

| 4.00 | Up to 1000 | Up to 2000 | 66.40 |

| 5.00 | Up to 1000 | Up to 2000 | 83.00 |

Types Of Tantalum Shims

Stainless Steel Shims

Monel 400 Steel Shims

Hastelloy Shims

Nickel Shims

Super Duplex Shims

Duplex Shims

Inconel 600 Shims

Monel K500 Shims

Frequently Asked Questions (FAQ)

What are Tantalum Shims?

Tantalum Shims are thin sheets or strips made from high-purity tantalum metal, used for precision alignment, spacing, and insulation in high-performance industrial applications. They offer excellent corrosion resistance, high melting point, and mechanical strength.

What standards are Tantalum Shims manufactured to?

Tantalum Shims are typically manufactured in accordance with ASTM B708 / ASME SB708 standards, ensuring high purity and consistency. Common grades include R05200 and R05400.

What are the main applications of Tantalum Shims?

Tantalum Shims are used in aerospace, chemical processing, medical, and electronic industries. They are commonly applied in heat exchangers, reactor linings, laboratory instruments, and precision components where corrosion resistance is critical.

What is the temperature resistance of Tantalum Shims?

Tantalum Shims can withstand extremely high temperatures up to 2996°C. They maintain mechanical stability and strength even under intense thermal and corrosive conditions.

Can Tantalum Shims be customized in size and thickness?

Yes. Tantalum Shims can be custom manufactured to specific dimensions, thicknesses, and finishes according to client requirements. Custom-cut options are available for specialized applications.

Tantalum Shim Supplier

Mumbai, Delhi, Kolkata, Chennai, Bengaluru, Hyderabad, Ahmadabad, Pune, Surat, Jaipur, Kanpur, Lucknow, Nagpur, Ghaziabad, Indore, Coimbatore, Kochi, Patna, Kozhikode, Thrissur, Vadodara, Agra, Malappuram, Thiruvananthapuram, Kannur, Ludhiana, Nashik, Noida, Madrid, Sharjah, Moscow, Hong Kong, Lagos, Montreal, Bogota, Los Angeles, New Delhi, Jeddah, Chennai, Kanpur, Edmonton, Istanbul, Bhopal, Calgary, Ulsan, Rio de Janeiro, Colombo, Cairo, Ludhiana, Indore, Thane, Dubai, Seoul, Santiago, Kuwait City, Dammam, Tehran, Busan, Rajkot, Nagpur, La Victoria, Bangkok, Granada, Lahore, Manama

Tantalum Shim Exporter

Tantalum Shims exporter South Korea, Tantalum Shims exporter in South Africa, Tantalum Shims exporter in Sri Lanka, Tantalum Shims exporter in Syria, Tantalum Shims exporter in Taiwan, Tantalum Shims exporter in Tanzania, Tantalum Shims exporter in Tajikistan, Tantalum Shims exporter in Thailand, Tantalum Shims exporter in Turkey, Tantalum Shims exporter in Turkmenistan, Tantalum Shims exporter in Ukraine, Tantalum Shims exporter in United Kingdom, Tantalum Shims exporter in United Arab Emirates (UAE), Tantalum Shims exporter in Uzbekistan, Tantalum Shims exporter in Vietnam, Tantalum Shims exporter in Yemen, Tantalum Shims exporter in France, Tantalum Shims exporter in Germany, Tantalum Shims exporter in Greece, Tantalum Shims exporter in Oman, Tantalum Shims exporter in Colombia, Tantalum Shims exporter in Portugal, Tantalum Shims exporter in Japan, Tantalum Shims exporter in Lithuania, Tantalum Shims exporter in Macau, Tantalum Shims exporter in Mongolia, Tantalum Shims exporter in Qatar, Tantalum Shims exporter in Ireland, Tantalum Shims exporter in Malaysia, Tantalum Shims exporter in Bangladesh, Tantalum Shims exporter in United Kingdom, Tantalum Shims exporter in Russia, Tantalum Shims exporter in Iran, Tantalum Shims exporter in Vietnam, Tantalum Shims exporter in Jordan, Tantalum Shims exporter in Yemen, Tantalum Shims exporter in South Africa, Tantalum Shims exporter in Singapore, Tantalum Shims exporter in Sri Lanka, Tantalum Shims exporter in Thailand, Tantalum Shims exporter in Bulgaria, Tantalum Shims exporter in Poland, Tantalum Shims exporter in Denmark, Tantalum Shims exporter in Nigeria, Tantalum Shims exporter in Gambia, Tantalum Shims exporter in Indonesia, Tantalum Shims exporter in Finland, Tantalum Shims exporter in Argentina, Tantalum Shims exporter in Chile, Tantalum Shims exporter in Spain, Tantalum Shims exporter in Peru, Tantalum Shims exporter in Kuwait, Tantalum Shims exporter in India, Tantalum Shims exporter in Saudi Arabia, Tantalum Shims exporter in Slovakia, Tantalum Shims exporter in Slovenia, Tantalum Shims exporter in Spain, Tantalum Shims exporter in Sweden, Tantalum Shims exporter in Switzerland, Tantalum Shims exporter in Singapore

People Also Search For

Titanium Sheets Supplier India, Titanium Coils Supplier India, SS 304 coil price list, Titanium 304 cold rolled coil distributors, Titanium 304 profile dealers, Titanium 304 circle price list, Titanium 304 coil exporter in mumbai, ss 304 coil Supplier in India, Titanium 304 coil exporter in india, Titanium 304 coil-circle exporter in mumbai, ss 304 blank suppliers, Titanium 304 coils price, ss 304 circle price list, astm a240 ss 304 circles exporter, ss 304 shim coils, Titanium 304 coil supplier in mumbai, Titanium Plates Supplier India, , ss 304 coil cheap price, high quality ss 304 coils stockholder in mumbai india.