Titanium Grade 12 Angle Channel Manufacturers in India, Titanium Grade 12 Angle Channels Price, SS 2062 Price per kg, Titanium Grade 12 Angle Channel 2062 suppliers, Titanium Grade 12 Angle Channels Price, Titanium Grade 12 Angle Channel Suppliers in UAE, Titanium Grade 12 Angle Channel Suppliers UK, Titanium Grade 12 Angle Channel Suppliers in Saudi Arabia, Titanium Grade 12 Angle Channel Suppliers in Qatar, Titanium Grade 12 Angle Channel Suppliers Australia.

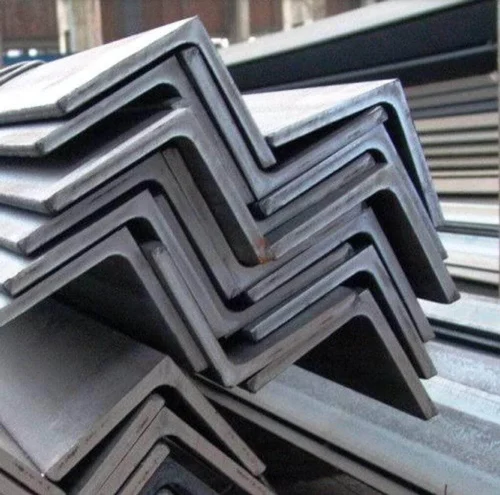

Titanium Grade 12 is a commercially important titanium alloy used where a balance of corrosion resistance, formability and weldability is required. Angle and channel profiles made from Grade 12 provide structural support while maintaining low weight and excellent durability in aggressive environments. These sections are widely used in marine equipment, chemical processing lines, and specialist architectural installations. Fabricators favour Grade 12 for its predictable performance during welding and post-weld treatments. Standard lengths and custom cut-to-size options are typically available from stock. Surface finishes range from mill finish to pickled and passivated, depending on the application.

Typical applications for Grade 12 angle and channel include seawater handling systems, heat exchangers, pipe supports, brackets and corrosive-service framing. The alloy’s resistance to chloride stress corrosion cracking and many reducing and oxidizing environments makes it a smart choice for long-life installations. It combines useful strength with good ductility, allowing bending and forming into finished assemblies. Where weight reduction is important, titanium sections outperform many steel alternatives on specific-strength. Designers often choose Grade 12 when welding to dissimilar metals or where post-fabrication passivation is required. Maintenance requirements are minimal compared with coated steels in corrosive settings.

Material handling and fabrication notes for angle and channel sections emphasise careful cleaning before welding, control of heat input, and selection of compatible filler metals where needed. Machining Grade 12 is generally straightforward using sharp tooling and conservative feeds; coolant and chip control improve surface finish. For welding, inert gas shielding and qualified procedures produce consistent joints with low contamination risk. When specifying surface finish, consider whether additional pickling or electropolishing will be required for sanitary or aesthetic purposes. Protective packaging helps avoid contamination during shipment and storage. Always consult supplier datasheets for recommended fabrication guidelines and mechanical values.

Dimensional availability for angles and channels typically covers a wide range of leg lengths, thicknesses and radii — from light-duty brackets to heavy structural members. Custom roll-formed or extruded profiles can be produced for unique projects, and many stock sizes are offered in both cut-lengths and full bars. Weight-per-metre charts and section modulus tables are commonly provided to assist structural calculations. Corrosion allowances should be considered in long-term exposed installations, particularly in abrasive flows. For finished assemblies, fastener compatibility and galvanic considerations are important when joining to dissimilar metals; suitable isolation or compatible fasteners mitigate galvanic risk.

Surface treatment options for Grade 12 angles and channels include mill, annealed, pickled, and passivated states. Pickling and passivation restore the natural oxide and improve aesthetic uniformity for visible structures. Where hygienic or food-contact requirements exist, additional electropolishing can be specified to reduce surface roughness and microbial adhesion. Painting or coating is rarely necessary for corrosion protection, but may be applied for appearance or thermal/insulative needs using appropriate surface-prep methods. Labeling and traceability are provided by reputable suppliers to support QA and regulatory compliance. Keep documentation for heat numbers, mill test certificates and finish instructions with the job pack.

