Titanium Grade 2 Angle Channel Manufacturers in India, Titanium Grade 2 Angle Channels Price, SS 2062 Price per kg, Titanium Grade 2 Angle Channel 2062 suppliers, Titanium Grade 2 Angle Channels Price, Titanium Grade 2 Angle Channel Suppliers in UAE, Titanium Grade 2 Angle Channel Suppliers UK, Titanium Grade 2 Angle Channel Suppliers in Saudi Arabia, Titanium Grade 2 Angle Channel Suppliers in Qatar, Titanium Grade 2 Angle Channel Suppliers Australia.

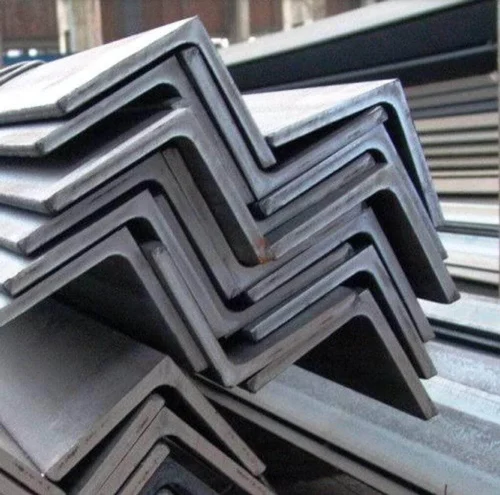

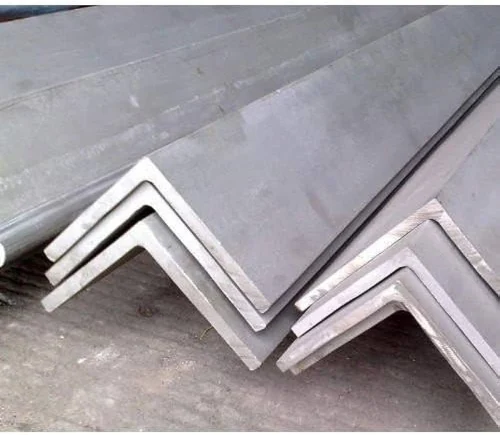

Titanium Grade 2 Angle & Channel are highly versatile structural components known for their exceptional strength-to-weight ratio, corrosion resistance, and excellent formability. These products are commonly used in applications where superior durability and low density are required. With outstanding weldability and ductility, Titanium Grade 2 Angles & Channels are preferred in chemical processing, marine, aerospace, and architectural industries. Their ability to withstand oxidizing and mildly reducing environments makes them ideal for long-term performance.

Titanium Grade 2, also known as commercially pure titanium, offers excellent mechanical properties combined with high corrosion resistance in oxidizing and chloride-containing environments. These Angles & Channels provide superior protection against seawater, saline solutions, and a wide range of acids. Due to their biocompatibility, they are also used in medical and pharmaceutical equipment manufacturing. The non-magnetic and non-toxic properties further enhance their usability in sensitive applications.

The Titanium Grade 2 Angle is widely used for structural framing and support purposes where light weight and superior corrosion resistance are essential. The Angle design allows for effective load distribution, making it suitable for marine construction, offshore platforms, and aerospace structures. Meanwhile, the Channel sections provide enhanced rigidity and support, especially in high-stress environments. Both shapes offer excellent resistance to fatigue and stress cracking.

Titanium Grade 2 Angles & Channels are produced through precision manufacturing processes such as hot rolling, cold rolling, or extrusion to meet diverse industrial standards. They are available in a wide range of dimensions, thicknesses, and surface finishes to match specific engineering needs. The surface finish can be polished, brushed, or mill-finished, depending on aesthetic or performance requirements. Custom fabrication and machining options are also available for specialized applications.

In the aerospace industry, Titanium Grade 2 Angles and Channels are used for airframes, engine components, and structural supports because of their lightweight nature and ability to resist high temperatures. In the marine industry, these sections serve as durable components in shipbuilding, underwater piping, and offshore oil platforms. Their resistance to saltwater corrosion ensures a long service life, even in the most challenging sea conditions.

Chemical processing industries utilize Titanium Grade 2 structural sections due to their resistance to strong oxidizers, chlorides, and acidic media. These Angles & Channels are often incorporated into heat exchangers, pressure vessels, storage tanks, and pipelines. Their ability to maintain strength and integrity in harsh chemical environments minimizes maintenance costs and ensures long operational life. This makes Titanium Grade 2 a cost-effective choice over the long term despite its higher initial investment.

Architectural and industrial designers value Titanium Grade 2 Angles & Channels for their aesthetic appeal and corrosion resistance. Their natural metallic sheen and resistance to discoloration make them suitable for modern building facades, bridges, and outdoor installations. They can withstand pollution, moisture, and temperature fluctuations, maintaining both appearance and performance for decades. In summary, Titanium Grade 2 Angles & Channels are a superior choice for industries demanding reliability, longevity, and lightweight strength.