Purchasing tips: request certified mill test reports, confirm dimensional tolerances and surface finish, and ask about stock lead times for non-standard sizes. When performance in chloride-bearing or marine environments is required, confirm the specific qualification of Grade 12 for the intended service. Consider ordering slightly larger sections if in-service corrosion allowance or future modifications are likely. Obtain guidance on welding consumables and approved procedures if in-house fabrication is planned. For critical structural uses, request mechanical property ranges at the specified temper or condition. Reliable suppliers will advise on storage, handling and recommended inspection checkpoints.

Key benefits of Titanium Grade 12 angles and channels are corrosion resistance, good weldability, low density, and long service life in aggressive environments. Limitations to consider include higher material cost versus common carbon steels and the need for knowledgeable fabrication practices to achieve optimal results. For many long-term or high-performance installations the life-cycle cost favours titanium despite higher upfront price. Engineers often pair Grade 12 with appropriate design detailing and fastener selection to maximise durability while minimising maintenance. When specified correctly, Grade 12 angle and channel sections deliver a reliable, lightweight structural solution across marine, chemical and specialty industrial sectors.

Specification Table

| Specification | Details |

|---|---|

| Standard | ASTM B265 / ASME SB265, ASTM B338, ASTM B348, AMS 4907 |

| Grade | Titanium Grade 12 (Ti-0.3Mo-0.8Ni) |

| Form | Angle, Channel, Flat, Round, Sheet, Plate |

| Size Range | Angles: 20 mm × 20 mm × 3 mm up to 100 mm × 100 mm × 10 mm Channels: C 25 × 13 × 3 mm up to C 200 × 75 × 10 mm |

| Condition | Annealed / Pickled / Mill Finish / Polished |

| Manufacturing Process | Hot Rolled / Cold Rolled / Extruded |

| Density | 4.51 g/cm³ |

| Melting Point | 1660 °C (3020 °F) |

| Modulus of Elasticity | 105 GPa |

| Corrosion Resistance | Excellent in oxidizing and reducing environments, seawater, and chloride media |

| Applications | Marine, Chemical Processing, Heat Exchangers, Aerospace, Architectural |

Chemical Composition (Typical ranges for SSIS)

Note: Values are typical ranges. Final composition will be confirmed on MTC provided per lot.

| Element | Percentage (%) |

|---|---|

| Titanium (Ti) | Balance |

| Nickel (Ni) | 0.6 – 0.9 |

| Molybdenum (Mo) | 0.2 – 0.4 |

| Iron (Fe) | ≤ 0.30 |

| Carbon (C) | ≤ 0.08 |

| Oxygen (O) | ≤ 0.25 |

| Nitrogen (N) | ≤ 0.03 |

| Hydrogen (H) | ≤ 0.015 |

Mechanical Properties (Typical)

| Property | Metric Value | Imperial Value |

|---|---|---|

| Tensile Strength (Minimum) | 483 MPa | 70,000 psi |

| Yield Strength (0.2% Offset) | 345 MPa | 50,000 psi |

| Elongation at Break | 18% | 18% |

| Modulus of Elasticity | 105 GPa | 15.2 × 106 psi |

| Hardness (Rockwell B) | 70 HRB (approx.) | 70 HRB (approx.) |

| Density | 4.51 g/cm³ | 0.163 lb/in³ |

| Melting Point | 1660 °C | 3020 °F |

| Poisson’s Ratio | 0.34 | 0.34 |

Equivalent Grades

| Standard | Equivalent Grade | Description |

|---|---|---|

| UNS | R53400 | Unified Numbering System designation for Titanium Grade 12 |

| ASTM | Grade 12 (ASTM B265 / B348) | Commercial titanium alloy with Mo and Ni for enhanced corrosion resistance |

| ASME | SB-265 Grade 12 | Standard specification for titanium and titanium alloy plates and sheets |

| AMS | AMS 4907 | Aerospace specification for Titanium Grade 12 sheet and plate |

| ISO | Ti-0.3Mo-0.8Ni | International equivalent composition designation |

| BS | 3252-Grade 3.7115 | British Standard equivalent for Titanium Grade 12 |

| JIS | Type 12 | Japanese Industrial Standard designation for Ti Grade 12 |

Dimension & Weight Chart (Selected common sizes)

Below is a representative chart showing outside diameter, wall thickness, inside diameter, cross-sectional area of metal and calculated weight per metre (kg/m). Values are calculated using density = 7.93 g/cm³ and are for guidance — use actual MTC values for procurement & engineering.

| Size (mm) | Thickness (mm) | Leg Length (mm) | Approx. Weight (kg/m) | Section Type |

|---|---|---|---|---|

| 20 × 20 | 3 | 20 | 0.37 | Angle |

| 25 × 25 | 3 | 25 | 0.47 | Angle |

| 40 × 40 | 4 | 40 | 1.03 | Angle |

| 50 × 50 | 5 | 50 | 1.70 | Angle |

| 65 × 65 | 6 | 65 | 2.63 | Angle |

| 75 × 75 | 6 | 75 | 3.06 | Angle |

| 100 × 100 | 10 | 100 | 5.95 | Angle |

| C 50 × 25 | 4 | 25 | 2.05 | Channel |

| C 75 × 40 | 5 | 40 | 3.10 | Channel |

| C 100 × 50 | 6 | 50 | 4.80 | Channel |

| C 150 × 65 | 8 | 65 | 7.65 | Channel |

| C 200 × 75 | 10 | 75 | 10.95 | Channel |

Types Of Titanium Grade 12 Angal channel

Stainless Steel Angal & channel

Monel 400 Angal & channel

Inconel 600 Angal & channel

Titanium Grade Angal & channel

Super Duplex Angal & channel

Duplex Angal & channel

Nickel Angal & channel

Monel K500 Angal & channel

Frequently Asked Questions (FAQ)

What is Titanium Grade 12 and how does it differ from commercially pure titanium?

Titanium Grade 12 (UNS R53400) is an alloyed titanium (typically Ti-0.3Mo-0.8Ni) that offers improved corrosion resistance and strength compared with commercially pure grades (Grade 1–4). The small additions of molybdenum and nickel enhance performance in chloride-containing and crevice-corrosion environments while retaining good weldability.

What typical forms are available for Grade 12 angle and channel?

Common forms include hot-rolled or extruded angles and channels in cut lengths, full bars, and occasionally custom extrusions. Finishes offered are mill, annealed, pickled and passivated, or polished on request.

What are common applications for Grade 12 angles and channels?

Typical applications include seawater systems, heat exchangers, chemical processing structures, pipe supports, marine hardware, and architectural elements requiring long-term corrosion resistance and reduced weight.

Is Grade 12 weldable and what welding precautions should be followed?

Yes — Grade 12 is readily weldable using standard inert-gas welding procedures. Use qualified procedures, proper filler metals where required, clean joint preparation, and adequate inert shielding to avoid contamination. Post-weld pickling/passivation may be specified for critical corrosion performance or appearance.

How does Grade 12 perform in seawater and chloride environments?

Grade 12 exhibits excellent resistance to corrosion in seawater and many chloride-bearing environments, performing significantly better than many stainless steels. However, design details (crevices, fasteners, dissimilar metal contact) should be considered.

Angle Channels Supplier

Mumbai, Delhi, Kolkata, Chennai, Bengaluru, Hyderabad, Ahmadabad, Pune, Surat, Jaipur, Kanpur, Lucknow, Nagpur, Ghaziabad, Indore, Coimbatore, Kochi, Patna, Kozhikode, Thrissur, Vadodara, Agra, Malappuram, Thiruvananthapuram, Kannur, Ludhiana, Nashik, Noida, Madrid, Sharjah, Moscow, Hong Kong, Lagos, Montreal, Bogota, Los Angeles, New Delhi, Jeddah, Chennai, Kanpur, Edmonton, Istanbul, Bhopal, Calgary, Ulsan, Rio de Janeiro, Colombo, Cairo, Ludhiana, Indore, Thane, Dubai, Seoul, Santiago, Kuwait City, Dammam, Tehran, Busan, Rajkot, Nagpur, La Victoria, Bangkok, Granada, Lahore, Manama