Specification Table

| UNS / Grade | — | UNS R50400 (Grade 2) | Commercially pure titanium, moderate strength, excellent corrosion resistance |

| Chemical composition (Ti, min) | wt% | ≥ 99.2% Ti | Small amounts of O, N, C, Fe permitted (trace) |

| Density | g/cm³ | 4.51 | Lightweight compared to steels |

| Melting point | °C | ~1660–1670 | High melting point suitable for elevated-temperature uses |

| Young's modulus (Elastic modulus) | GPa | ~105 | Lower modulus than steels — more flexibility under load |

| Ultimate tensile strength (UTS) | MPa | ~340–450 | Depends on tempers and manufacturing (rolled/extruded) |

| Yield strength (0.2% offset) | MPa | ~275–360 | Typical for Grade 2 in common tempers |

| Elongation (A on 50 mm) | % | ~20–30 | Good ductility — easy to form/weld |

| Hardness (approx.) | HV / HB | ~120–170 HV (≈ 110–160 HB) | Varies with processing and cold work |

| Thermal conductivity | W/m·K | ~16–22 | Moderate thermal conductivity |

| Electrical resistivity | µΩ·m | ~0.42 | Non-ferrous, non-magnetic |

| Corrosion resistance | — | Excellent | Highly resistant in oxidizing and many chloride-containing environments (marine, chemical) |

| Available forms | — | Angles, Channels, Plates, Bars, Extrusions | Angles & Channels commonly hot-rolled or extruded; custom sections available |

| Typical angle/channel sizes (examples) | mm | Leg lengths: 10–200 mm • Thickness: 2–12 mm | Custom dimensions and heavier sections available on request |

| Surface finish | — | Mill, brushed, polished | Finish chosen per application and aesthetic requirements |

| Fabrication | — | Weldable, formable, machinable | Good weldability with appropriate filler and shielding gas |

| Typical standards & specs | — | Refer to manufacturer / project spec | Check purchase order/spec for exact certification requirements |

Chemical Composition (Typical ranges for SSIS)

Note: Values are typical ranges. Final composition will be confirmed on MTC provided per lot.

| Titanium | Ti | Balance (≥ 99.2%) | Primary element, provides strength and corrosion resistance |

| Iron | Fe | ≤ 0.30 | Minor impurity; controlled for ductility |

| Oxygen | O | ≤ 0.25 | Improves strength but reduces ductility at higher levels |

| Carbon | C | ≤ 0.08 | Maintained low to ensure good weldability and toughness |

| Nitrogen | N | ≤ 0.03 | Trace element; excess leads to embrittlement |

| Hydrogen | H | ≤ 0.015 | Controlled to prevent hydrogen embrittlement |

| Other Elements (each) | — | ≤ 0.10 | Combined trace impurities per ASTM standards |

| Total Impurities | — | ≤ 0.40 | Ensures high purity and performance consistency |

Mechanical Properties (Typical)

| Tensile Strength (Ultimate) | MPa | 340 – 450 | Varies based on product form and processing condition |

| Yield Strength (0.2% Offset) | MPa | 275 – 360 | Annealed condition; higher values possible with cold work |

| Elongation (in 50 mm) | % | 20 – 30 | Excellent ductility and formability |

| Reduction of Area | % | 25 – 35 | Good toughness under tensile loading |

| Hardness | HB / HV | 110 – 160 HB (≈120 – 170 HV) | Depends on heat treatment and work condition |

| Modulus of Elasticity | GPa | 105 | Lower than steel — allows flexibility and vibration resistance |

| Poisson’s Ratio | — | 0.34 | Typical for commercially pure titanium |

| Shear Modulus | GPa | 42 | Good strength-to-weight performance in shear loading |

| Impact Toughness (Charpy V-Notch) | J | ≥ 20 at room temperature | High impact resistance; suitable for dynamic loads |

| Melting Point | °C | 1660 – 1670 | Suitable for elevated temperature applications |

| Density | g/cm³ | 4.51 | About 60% the density of steel — lightweight structural option |

Equivalent Grades

| Standard | Grade / Designation | Description | Country / Organization |

|---|---|---|---|

| UNS | R50400 | Commercially Pure Titanium Grade 2 | Unified Numbering System (USA) |

| ASTM | Grade 2 | Standard titanium grade for general engineering applications | American Society for Testing and Materials |

| ISO | Ti-2 | Commercially pure titanium, moderate strength | International Organization for Standardization |

| BS | TA2 | Equivalent to ASTM Grade 2 titanium | British Standard |

| JIS | Type 2 (TAP340) | Pure titanium for general fabrication and welding | Japanese Industrial Standard |

| DIN | 3.7035 | CP Titanium Grade 2 (Werkstoffnummer) | German Standard |

| EN | Ti CP Grade 2 | Commercially pure titanium with moderate strength and high ductility | European Standard |

| AMS | AMS 4902 / AMS 4941 | Sheets, strips, bars, and seamless tubes | Aerospace Material Specification (SAE) |