Angle Channels Exporter

Titanium Grade 12 Angle Channel exporter South Korea, Titanium Grade 12 Angle Channel exporter in South Africa, Titanium Grade 12 Angle Channel exporter in Sri Lanka, Titanium Grade 12 Angle Channel exporter in Syria, Titanium Grade 12 Angle Channel exporter in Taiwan, Titanium Grade 12 Angle Channel exporter in Tanzania, Titanium Grade 12 Angle Channel exporter in Tajikistan, Titanium Grade 12 Angle Channel exporter in Thailand, Titanium Grade 12 Angle Channel exporter in Turkey, Titanium Grade 12 Angle Channel exporter in Turkmenistan, Titanium Grade 12 Angle Channel exporter in Ukraine, Titanium Grade 12 Angle Channel exporter in United Kingdom, Titanium Grade 12 Angle Channel exporter in United Arab Emirates (UAE), Titanium Grade 12 Angle Channel exporter in Uzbekistan, Titanium Grade 12 Angle Channel exporter in Vietnam, Titanium Grade 12 Angle Channel exporter in Yemen, Titanium Grade 12 Angle Channel exporter in France, Titanium Grade 12 Angle Channel exporter in Germany, Titanium Grade 12 Angle Channel exporter in Greece, Titanium Grade 12 Angle Channel exporter in Oman, Titanium Grade 12 Angle Channel exporter in Colombia, Titanium Grade 12 Angle Channel exporter in Portugal, Titanium Grade 12 Angle Channel exporter in Japan, Titanium Grade 12 Angle Channel exporter in Lithuania, Titanium Grade 12 Angle Channel exporter in Macau, Titanium Grade 12 Angle Channel exporter in Mongolia, Titanium Grade 12 Angle Channel exporter in Qatar, Titanium Grade 12 Angle Channel exporter in Ireland, Titanium Grade 12 Angle Channel exporter in Malaysia, Titanium Grade 12 Angle Channel exporter in Bangladesh, Titanium Grade 12 Angle Channel exporter in United Kingdom, Titanium Grade 12 Angle Channel exporter in Russia, Titanium Grade 12 Angle Channel exporter in Iran, Titanium Grade 12 Angle Channel exporter in Vietnam, Titanium Grade 12 Angle Channel exporter in Jordan, Titanium Grade 12 Angle Channel exporter in Yemen, Titanium Grade 12 Angle Channel exporter in South Africa, Titanium Grade 12 Angle Channel exporter in Singapore, Titanium Grade 12 Angle Channel exporter in Sri Lanka, Titanium Grade 12 Angle Channel exporter in Thailand, Titanium Grade 12 Angle Channel exporter in Bulgaria, Titanium Grade 12 Angle Channel exporter in Poland, Titanium Grade 12 Angle Channel exporter in Denmark, Titanium Grade 12 Angle Channel exporter in Nigeria, Titanium Grade 12 Angle Channel exporter in Gambia, Titanium Grade 12 Angle Channel exporter in Indonesia, Titanium Grade 12 Angle Channel exporter in Finland, Titanium Grade 12 Angle Channel exporter in Argentina, Titanium Grade 12 Angle Channel exporter in Chile, Titanium Grade 12 Angle Channel exporter in Spain, Titanium Grade 12 Angle Channel exporter in Peru, Titanium Grade 12 Angle Channel exporter in Kuwait, Titanium Grade 12 Angle Channel exporter in India, Titanium Grade 12 Angle Channel exporter in Saudi Arabia, Titanium Grade 12 Angle Channel exporter in Slovakia, Titanium Grade 12 Angle Channel exporter in Slovenia, Titanium Grade 12 Angle Channel exporter in Spain, Titanium Grade 12 Angle Channel exporter in Sweden, Titanium Grade 12 Angle Channel exporter in Switzerland, Titanium Grade 12 Angle Channel exporter in Singapore

People Also Search For

SS Sheets Supplier India, SS Coils Supplier India, SS 304 coil price list, SS 304 cold rolled coil distributors, SS 304 profile dealers, SS 304 circle price list, SS 304 coil exporter in mumbai, ss 304 coil Supplier in India, SS 304 coil exporter in india, SS 304 coil-circle exporter in mumbai, ss 304 blank suppliers, SS 304 coils price, ss 304 circle price list, astm a240 ss 304 circles exporter, ss 304 shim coils, SS 304 coil supplier in mumbai, SS Plates Supplier India, , ss 304 coil cheap price, high quality ss 304 coils stockholder in mumbai india.