Dimension & Weight Chart (Selected common sizes)

Below is a representative chart showing outside diameter, wall thickness, inside diameter, cross-sectional area of metal and calculated weight per metre (kg/m). Values are calculated using density = 7.93 g/cm³ and are for guidance — use actual MTC values for procurement & engineering.

| Section Type | Size (mm) | Thickness (mm) | Weight (kg/m) | Remarks / Applications |

|---|---|---|---|---|

| Angle (Equal) | 20 × 20 | 3 | 0.53 | Used in lightweight frameworks and supports |

| Angle (Equal) | 30 × 30 | 3 | 0.82 | Suitable for marine and architectural fittings |

| Angle (Equal) | 40 × 40 | 4 | 1.44 | Used in aerospace and chemical plant structures |

| Angle (Equal) | 50 × 50 | 5 | 2.25 | Ideal for framing and load-bearing assemblies |

| Angle (Equal) | 65 × 65 | 6 | 3.72 | Preferred for industrial fabrication and piping supports |

| Angle (Equal) | 75 × 75 | 6 | 4.30 | Used in heavy-duty marine or offshore structures |

| Angle (Equal) | 100 × 100 | 8 | 7.35 | Common for load-bearing frames and equipment mounts |

| Channel (C-Section) | 50 × 25 | 4 | 1.58 | Lightweight structural applications |

| Channel (C-Section) | 75 × 40 | 5 | 2.90 | Used in frameworks, marine brackets |

| Channel (C-Section) | 100 × 50 | 6 | 4.75 | Industrial and mechanical structure support |

| Channel (C-Section) | 125 × 65 | 6 | 5.95 | General engineering and aerospace structures |

| Channel (C-Section) | 150 × 75 | 8 | 8.60 | Used in heavy structural and marine frameworks |

| Channel (C-Section) | 200 × 100 | 10 | 13.40 | High-strength support systems and large assemblies |

Types Of Titanium Grade 2 Angal channel

Stainless Steel Angal & channel

Monel 400 Angal & channel

Inconel 600 Angal & channel

Titanium Grade Angal & channel

Super Duplex Angal & channel

Duplex Angal & channel

Nickel Angal & channel

Monel K500 Angal & channel

Frequently Asked Questions (FAQ)

What is Titanium Grade 2?

Titanium Grade 2, also known as UNS R50400, is a commercially pure titanium alloy that offers an excellent combination of strength, ductility, and corrosion resistance. It is widely used in marine, aerospace, chemical, and architectural industries for both structural and decorative applications.

What are the main advantages of Titanium Grade 2 Angles and Channels?

The main advantages include high corrosion resistance in oxidizing and marine environments, excellent weldability, lightweight nature, and good mechanical strength. These properties make Titanium Grade 2 Angles & Channels ideal for harsh environmental and high-performance applications.

Where are Titanium Grade 2 Angles & Channels commonly used?

They are used in aerospace structures, marine engineering, chemical processing plants, heat exchangers, and architectural projects. Their resistance to saltwater corrosion also makes them popular for offshore platforms, shipbuilding, and desalination plants.

Are Titanium Grade 2 Angles & Channels easy to weld and fabricate?

Yes. Titanium Grade 2 offers excellent weldability and formability. It can be welded using TIG (GTAW) or plasma arc welding with proper shielding gas protection. The alloy can also be easily machined and formed into custom profiles.

How does Titanium Grade 2 compare to other titanium grades?

Among commercially pure titanium grades, Grade 2 provides the best balance of strength, ductility, and corrosion resistance. It is stronger than Grade 1 but more formable than Grades 3 and 4, making it a versatile choice for general engineering use.

Angle Channels Supplier

Mumbai, Delhi, Kolkata, Chennai, Bengaluru, Hyderabad, Ahmadabad, Pune, Surat, Jaipur, Kanpur, Lucknow, Nagpur, Ghaziabad, Indore, Coimbatore, Kochi, Patna, Kozhikode, Thrissur, Vadodara, Agra, Malappuram, Thiruvananthapuram, Kannur, Ludhiana, Nashik, Noida, Madrid, Sharjah, Moscow, Hong Kong, Lagos, Montreal, Bogota, Los Angeles, New Delhi, Jeddah, Chennai, Kanpur, Edmonton, Istanbul, Bhopal, Calgary, Ulsan, Rio de Janeiro, Colombo, Cairo, Ludhiana, Indore, Thane, Dubai, Seoul, Santiago, Kuwait City, Dammam, Tehran, Busan, Rajkot, Nagpur, La Victoria, Bangkok, Granada, Lahore, Manama

Angle Channels Exporter

Titanium Grade 2 Angle Channel exporter South Korea, Titanium Grade 2 Angle Channel exporter in South Africa, Titanium Grade 2 Angle Channel exporter in Sri Lanka, Titanium Grade 2 Angle Channel exporter in Syria, Titanium Grade 2 Angle Channel exporter in Taiwan, Titanium Grade 2 Angle Channel exporter in Tanzania, Titanium Grade 2 Angle Channel exporter in Tajikistan, Titanium Grade 2 Angle Channel exporter in Thailand, Titanium Grade 2 Angle Channel exporter in Turkey, Titanium Grade 2 Angle Channel exporter in Turkmenistan, Titanium Grade 2 Angle Channel exporter in Ukraine, Titanium Grade 2 Angle Channel exporter in United Kingdom, Titanium Grade 2 Angle Channel exporter in United Arab Emirates (UAE), Titanium Grade 2 Angle Channel exporter in Uzbekistan, Titanium Grade 2 Angle Channel exporter in Vietnam, Titanium Grade 2 Angle Channel exporter in Yemen, Titanium Grade 2 Angle Channel exporter in France, Titanium Grade 2 Angle Channel exporter in Germany, Titanium Grade 2 Angle Channel exporter in Greece, Titanium Grade 2 Angle Channel exporter in Oman, Titanium Grade 2 Angle Channel exporter in Colombia, Titanium Grade 2 Angle Channel exporter in Portugal, Titanium Grade 2 Angle Channel exporter in Japan, Titanium Grade 2 Angle Channel exporter in Lithuania, Titanium Grade 2 Angle Channel exporter in Macau, Titanium Grade 2 Angle Channel exporter in Mongolia, Titanium Grade 2 Angle Channel exporter in Qatar, Titanium Grade 2 Angle Channel exporter in Ireland, Titanium Grade 2 Angle Channel exporter in Malaysia, Titanium Grade 2 Angle Channel exporter in Bangladesh, Titanium Grade 2 Angle Channel exporter in United Kingdom, Titanium Grade 2 Angle Channel exporter in Russia, Titanium Grade 2 Angle Channel exporter in Iran, Titanium Grade 2 Angle Channel exporter in Vietnam, Titanium Grade 2 Angle Channel exporter in Jordan, Titanium Grade 2 Angle Channel exporter in Yemen, Titanium Grade 2 Angle Channel exporter in South Africa, Titanium Grade 2 Angle Channel exporter in Singapore, Titanium Grade 2 Angle Channel exporter in Sri Lanka, Titanium Grade 2 Angle Channel exporter in Thailand, Titanium Grade 2 Angle Channel exporter in Bulgaria, Titanium Grade 2 Angle Channel exporter in Poland, Titanium Grade 2 Angle Channel exporter in Denmark, Titanium Grade 2 Angle Channel exporter in Nigeria, Titanium Grade 2 Angle Channel exporter in Gambia, Titanium Grade 2 Angle Channel exporter in Indonesia, Titanium Grade 2 Angle Channel exporter in Finland, Titanium Grade 2 Angle Channel exporter in Argentina, Titanium Grade 2 Angle Channel exporter in Chile, Titanium Grade 2 Angle Channel exporter in Spain, Titanium Grade 2 Angle Channel exporter in Peru, Titanium Grade 2 Angle Channel exporter in Kuwait, Titanium Grade 2 Angle Channel exporter in India, Titanium Grade 2 Angle Channel exporter in Saudi Arabia, Titanium Grade 2 Angle Channel exporter in Slovakia, Titanium Grade 2 Angle Channel exporter in Slovenia, Titanium Grade 2 Angle Channel exporter in Spain, Titanium Grade 2 Angle Channel exporter in Sweden, Titanium Grade 2 Angle Channel exporter in Switzerland, Titanium Grade 2 Angle Channel exporter in Singapore

People Also Search For

SS Sheets Supplier India, SS Coils Supplier India, SS 304 coil price list, SS 304 cold rolled coil distributors, SS 304 profile dealers, SS 304 circle price list, SS 304 coil exporter in mumbai, ss 304 coil Supplier in India, SS 304 coil exporter in india, SS 304 coil-circle exporter in mumbai, ss 304 blank suppliers, SS 304 coils price, ss 304 circle price list, astm a240 ss 304 circles exporter, ss 304 shim coils, SS 304 coil supplier in mumbai, SS Plates Supplier India, , ss 304 coil cheap price, high quality ss 304 coils stockholder in mumbai india.